Sample liquid metering device

A liquid measurement and liquid technology, which is applied in measurement devices, liquid/fluid solid measurement, volume measurement instruments/methods, etc. Error factor, effect of high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

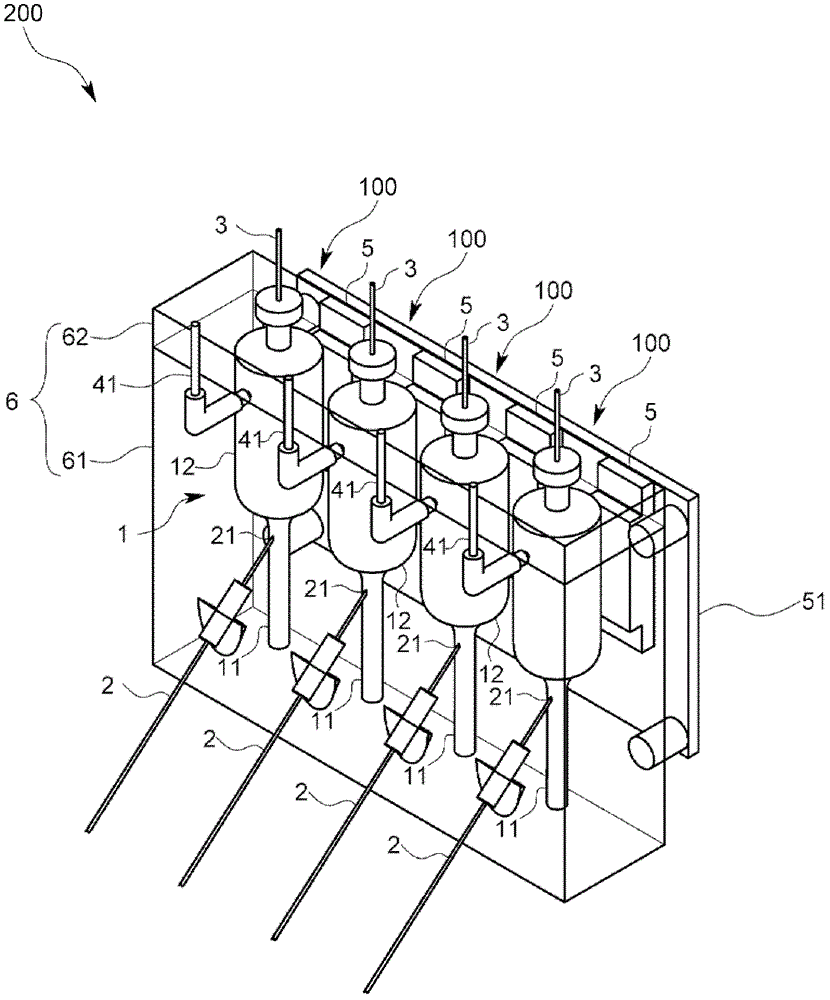

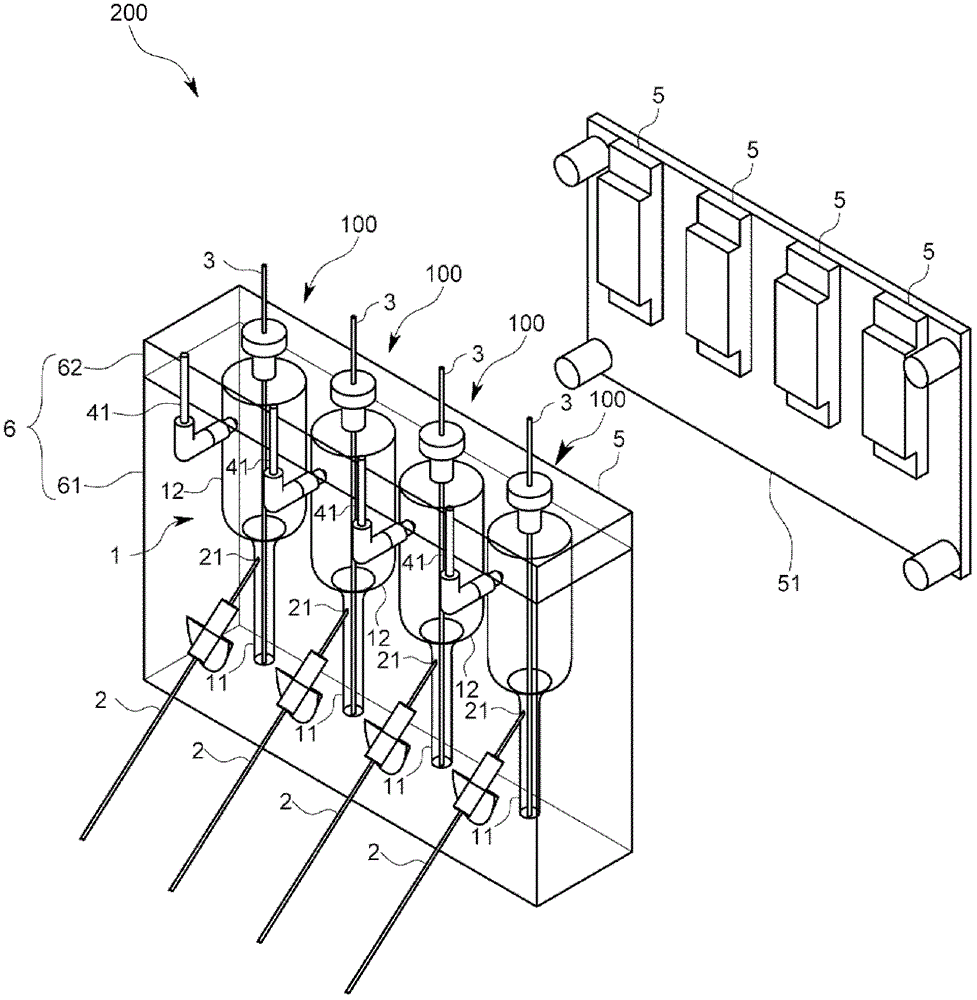

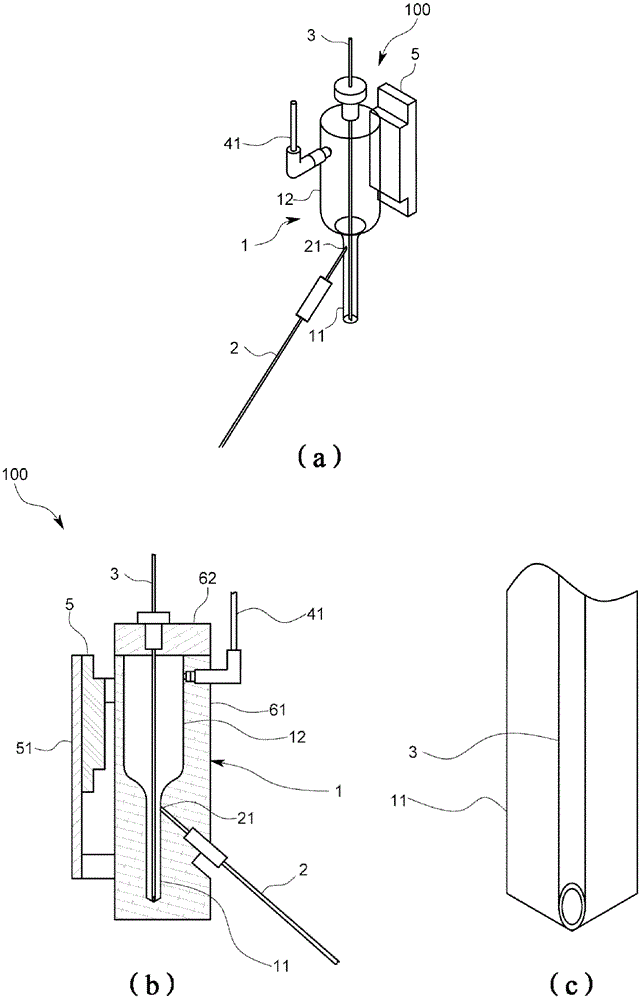

[0035] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

[0036] Such as figure 1 with figure 2 As shown in the perspective view of , the sample liquid measuring device 100 of this embodiment is constituted by connecting various pipes to the measuring container 1 which is dug vertically by cutting a transparent polyvinyl chloride cuboid 6 formed by holes. The sample liquid metering system 200 is constituted by forming four sample liquid metering devices 100 on one polyvinyl chloride rectangular parallelepiped 6 . The sample liquid metering system 200 is used to measure reagents used in, for example, COD measurement, and each sample liquid metering device 100 measures different reagents and sends the reagents to reaction tanks containing measurement objects. Also, for ease of understanding, figure 1 In the figure, the dotted line is also removed from the portion where the measurement container 1 is actually visible bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com