Testing fixture of position accuracy of back hole of exhaust pipe

A technology of position degree and exhaust pipe, which is applied in the direction of measuring device, adopting mechanical device, mechanical measuring device, etc., can solve the problems of multiple clamping points, deformation of exhaust pipe clamp, complex shape of exhaust pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

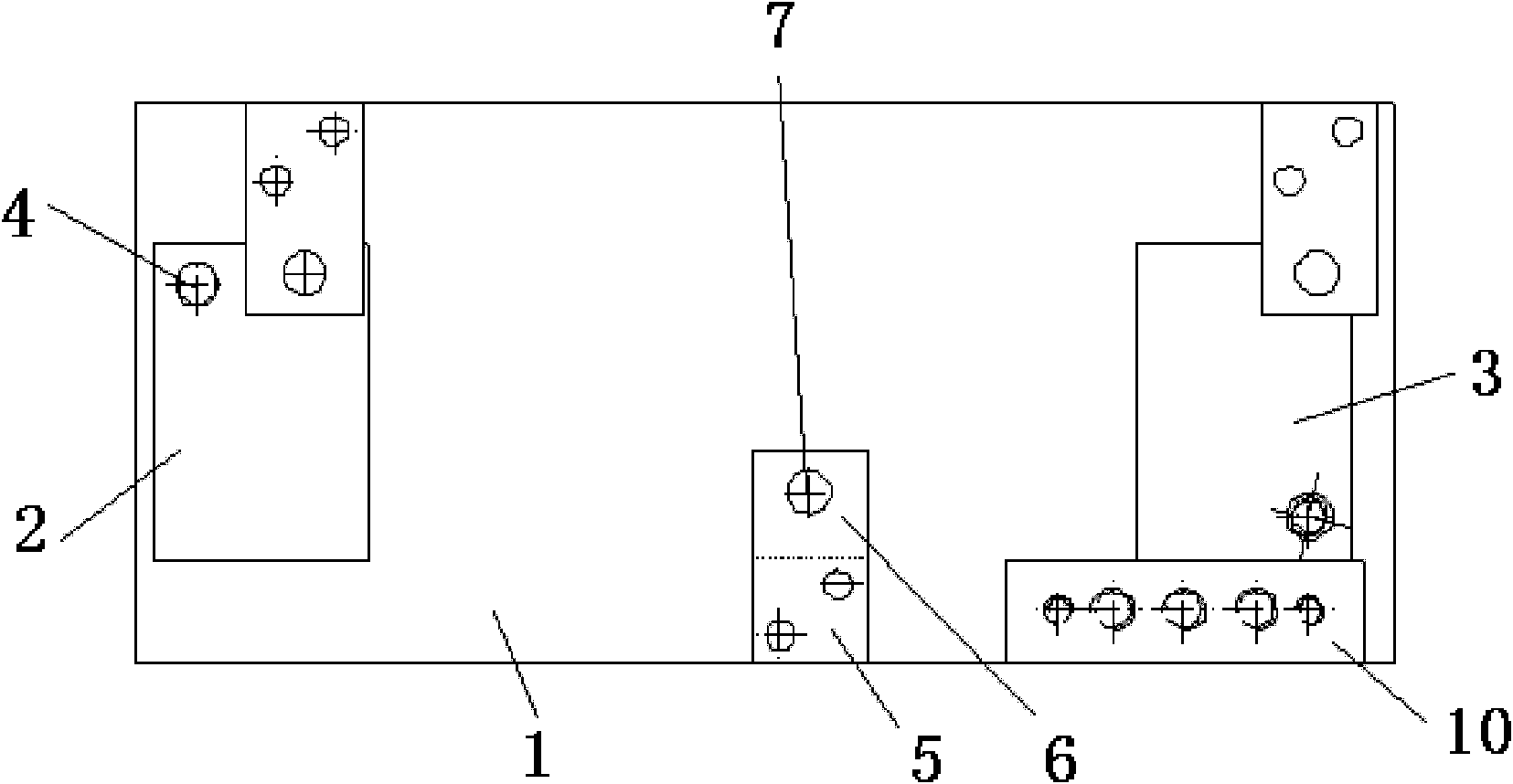

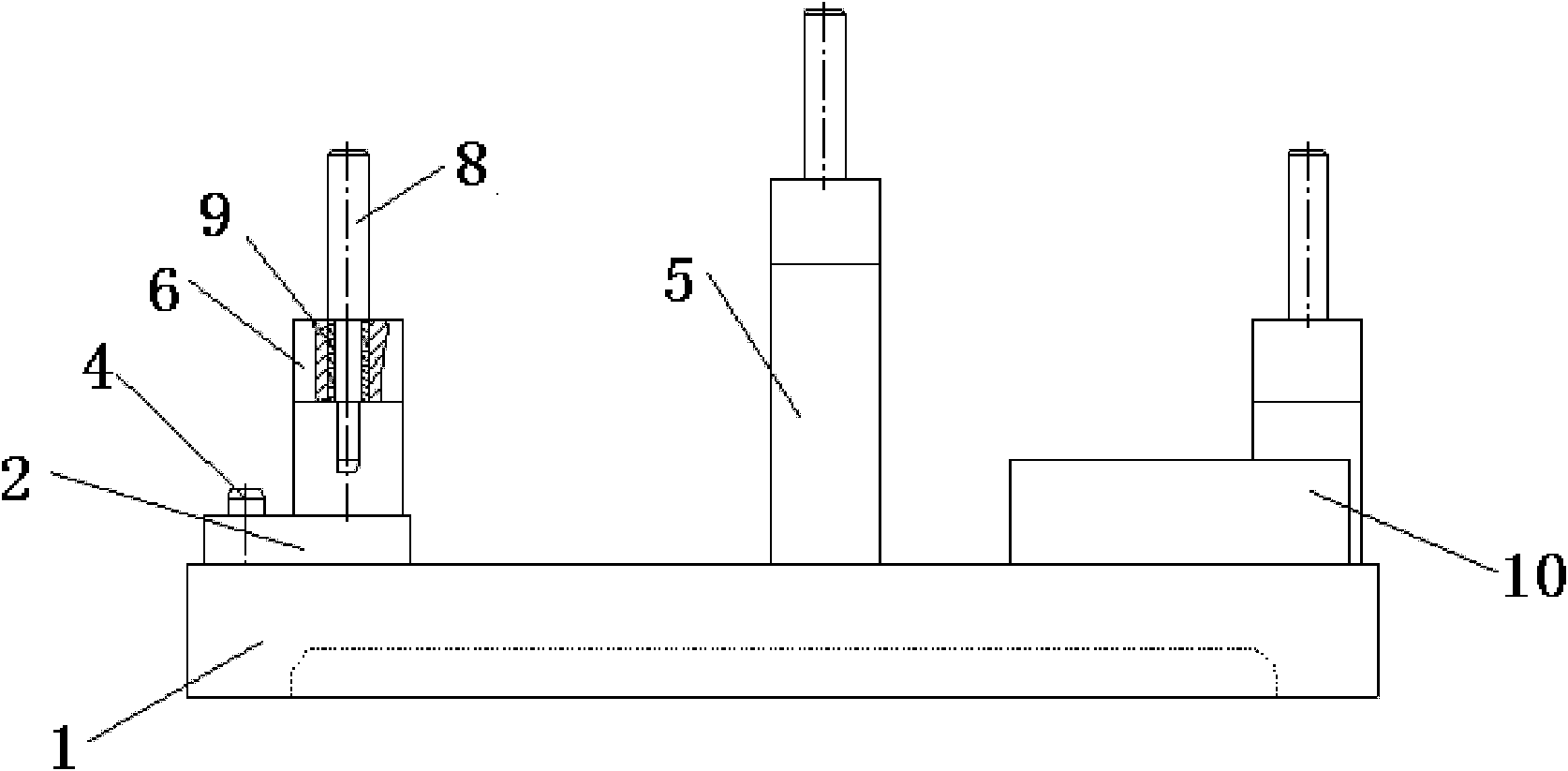

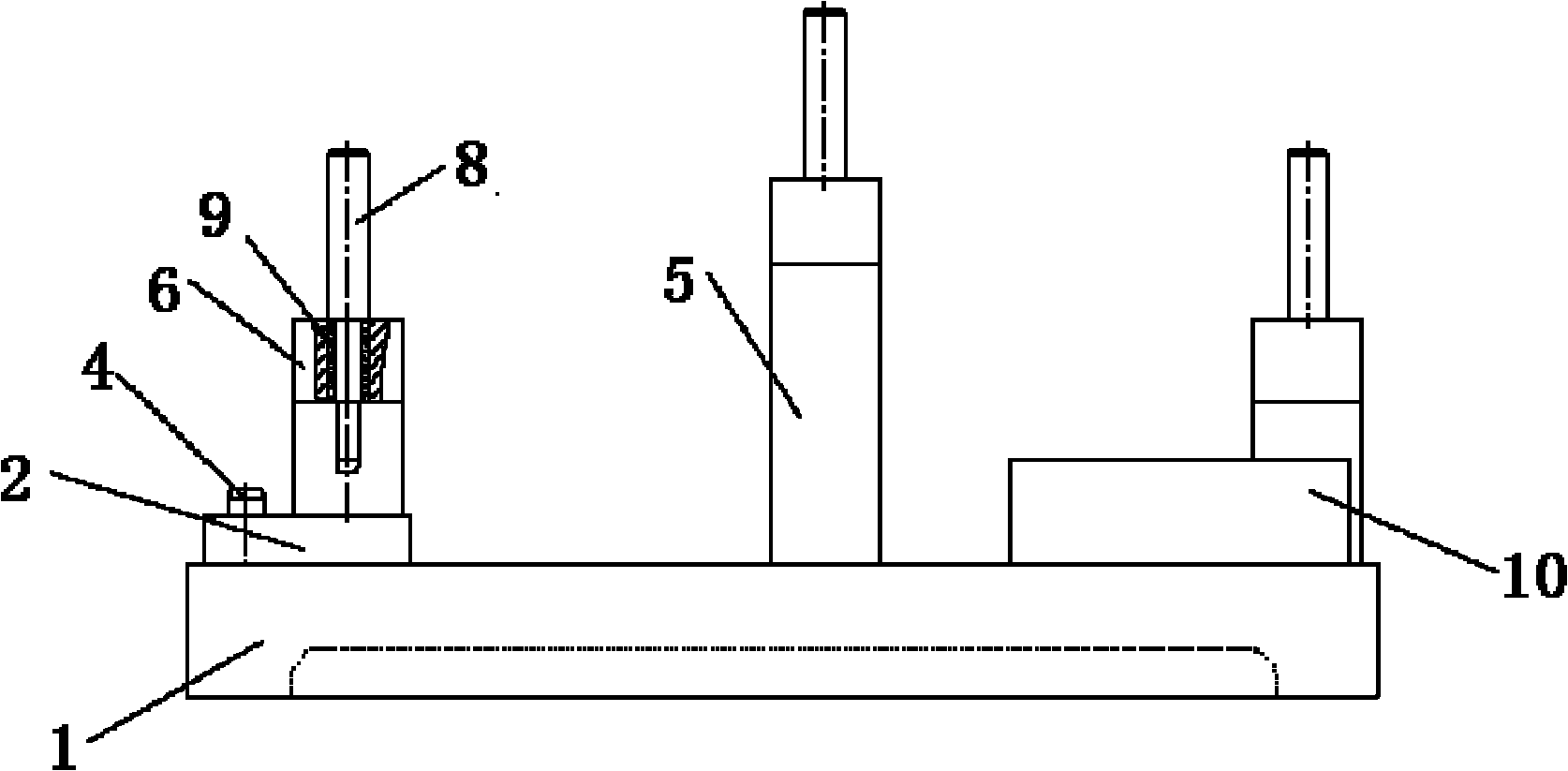

[0010] Referring to the accompanying drawings, a position inspection tool for the hole on the back of the exhaust pipe includes a base plate 1, the left and right ends of the base plate 1 are respectively provided with pads 2, 3, and the pads 2, 3 are provided with cylindrical positioning pins 4. The left and right ends of the upper edge of the bottom plate 1 and the middle section of the lower edge are provided with a bracket 5, and the top of the bracket 5 is provided with a guide block 6, and the guide block 6 is provided with a pin hole 7, and the A latch 8 is provided in the latch hole 7 , a guide sleeve 9 is provided on the inner wall of the latch hole 7 , and a latch plate 10 is provided at the bottom right of the bottom plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com