Systems and methods of improved heat dissipation with variable pitch grid array packaging

A technology of spacing and packaging, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems that affect product profits, high cost, and affect device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Description of the implementation

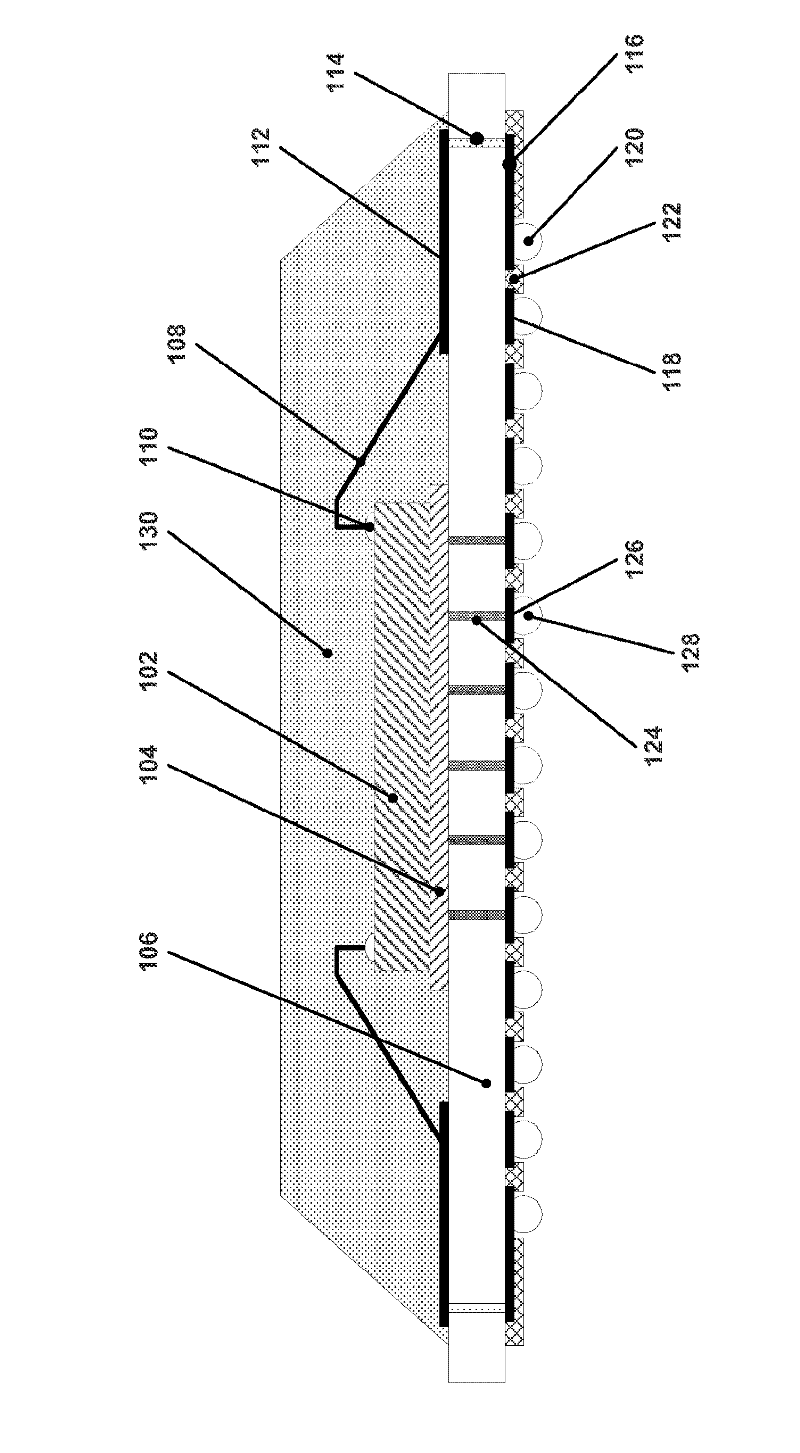

[0045] A detailed description of embodiments of the invention is provided below. While the present disclosure is described in connection with these figures, there is no intention to limit it to the embodiments disclosed herein. On the contrary, the intention is to cover all other alternatives, modifications and equivalents as included within the spirit and scope of the present disclosure as defined by the appended claims.

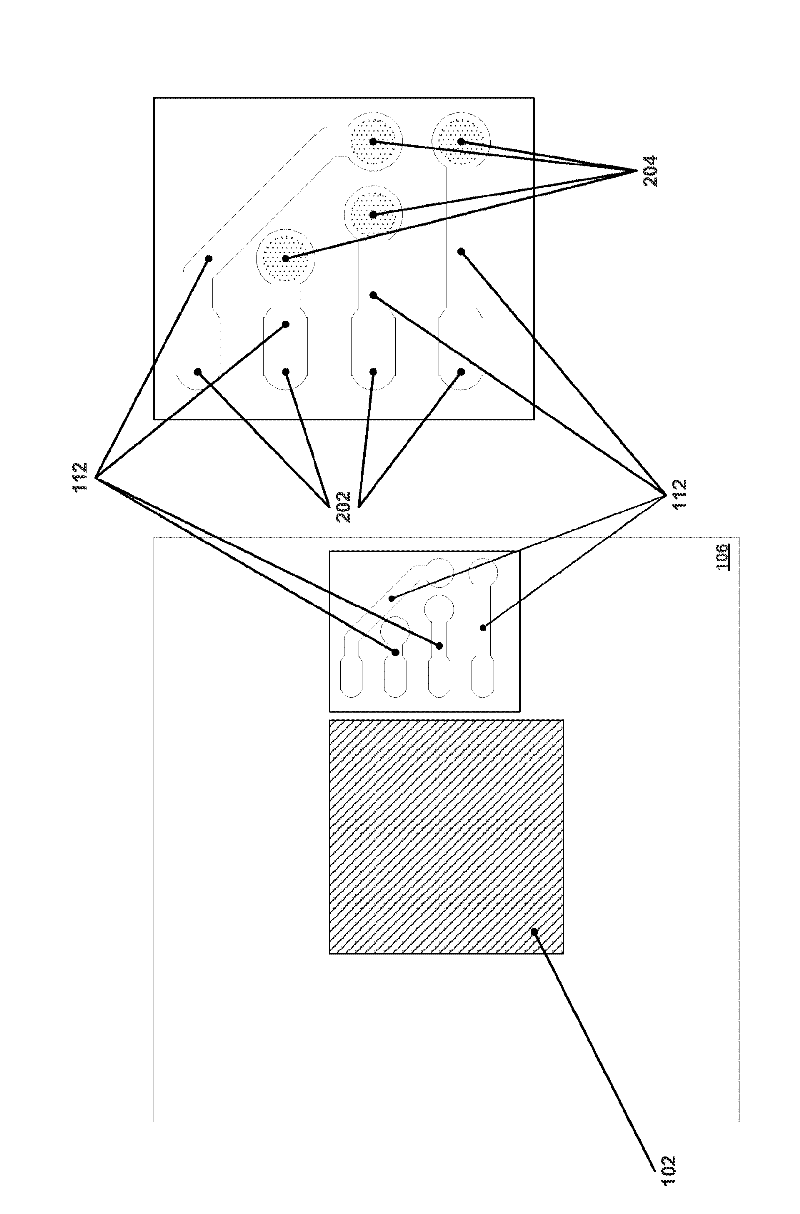

[0046] Figure 9 shows a bottom view of a package with variable pitch I / O interfaces. The package can use any of the array technologies like BGA, PGA and / or LGA, but for the purposes of this article, the BGA example is used. Also, a package similar to that described in FIG. 1 is used as an example. However, one of ordinary skill in the art will understand the applicability of choosing array packages such as PGA and LGA and different BGA configurations such as CBGA and flip-chip BGA.

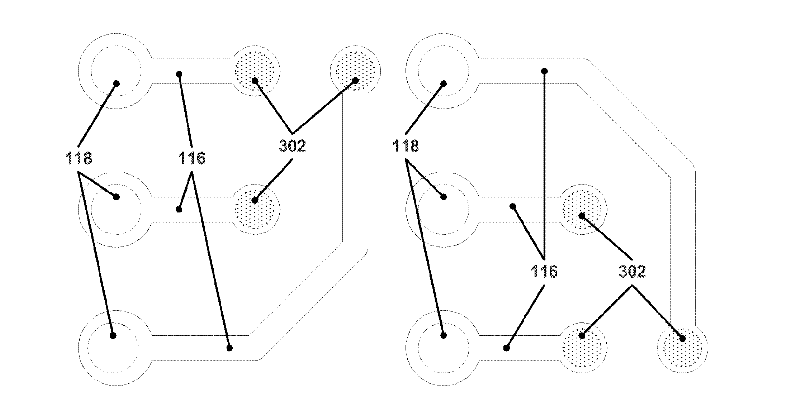

[0047] exist Figure 11 In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com