Method for preparing glycol monoether from ethylene

A technology of ethylene glycol monoether and ethylene, which is applied in the preparation of ether from alkylene oxide, chemical instruments and methods, and preparation of ether, which can solve the problems of catalyst consumption, affecting product quality, complicated process, etc., and improve reaction selectivity , reduce the occurrence of side reactions, improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

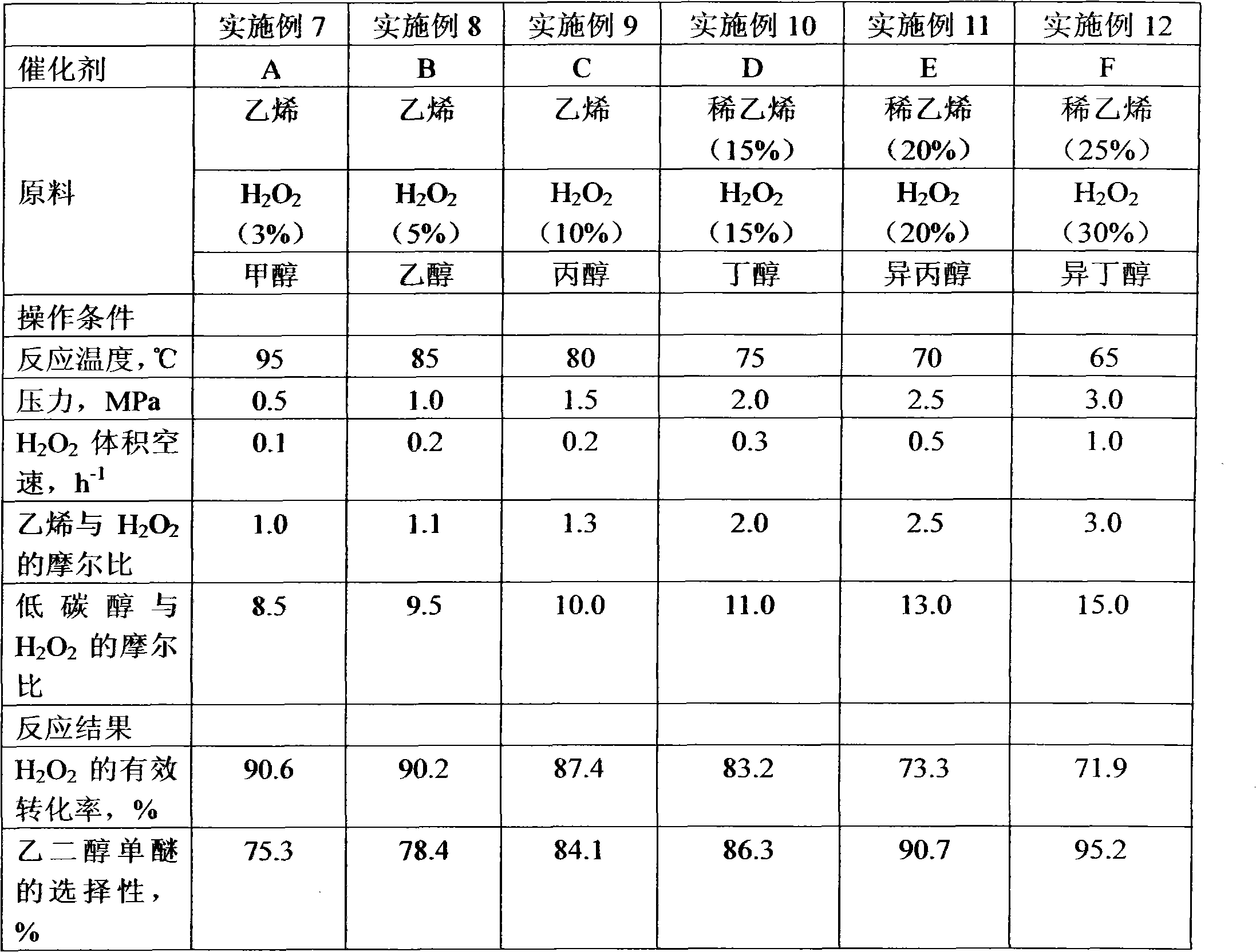

Examples

Embodiment 1

[0044] In the polymerization kettle, add 5.5g of titanium-silicon molecular sieve powder, 1g of Hβ zeolite, 90g of polymerized monomer styrene and 30g of divinylbenzene, 60g of pore-forming agent liquid wax, stir and mix evenly, when the temperature of the water bath is raised to 60°C, add The initiator was 1.5 g of benzoyl peroxide, and the polymerization reaction temperature was 90° C. for 6 hours to obtain a block titanium-silicon molecular sieve composite catalyst. Then carry out crushing and granulation, select a catalyst with a suitable particle size after screening, add 250 ml of 1,2-dichloroethane to swell, and swell for 5 hours at normal temperature. After pouring out 1,2-dichloroethane, add 200ml of ethyl acetate for solvent extraction, the extraction reaction temperature is 55°C, and the extraction time is 4 hours. The same method is used for three extractions to obtain the titanium-silicon molecular sieve composite catalyst A , and its physical and chemical propert...

Embodiment 2

[0046] In the polymerization kettle, add 15g of titanium-silicon molecular sieve powder, 3g of H-ZSM-5 molecular sieve, 90g of polymerized monomer styrene, 15g of divinyltoluene, 25g of divinylxylene, and pore-forming agent C 5 60g of aliphatic alcohol, stirred and mixed evenly, when the temperature of the water bath was raised to 80°C, 2.0g of initiator azobisisobutanol was added, and the reaction temperature was polymerized at 100°C for 6 hours to obtain a block titanium silicon molecular sieve catalyst. Then carry out crushing and granulation, select a catalyst with a suitable particle size after screening, add 250 ml of 1,2-dichloroethane to swell, and swell for 5 hours at normal temperature. After pouring out the 1,2-dichloroethane, add 200ml of xylene to carry out solvent extraction, the extraction reaction temperature is 55°C, and the extraction time is 4 hours. The same method is used for three extractions to obtain the titanium-silicon molecular sieve composite catalys...

Embodiment 3

[0048] The weight of the titanium-silicon molecular sieve powder in Example 1 was changed to 30 g, and 3 g of mordenite was added, and the rest was the same as in Example 1 to obtain a titanium-silicon molecular sieve composite catalyst C, whose physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com