Large-size aluminium honeycomb board

A honeycomb aluminum plate, large-scale technology, used in covering/lining, layered products, chemical instruments and methods, etc., can solve the problem of heavy building materials, small thickness of ordinary aluminum plates, and can not meet the diversification and individual needs of decoration projects, etc. problems, to achieve the effect of light weight, good strength, and meet the needs of diversification and individualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

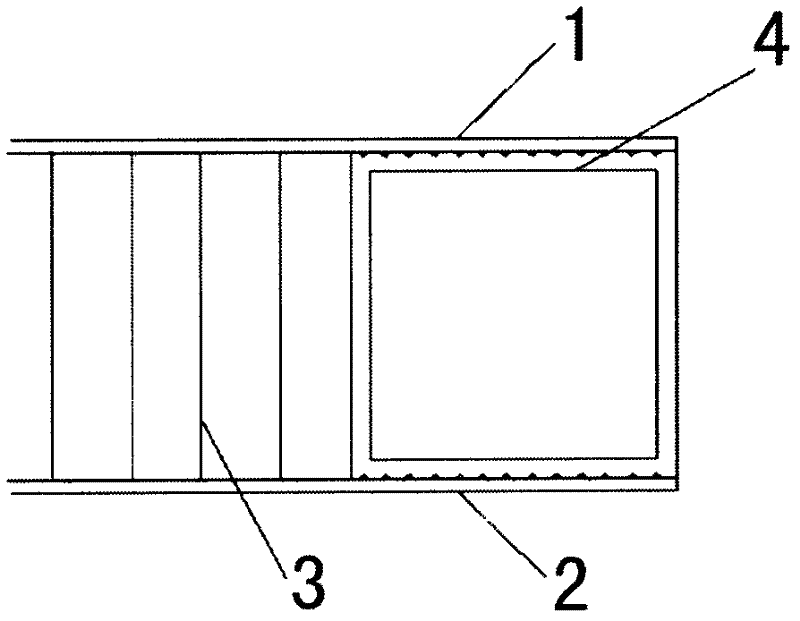

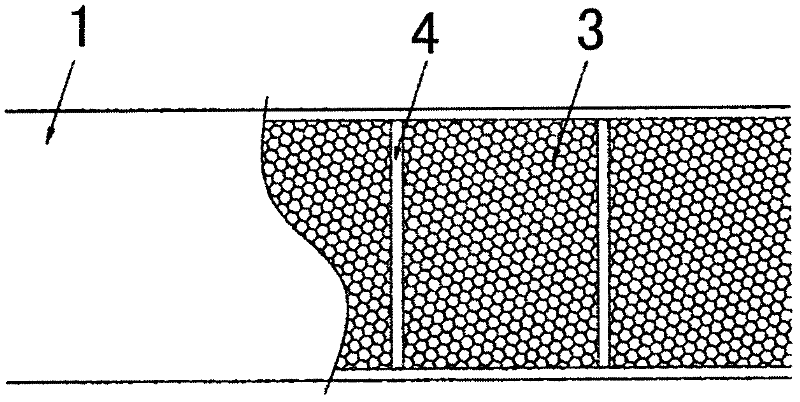

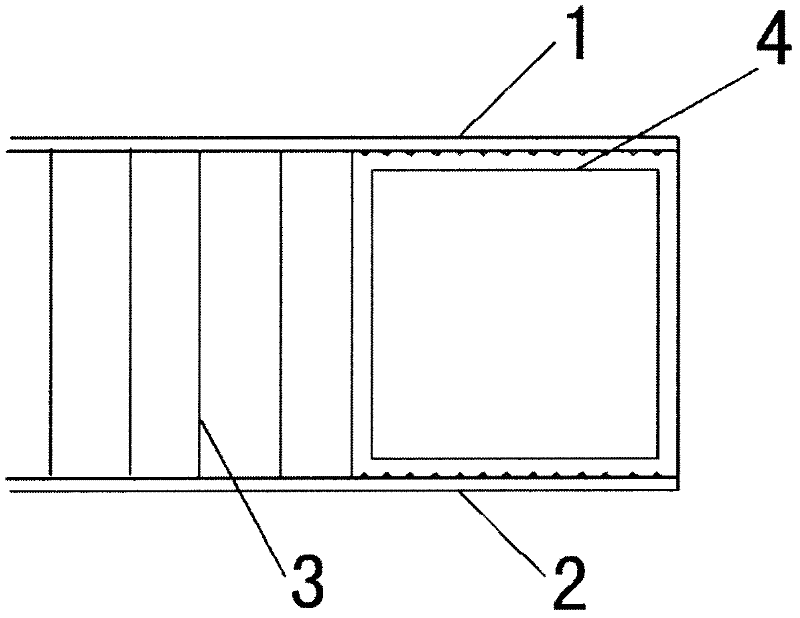

[0015] Example: such as figure 1 , figure 2 As shown, a large-scale honeycomb aluminum panel includes an aluminum veneer panel 1, an aluminum honeycomb panel 3, and an aluminum veneer bottom panel 2, and the aluminum veneer panel 1, aluminum honeycomb panel 3, and aluminum veneer bottom panel 2 The layers are sequentially composited into a three-layer composite structure honeycomb aluminum panel.

[0016] It also includes an aluminum keel 4 which is located between the aluminum veneer panel 1 and the aluminum veneer bottom plate 2 . Aluminum veneer panel 1 (aluminum veneer bottom plate 2) and aluminum honeycomb panel 3 and aluminum keel 4 are riveted firmly with rivets, and the joints are painted with high-strength adhesive before riveting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com