Braking system with electric brake booster

一种伺服制动器、制动系统的技术,应用在制动器、制动传动装置、运输和包装等方向,能够解决制动系统安装复杂、直径大、昂贵等问题,达到尺寸体积小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

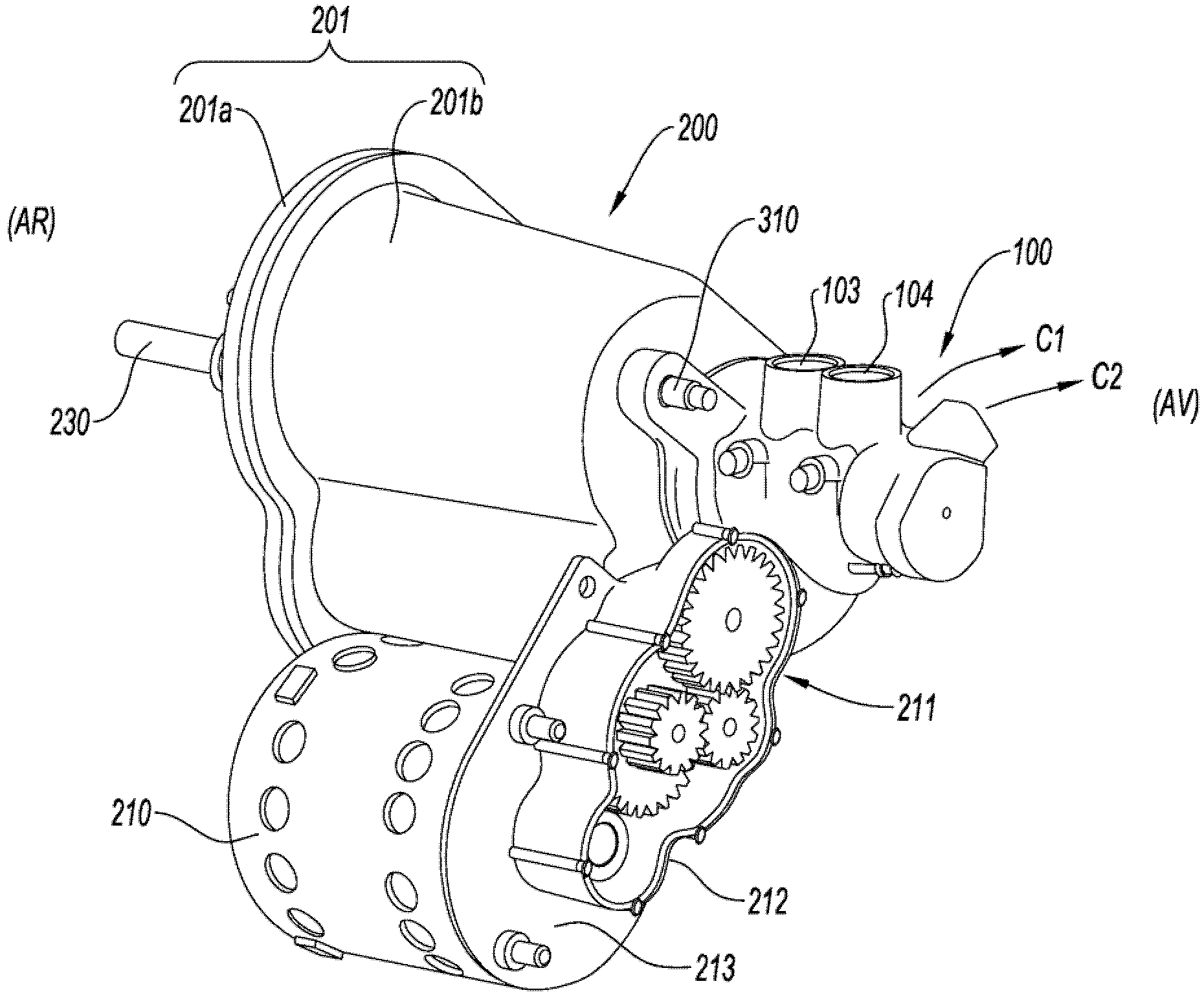

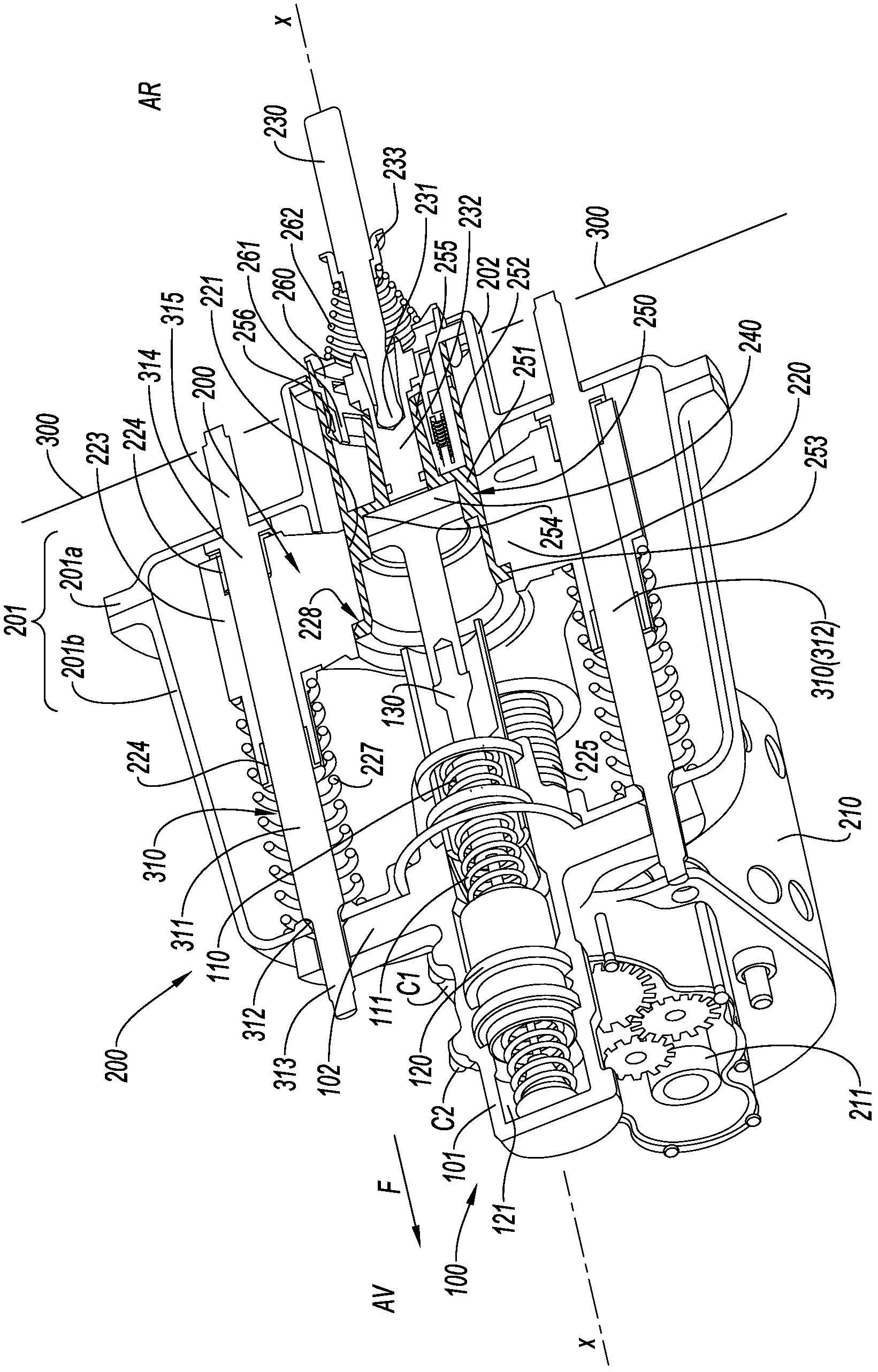

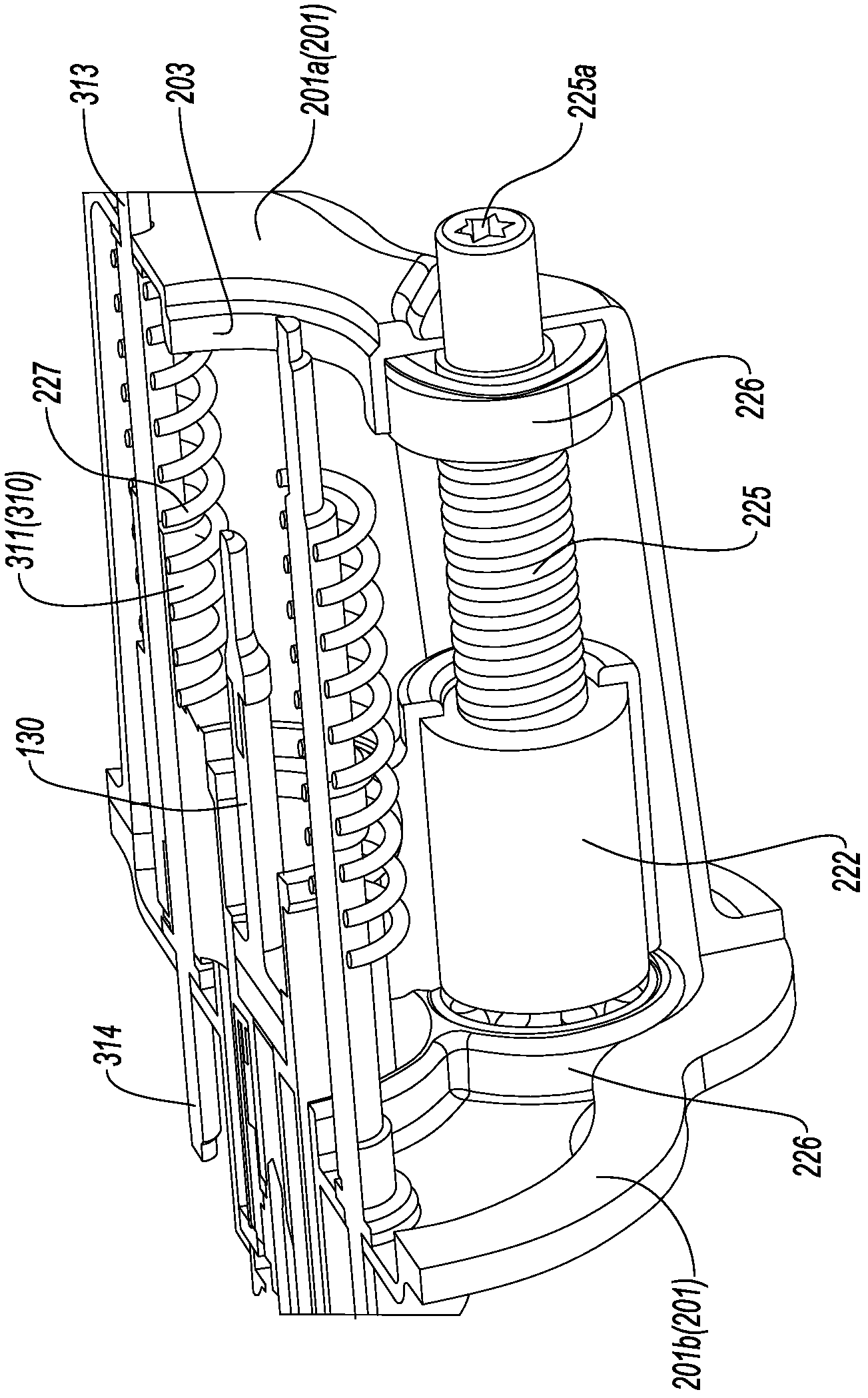

[0027] according to figure 1 and figure 2 , the brake system with a master cylinder assisted by an electric servo brake includes a master cylinder 100, the master cylinder is connected with an electric servo brake 200, the electric servo brake is equipped with an actuator, and the actuator is driven by an electric motor 210 It consists of a reduction gear 211 which controls the translational movement of a transmission piston 220 accommodated in a housing 201 and which acts on the master cylinder 100 in the braking direction (F). The master cylinder 110 is here a tandem master cylinder, the casing 101 of which comprises in its upper part two inlets 103, 104 ( Figure 5 ) to receive the two outlets of the brake fluid reservoir. On this side, two chambers 111 , 121 , one delimited by the primary piston 110 and the other by the secondary piston 120 , are connected to the two brake circuits C1 , C2 . The piston cups (seals) associated with the two pistons and the secondary pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com