Hanging device structure

A technology of hanger and hanging part, which is applied in the direction of supporting machines, other household appliances, household components, etc., and can solve problems such as large thread stress positive friction force, screw cannot move, laborious rotation and level adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The detailed description and technical content of the present invention will be described as follows with the accompanying drawings, but the attached drawings are only for illustration purposes and are not intended to limit the present invention.

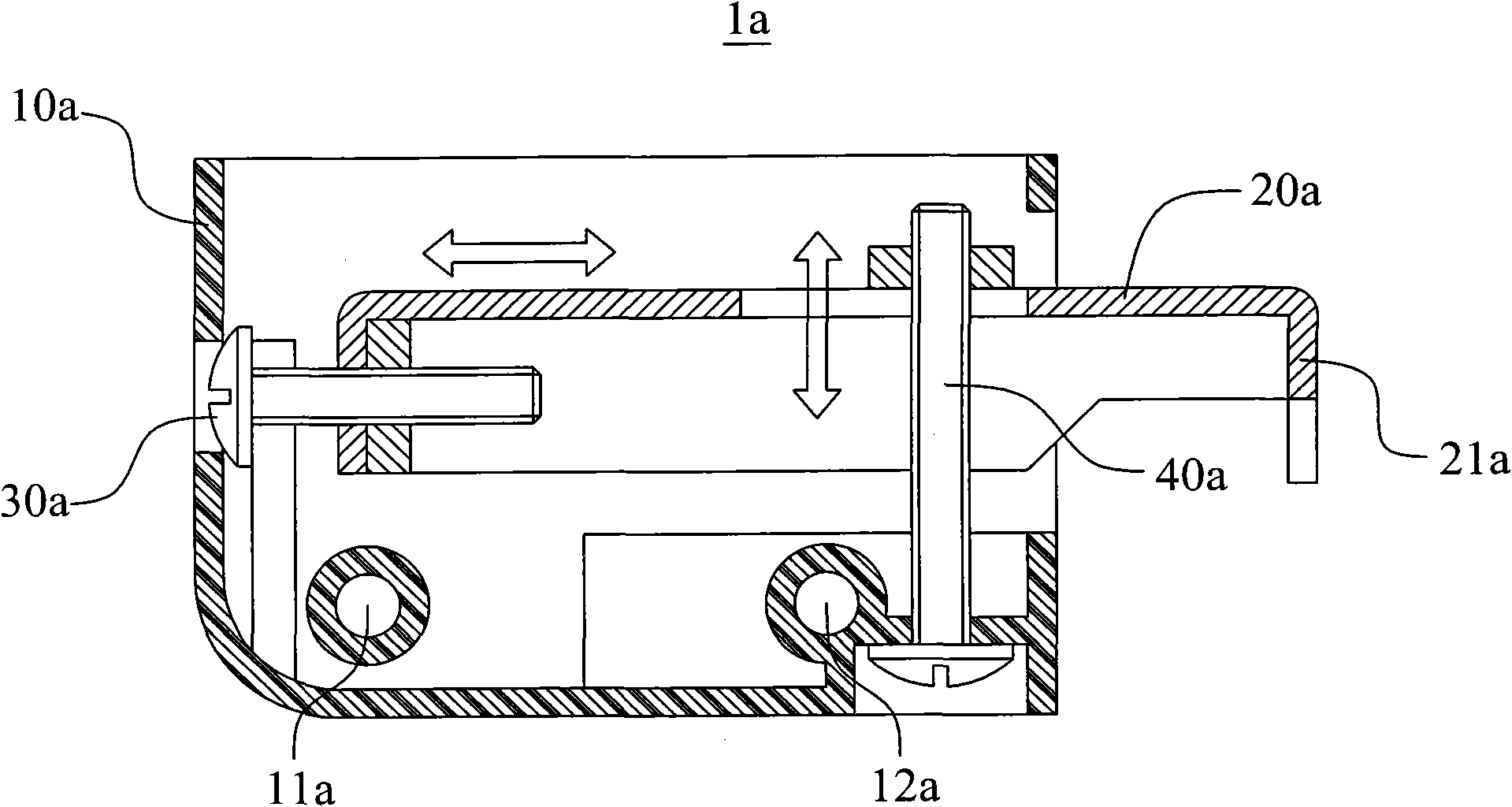

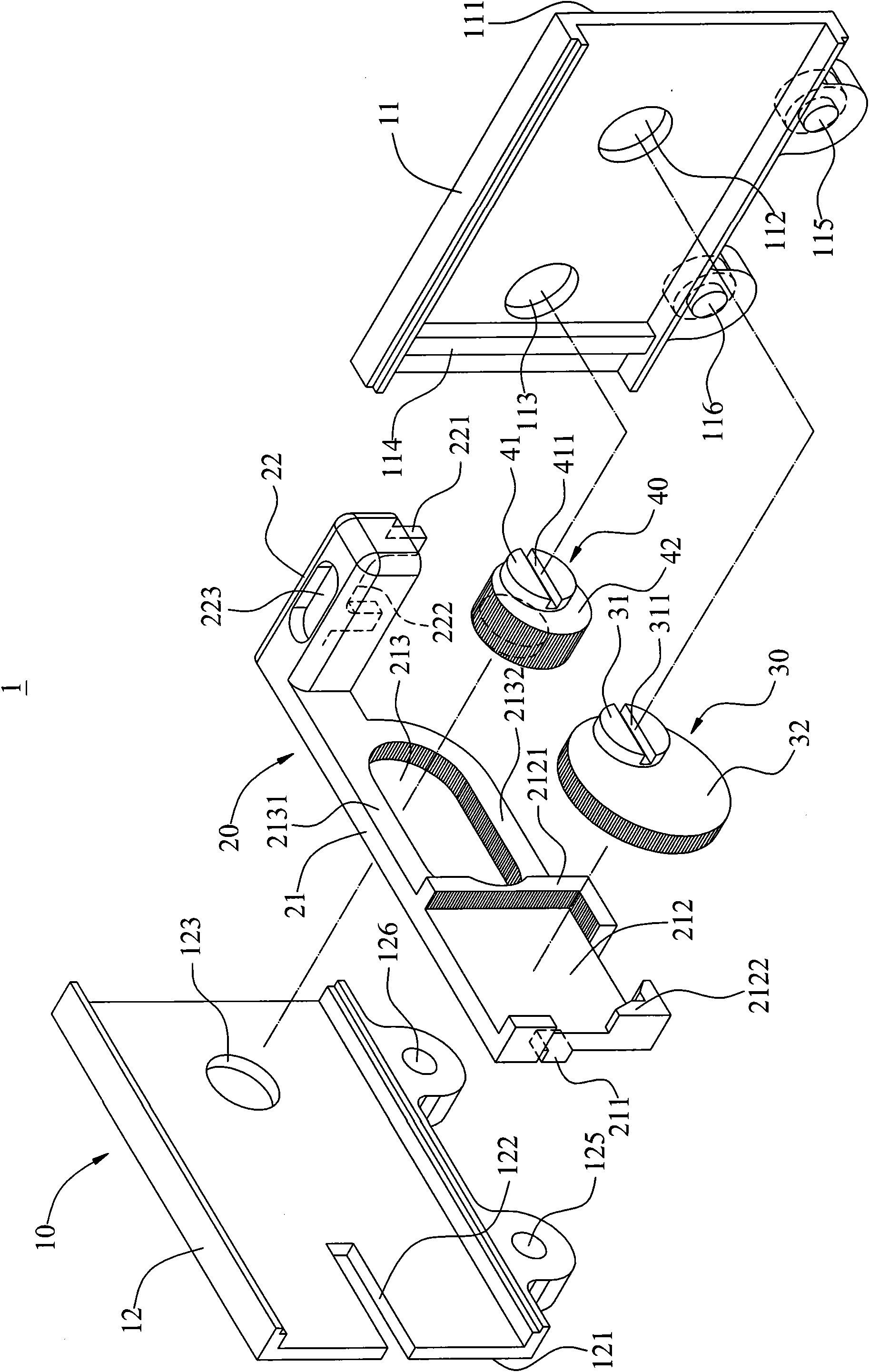

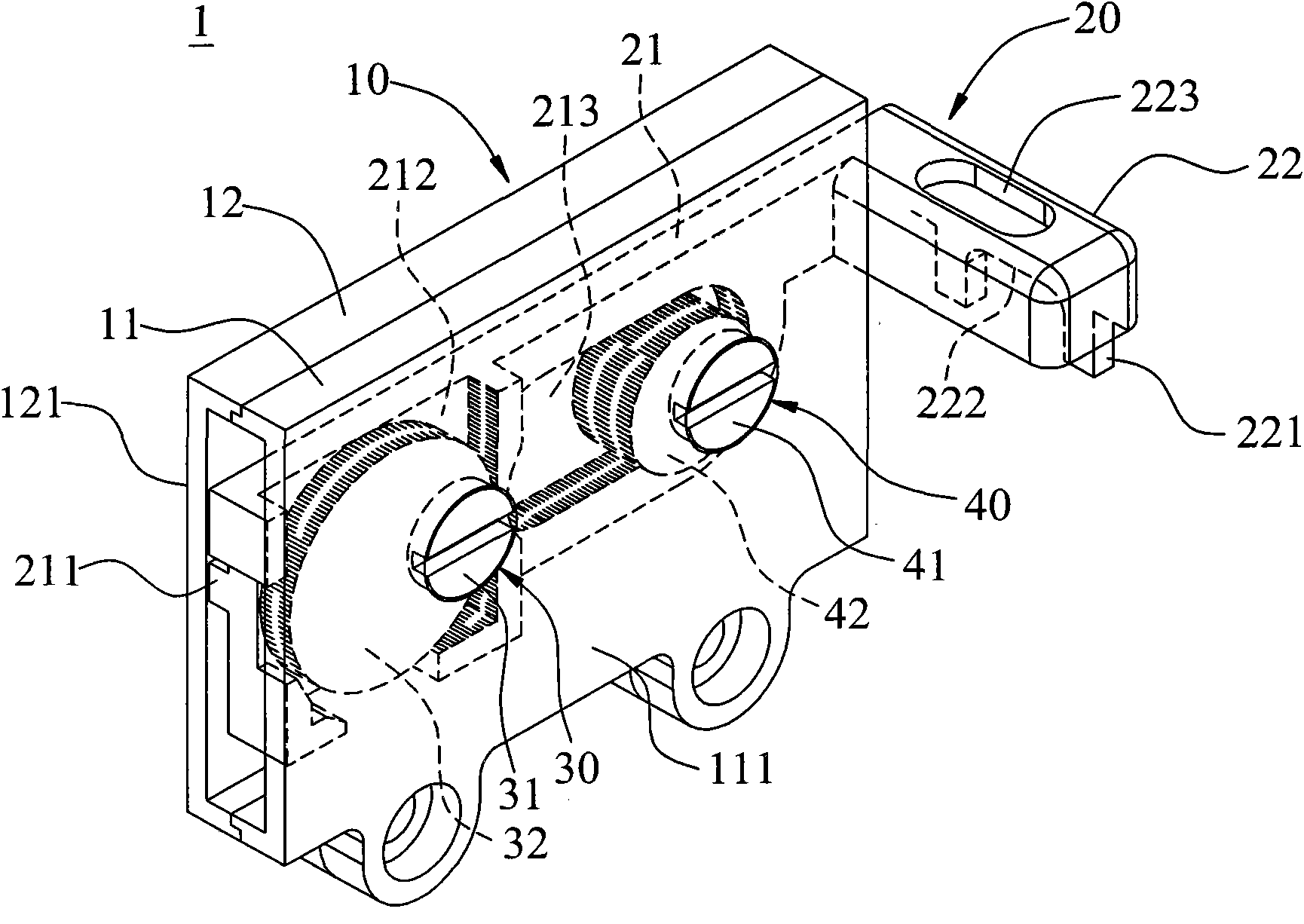

[0068] Please refer to Figure 2 to Figure 4 , the present invention provides a hanger structure 1 , the hanger structure 1 mainly includes: a housing 10 , a hanger 20 , a horizontal adjustment mechanism 30 and a vertical adjustment mechanism 40 . like Figure 8 and Figure 9 As shown, the hanger structure 1 is used to hang the cabinet 100 on the support 300 of the wall 200 .

[0069] exist figure 2 In the shown embodiment, the housing 10 is composed of a front shell 11 and a rear shell 12, the front shell 11 has an adjustment surface 111, a first hole 112 and a second hole 113, and the rear shell 12 has a mounting surface 121, a guide The guide groove 122 and the third hole 123; in other words, the housing 10 has an adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com