High-efficiency damping backing plate

A vibration-damping pad and high-efficiency technology, which is applied in roads, tracks, buildings, etc., can solve problems such as high natural frequency, poor dimensional stability, and large dynamic/static stiffness ratio of the vibration-damping pad, so as to ensure safety, geometric Small dimensional change rate, widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The raw materials used in this patent are thermoplastic high-performance polyester elastomer compounding materials, which can be purchased as ready-made products by manufacturers. This patent is only to inject the above-mentioned raw materials in a mold by injection molding, and process them into products of predetermined structure. There is no special requirement for the production equipment of this product, and known equipment is sufficient.

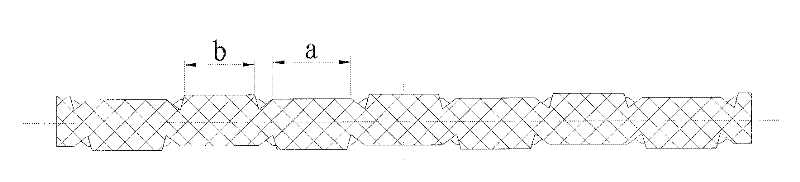

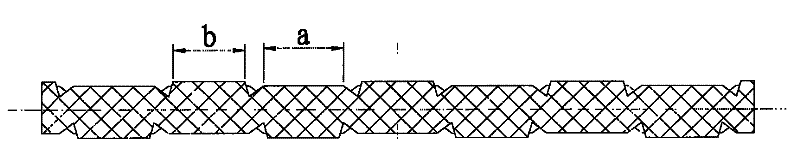

[0020] Please see figure 1 , which is a cross-sectional view of the structure of this patent, a hollow prism a and a solid prism b are integrally formed on the upper and lower sides of the backing plate, the upper and lower sides are misaligned with each other, and four hollow prisms surround one solid prism.

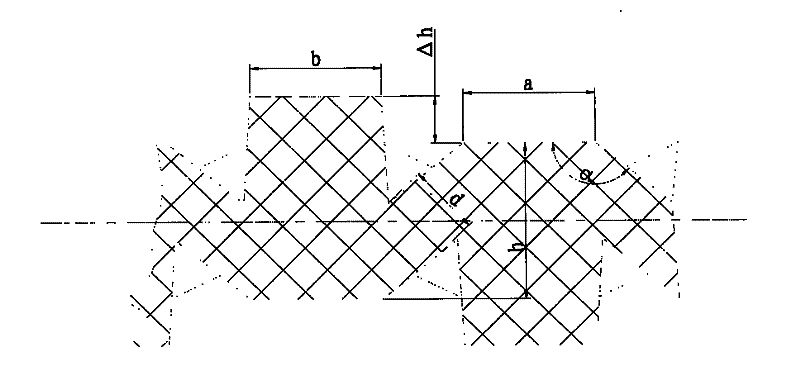

[0021] Please see figure 2 , is a partial enlarged view of the section view. The upper surface of the solid prism b is higher than the upper surface of the hollow prism a, and its height difference is Δh. Changing the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com