FPD assembly assembling device

A technology for assembling devices and components, which is used in identification devices, assembling printed circuits and electrical components with electrical components, etc., can solve the problems of reduced production efficiency, increased transportation volume, and hindered shortening of manufacturing tact time, and achieves miniaturization and reduction. The effect of small conveying volume and shortening conveying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

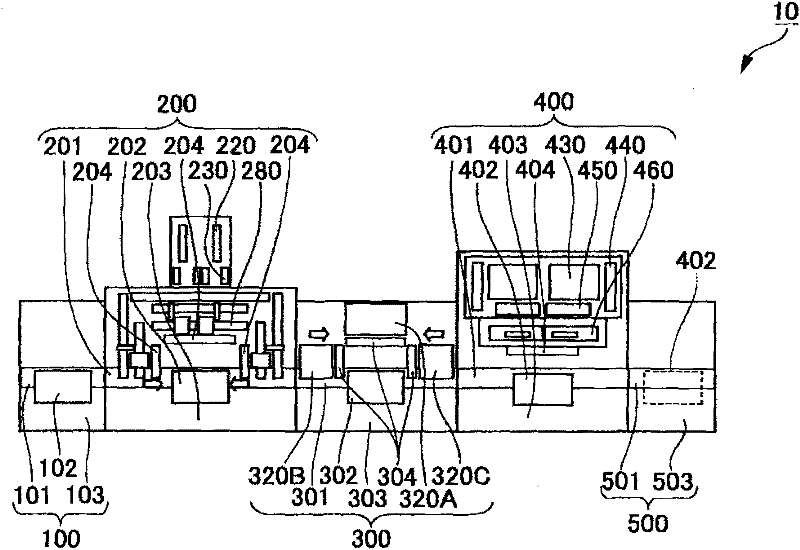

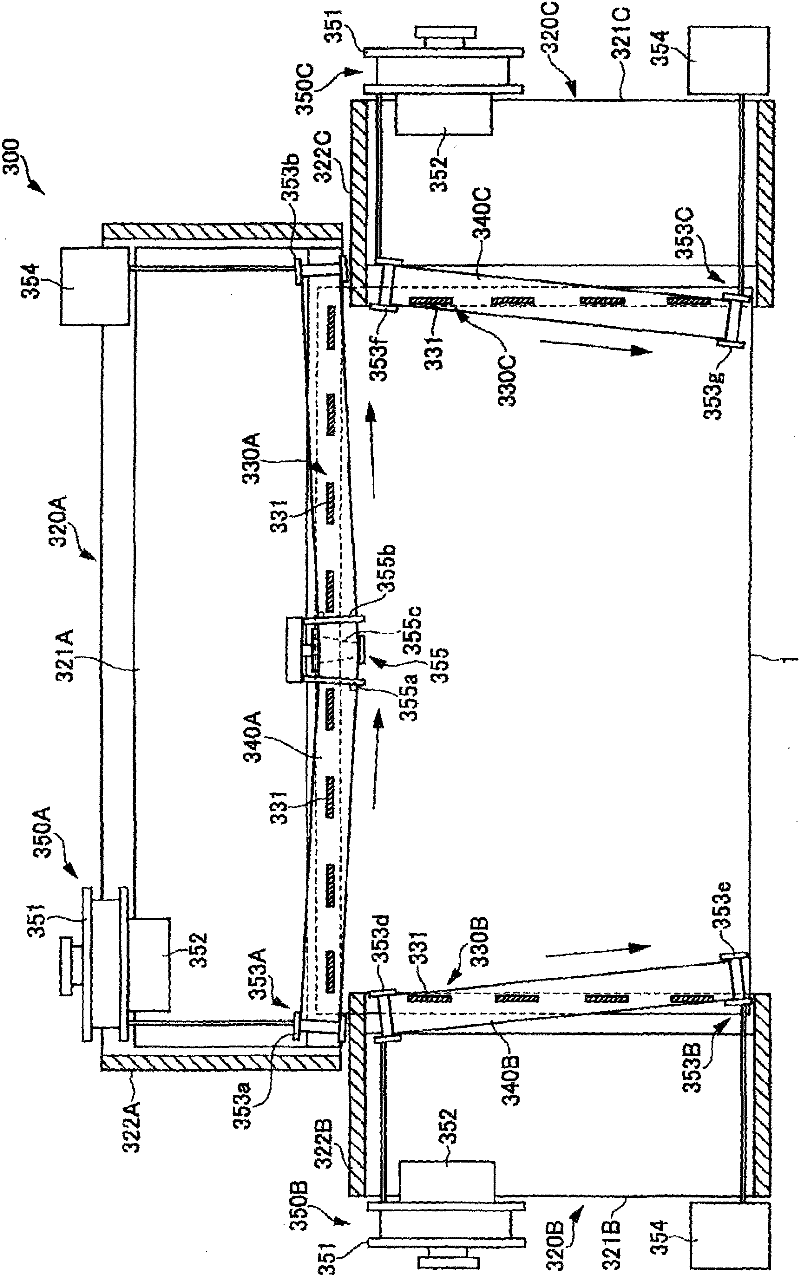

[0034] Below, refer to Figure 1 to Figure 5 An embodiment of a mounting apparatus for implementing an FPD (Flat Panel Display) module will be described. In addition, in each figure, the same code|symbol is attached|subjected to the common member.

[0035] (FPD components)

[0036] First, refer to figure 1 Describes FPD components.

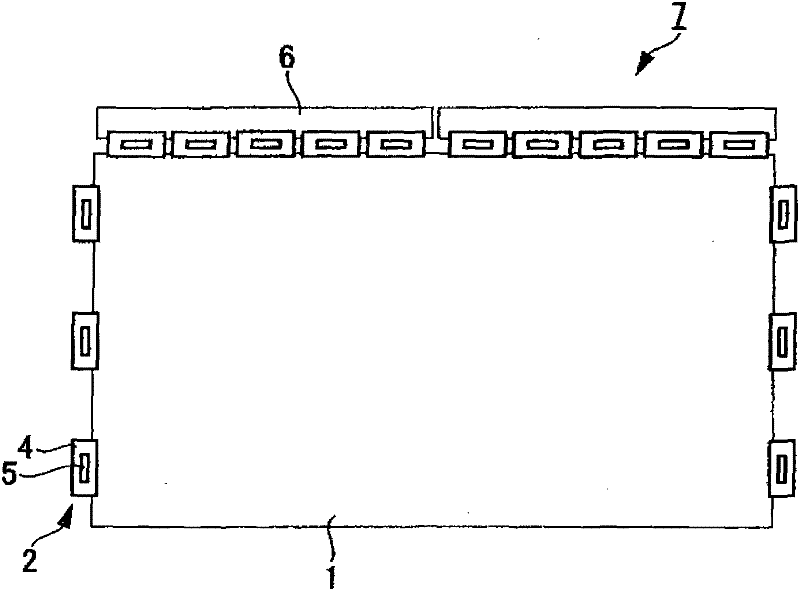

[0037] figure 1 It is a top view showing the schematic structure of the FPD module which is mounted and mounted by this invention.

[0038] like figure 1As shown, the FPD module 7 is configured such that a plurality of mounting members 2 are connected to the peripheral edge portion of the display substrate 1 by ACF bonding, and a PCB 6 is ACF-connected to a part of the mounting members 2 . The mounting member 2 is an electronic component in which an IC chip 5 is mounted on an FPC (Flexible Printed Circuit) 4 formed by applying a printed circuit (not shown) of copper foil on a flat rectangular polyimide film. of. The IC chip 5 is mounted su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap