Process for liquefying a hydrocarbon-rich stream

A post-liquefaction, hydrocarbon-enriched fraction technology, applied in liquefaction, refrigeration and liquefaction, irreversible cycle compressors, etc., can solve the limitation of intervention possibilities or the number of degrees of freedom, and the difficulty of targeted adjustment and adjustment of temperature curves, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

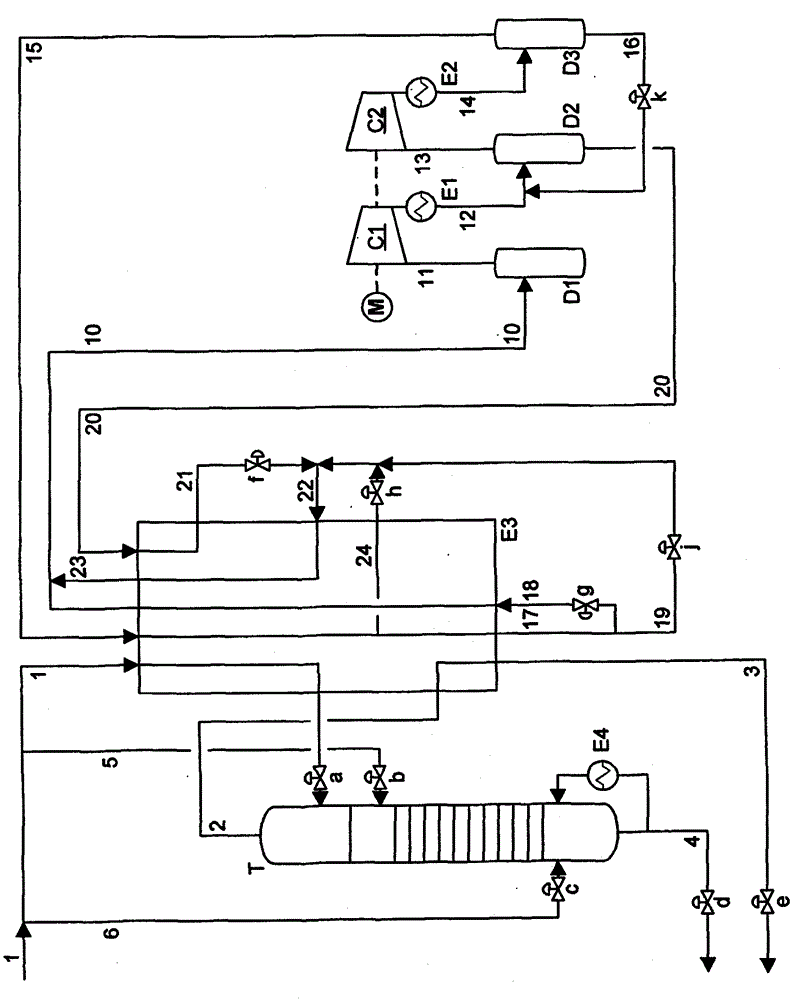

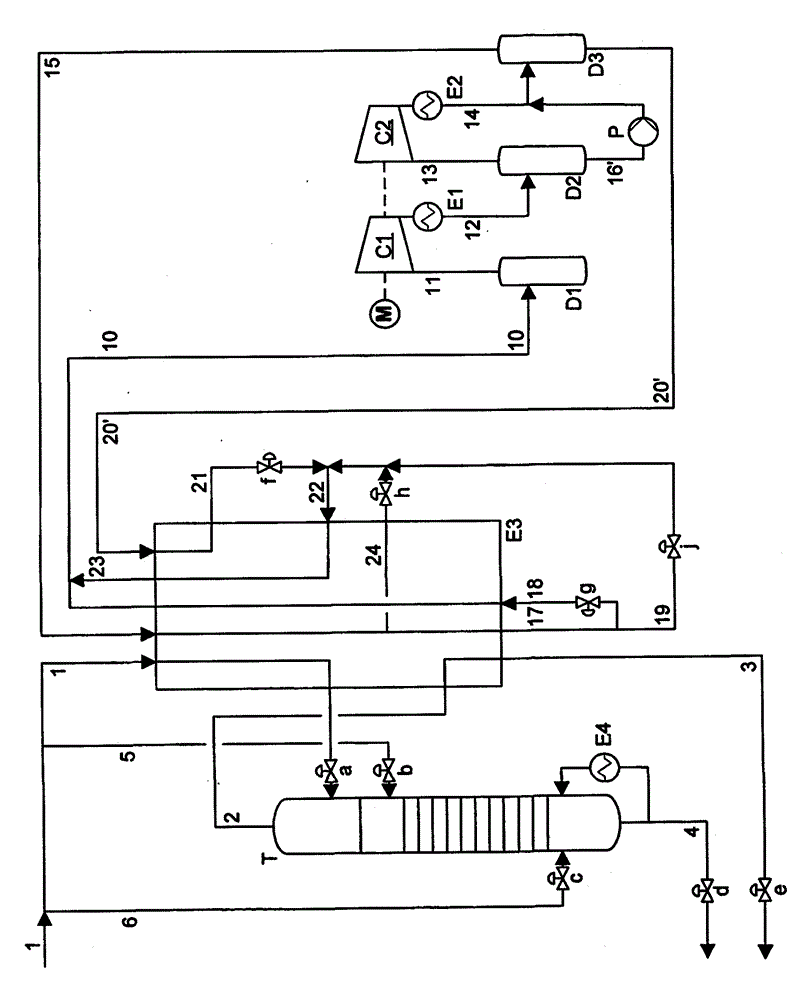

[0013] Explained below figure 2 The embodiment shown in only describes and figure 1 The difference between the methods shown in.

[0014] The method for liquefying hydrocarbon-rich fractions of the present invention figure 1 with 2 The embodiment shown in has a separation tower T, which is used to remove C 2+ The fraction is separated from the hydrocarbon-rich fraction to be liquefied. The fraction to be liquefied is referred to as a natural gas stream in the following and is supplied to the multi-stream heat exchanger E3 via the line 1.

[0015] The multi-stream heat exchanger is preferably configured as a welded aluminum plate heat exchanger. According to the size of the equipment, 1 to 6 heat exchanger units connected in parallel are preferably arranged. Alternatively, the multi-stream heat exchanger E3 may also be configured as a wound heat exchanger. Here, the aluminum plate heat exchanger is preferably used for the liquefaction capacity with an annual output of 30,000 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com