Device for automatic in-line measurement of mass loss by calcination and thermal decomposition of solid particles

A technology of solid particles and loss on ignition, applied in measuring devices, material thermal analysis, testing water, etc., can solve problems such as the influence of property changes, increased frequency of occurrence, and large uncertainty in measured values, so as to avoid trouble, Optimizing response time, avoiding effects of deterministic weight measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

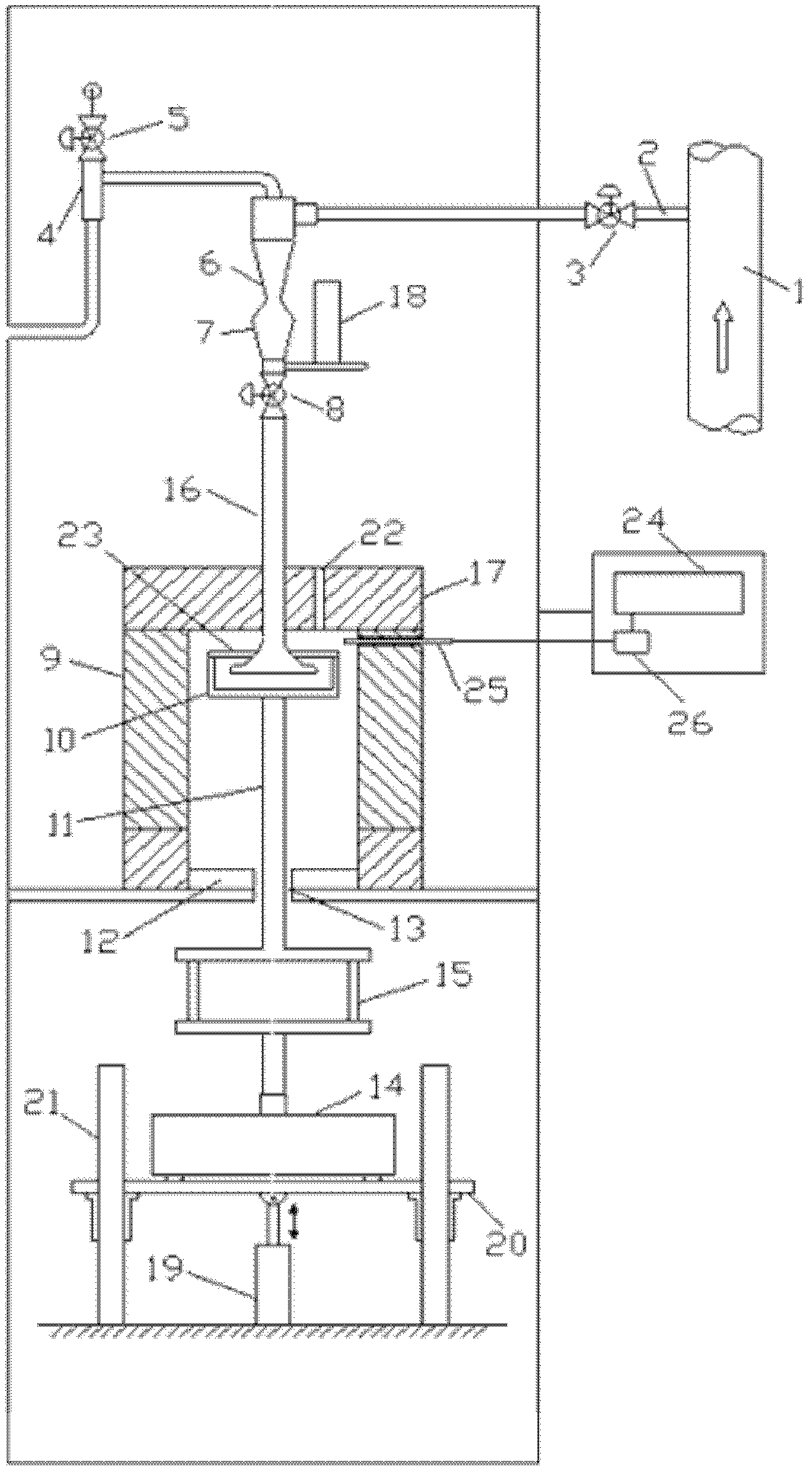

[0029] figure 1 A schematic representation of one embodiment of the invention claimed is shown. The structure of the device makes it possible to measure the loss on ignition both in an oxygen-free environment and in an oxygen-free environment.

[0030] In the example shown, the device for in-line measurement of loss on ignition and thermal decomposition reactions is connected to a pneumatic particle transport conduit 1 via a transport pipe 2 provided with an automatic shut-off valve 3 . The device uses a jet pump 4 supplied with compressed air through a self-closing valve 5 to absorb a bidirectional air flow consisting of a mixture of particles to be detected and air for transport. The extracted particles are separated by a cyclone dryer 6 and collected into a chamber 7 which is isolated at the lower end by a self-closing valve 8 .

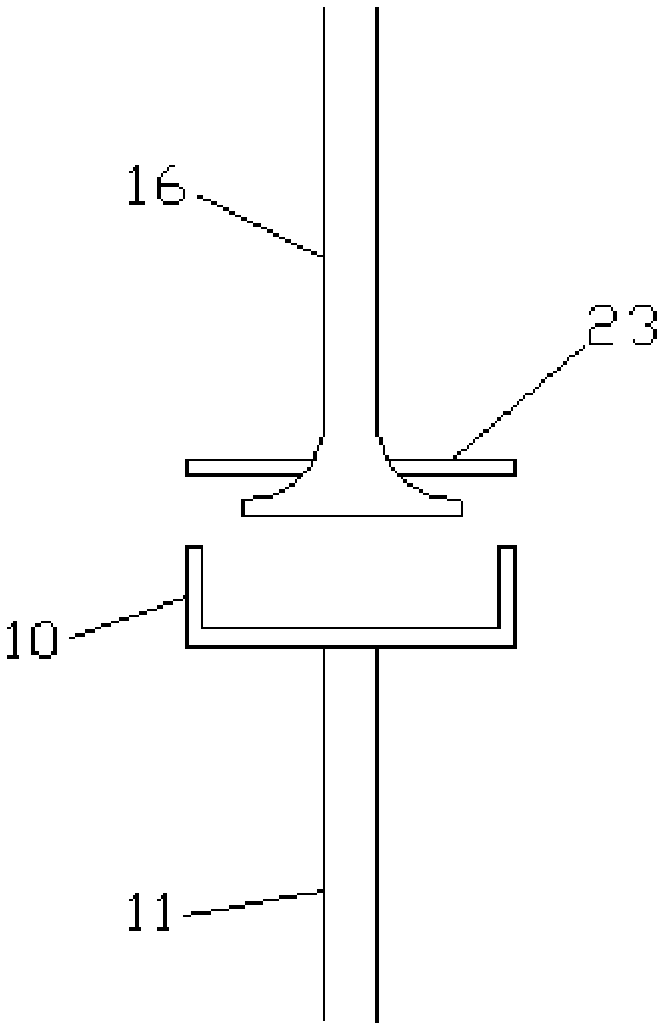

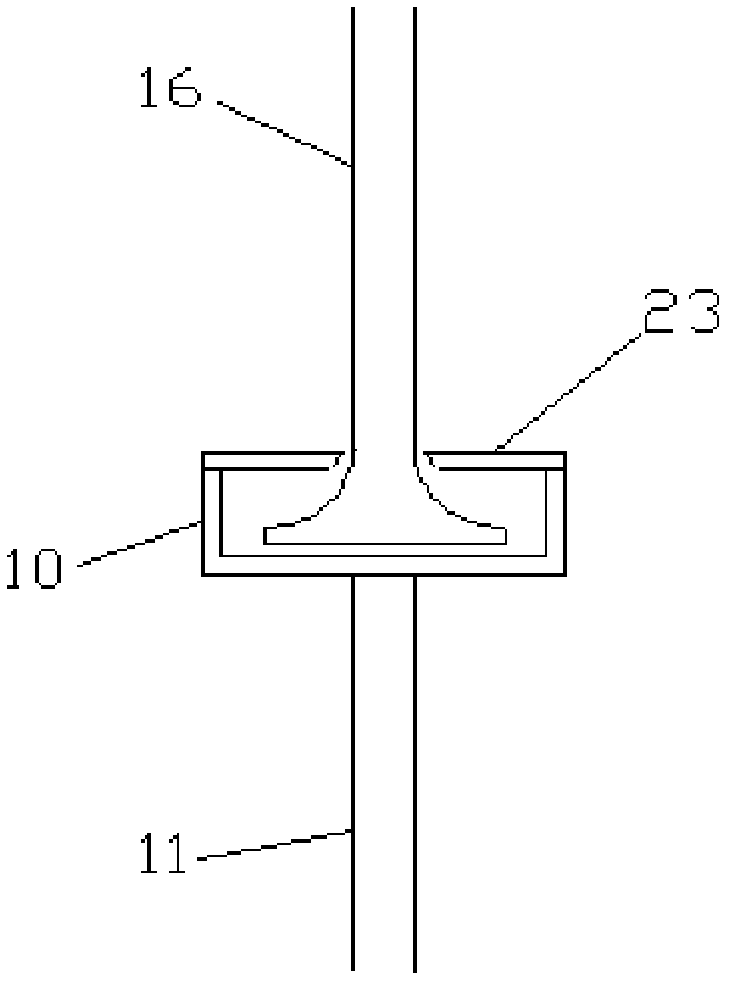

[0031] The cyclone drier 6, the chamber 7 and the valve 8 are arranged vertically and in line above the electric furnace 9, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com