Elastomeric joint

一种弹性体、铰链的技术,应用在弹簧、装在枢轴上的悬臂、电路等方向,能够解决脱离、锁紧圈脱离、支承环疲劳断裂等问题,达到低制造成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

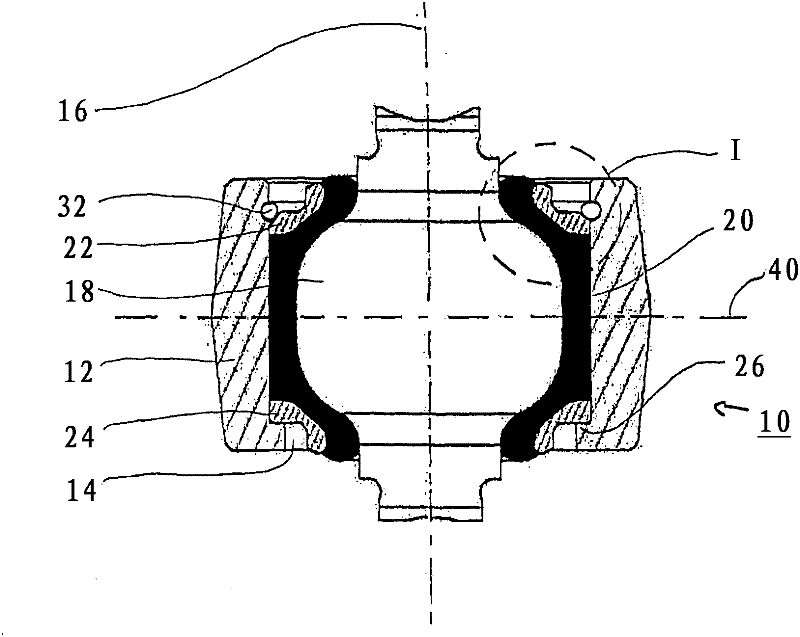

[0035] Figure 11 A lateral cross-sectional view of a conventional elastomer hinge 1 is shown. The elastomeric hinge 1 has a housing 12 with a through opening 14 which extends axially along a longitudinal axis 16 of the elastomeric hinge 10 . A hinge pin 18 extends through the through-opening 14 or is accommodated therein. An elastomer body 20 is fastened to the outer circumference of the hinge pin 18 , with its outer circumference resting against the inner circumference of the housing 12 in the central region of the elastomer hinge 1 . The elastomer body 20 can be fixed on the hinge journal 18 or on the inner peripheral surface of the housing 12 by vulcanization, adhesive bonding or the like. By means of the elastomer body 20 , a rotational movement and / or a universal movement of the hinge pin 18 relative to the housing 12 about the longitudinal axis 16 (ie in the path of a tilting movement about the longitudinal axis 16 ) is possible.

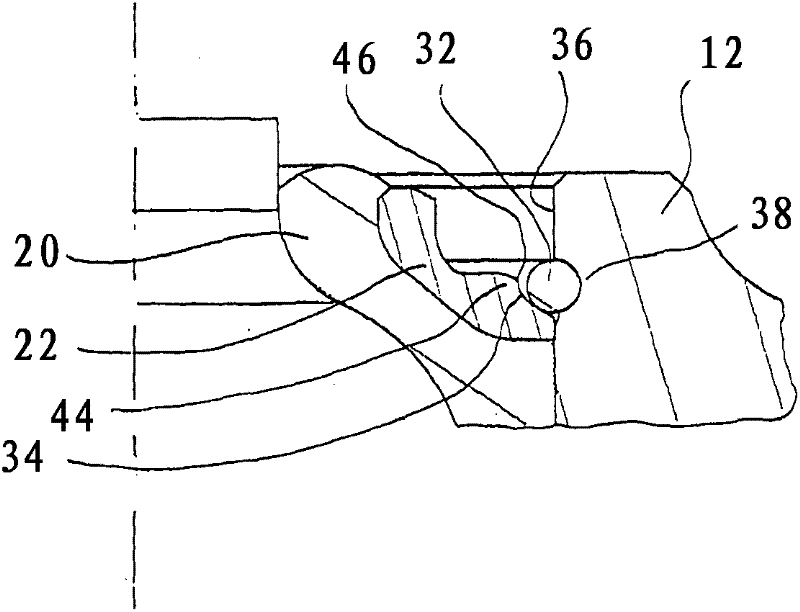

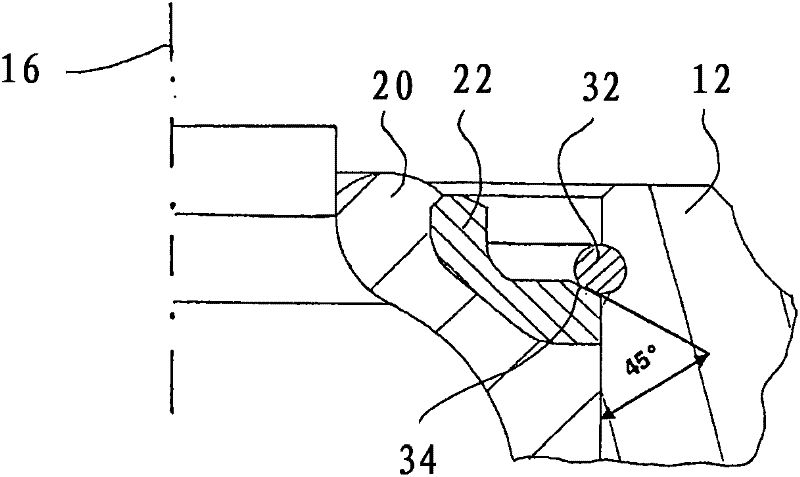

[0036] An upper support ring 22 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com