Swing-type power tool

A technology of swinging power tools and reciprocating swings, applied in electric components, casings/covers/supports, controlling mechanical energy, etc., can solve the problems of harmful user's hand health, large vibration, numb hands, etc., and improve the vibration and numb hands. Problems, vibration reduction, effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

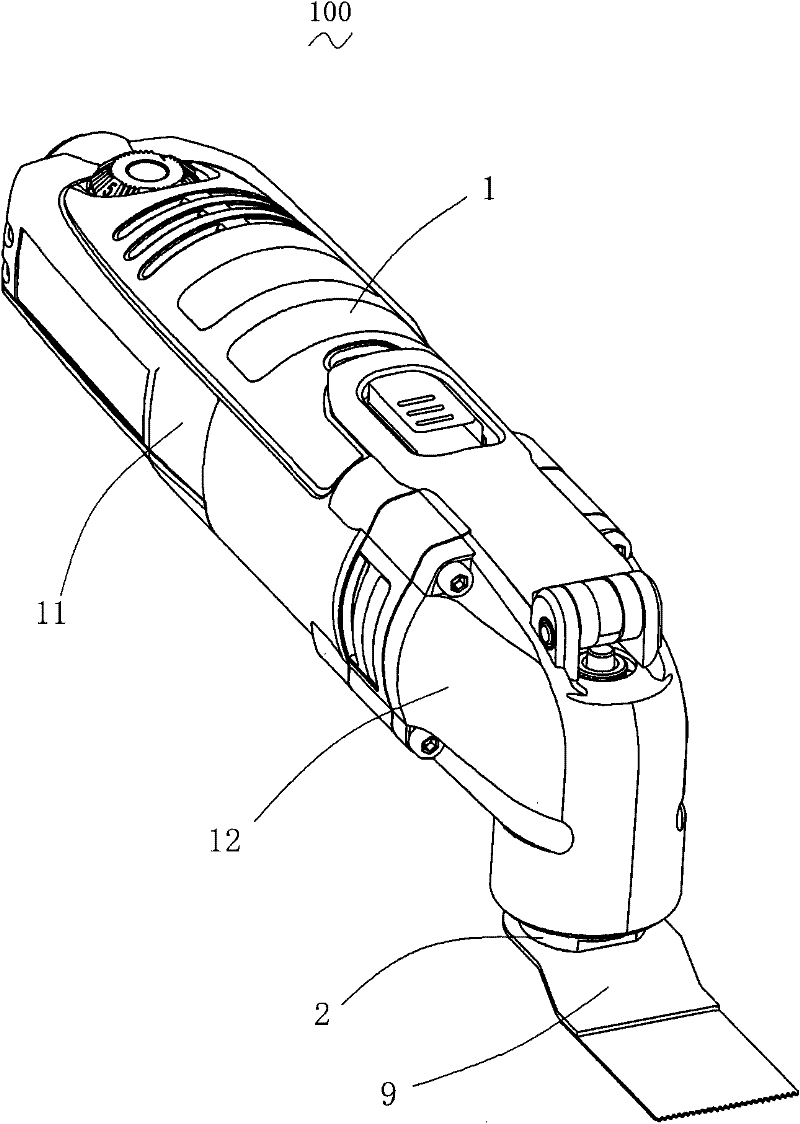

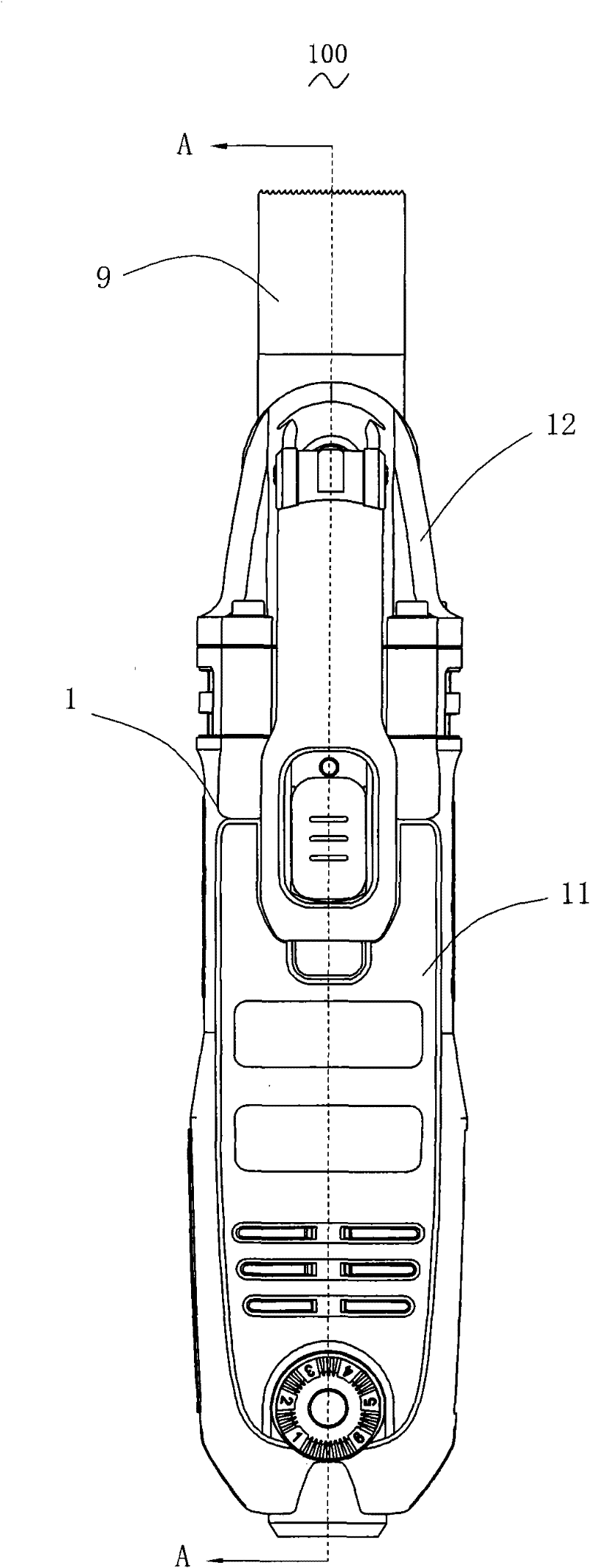

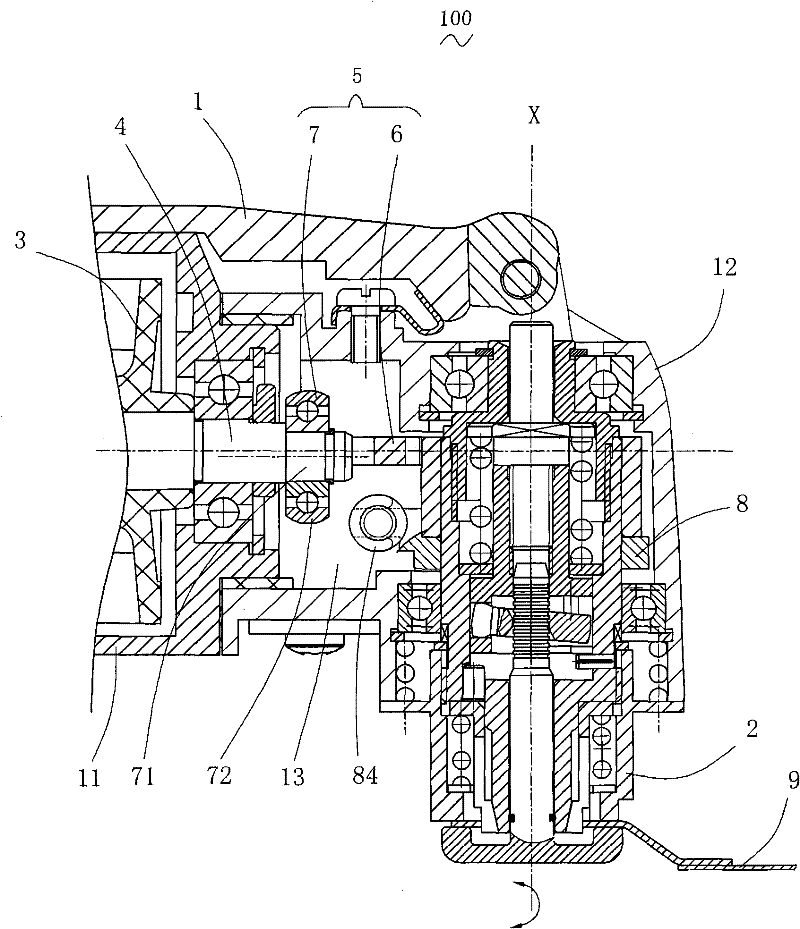

[0038] see figure 1 , figure 2 and image 3 , an oscillating power tool, especially a hand-held oscillating power tool 100 , includes a housing 1 and an output shaft 2 extending from the housing 1 . Wherein, the shell 1 includes a body shell 11 and a head shell 12 , which are connected together by bolts and form a receiving cavity 13 . The body shell 11 is provided with a motor 3 and a motor shaft 4 driven to rotate by the motor 3 , and the head case 12 is provided with an eccentric transmission mechanism 5 between the motor shaft 4 and the output shaft 2 . The motor shaft 4 is substantially perpendicular to the output shaft 2 , and the rotation of the motor shaft 4 is converted into the rotation and reciprocating swing of the output shaft 2 around its axis X through the eccentric transmission mechanism 5 . When the free end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com