Pressing protection strip for stacking solar modules

A technology for solar cell modules and protective strips, applied in special packaging objects, internal frames, packaging of fragile items, etc., can solve the problems of frame scratches and damage, spending a lot of energy, and irregularity, so as to achieve simple placement and exposed parts. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

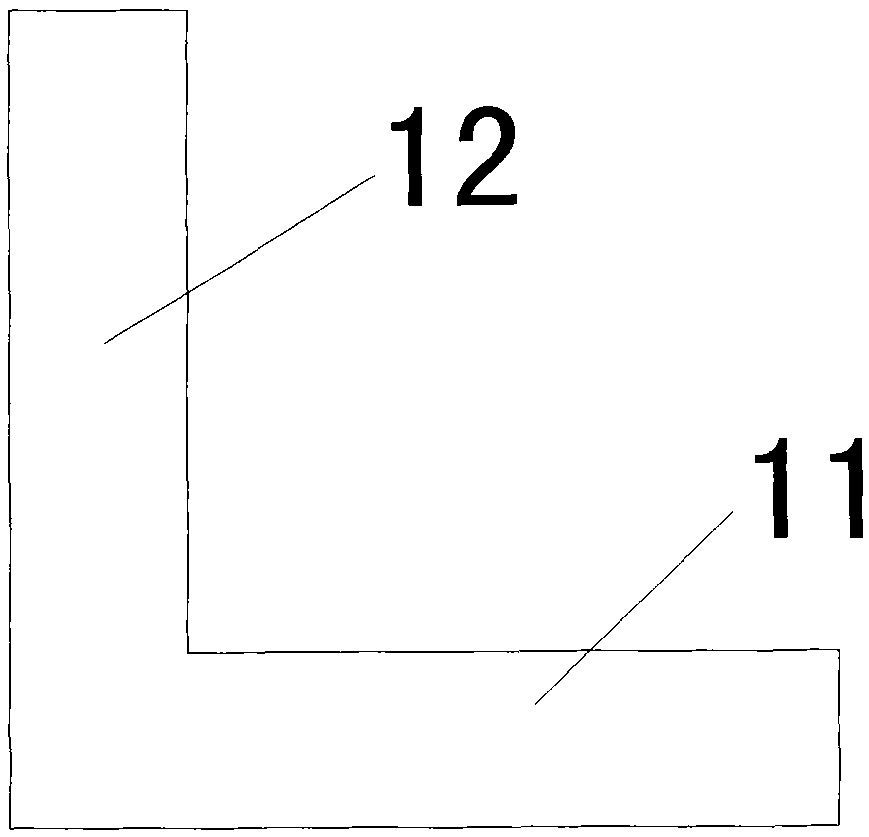

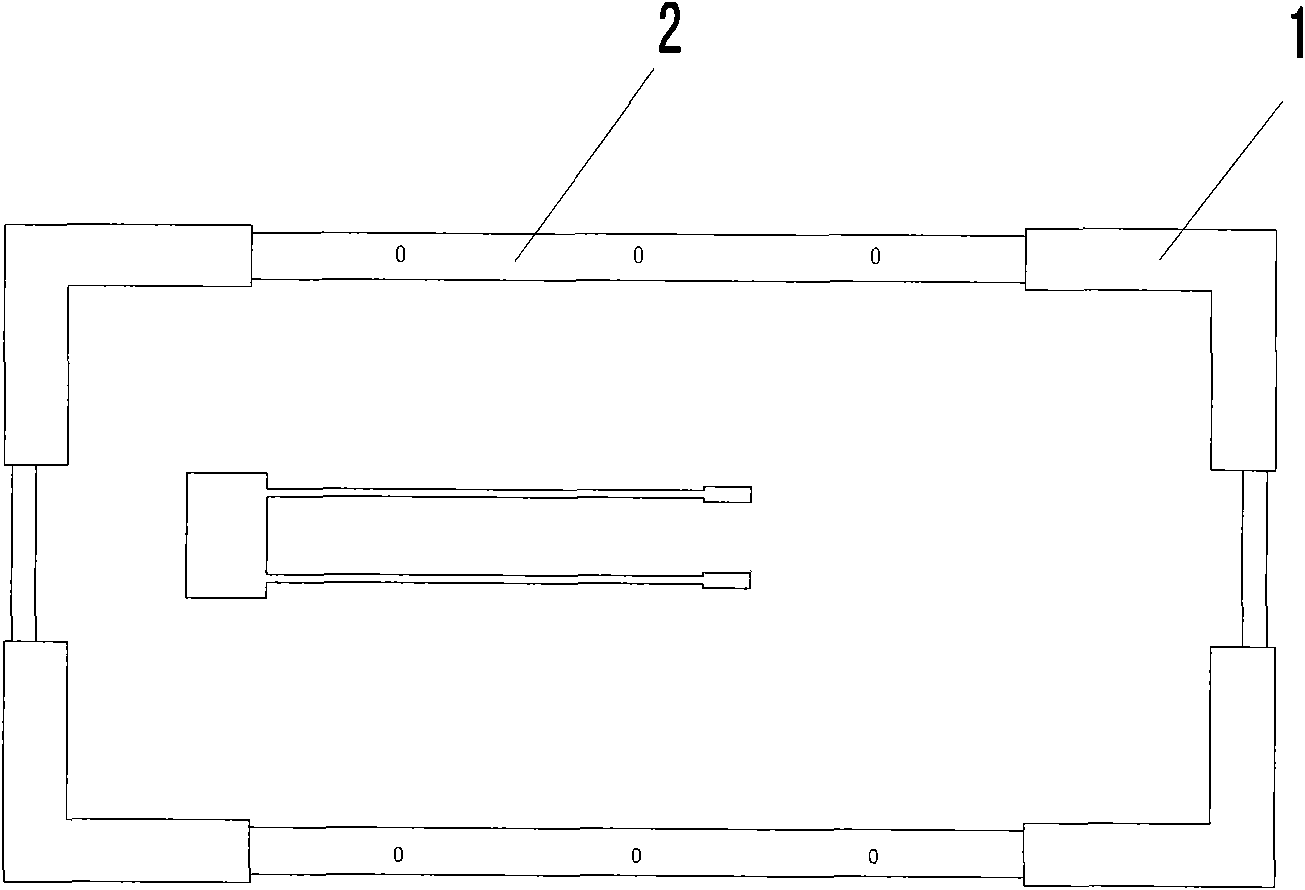

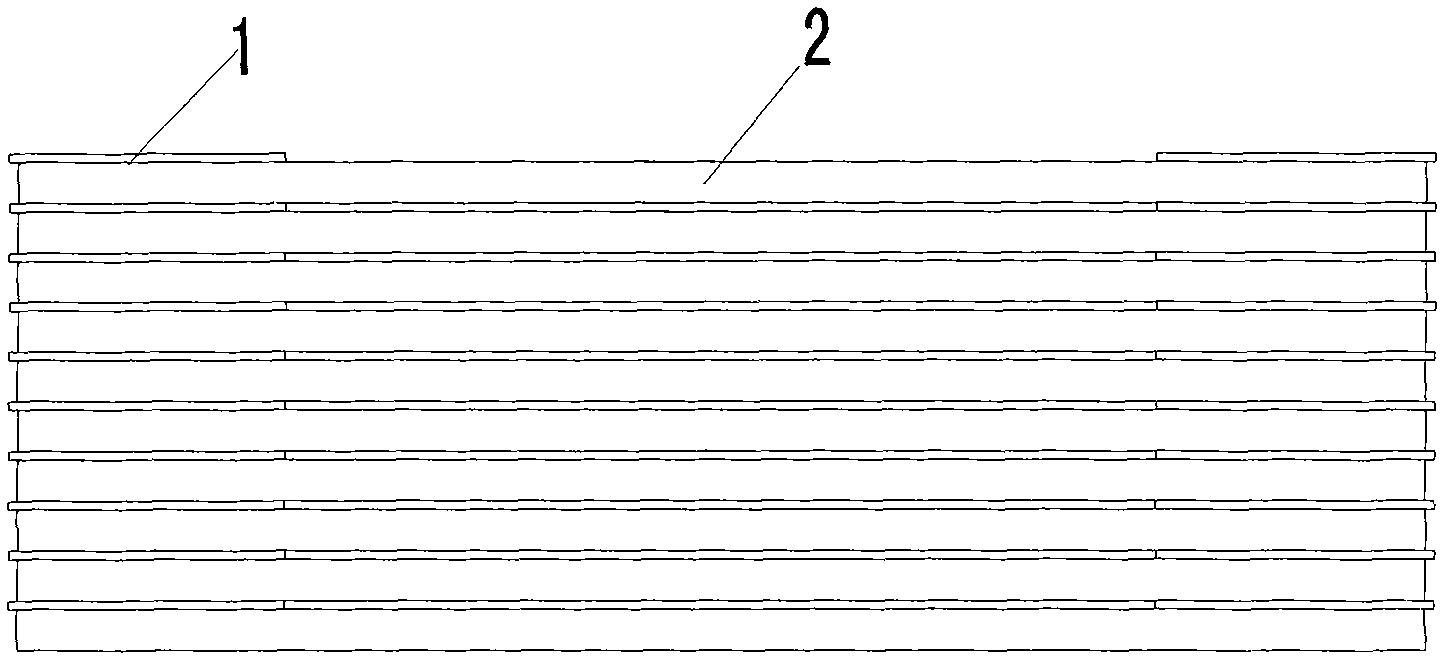

[0011] see figure 1 , the cushion pressure protection strip 1 for stacking solar cell modules of the present invention is a right-angled structural member made of a flexible material, which is selected from one of sponge, rubber, soft plastic, silica gel or foam glue. kind. The pad pressure protection strip includes two right-angled sides 11 and 12 connected into one body, and the length, width and thickness of the two right-angled sides are equal. The length of the two right-angled sides is 200-400mm, the width is 60-100mm, and the thickness is 8-12mm. Generally, the length is 300mm, the width is 80mm, and the thickness is 10mm. This specification is suitable for the stacking of solar cell modules with sizes of 180mm, 220mm and 280mm at the same time.

[0012] The width of the two right-angled sides of the cushion pressure protection strip in the present invention is greater than or equal to the width of the aluminum alloy frame of the solar cell module.

[0013] The use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com