Chemical-mechanical polishing liquid and its application method

A chemical mechanical and polishing liquid technology, applied in polishing compositions containing abrasives, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as high polishing speed, achieve high polishing speed, and accelerate the effect of chemical mechanical polishing

Active Publication Date: 2012-05-23

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because carbon is very stable at room temperature, it is not easy to react chemically, and it has good resistance to mecha

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a chemical-mechanical polishing liquid, which comprises water, a grinding agent and a strong oxidant, the standard electrode potential of which is greater than 0.52V. Added with a strong oxidant, the chemical-mechanical polishing liquid of the invention can obtain a very high polishing speed, so that the chemical-mechanical polishing of carbon element can be accelerated.

Description

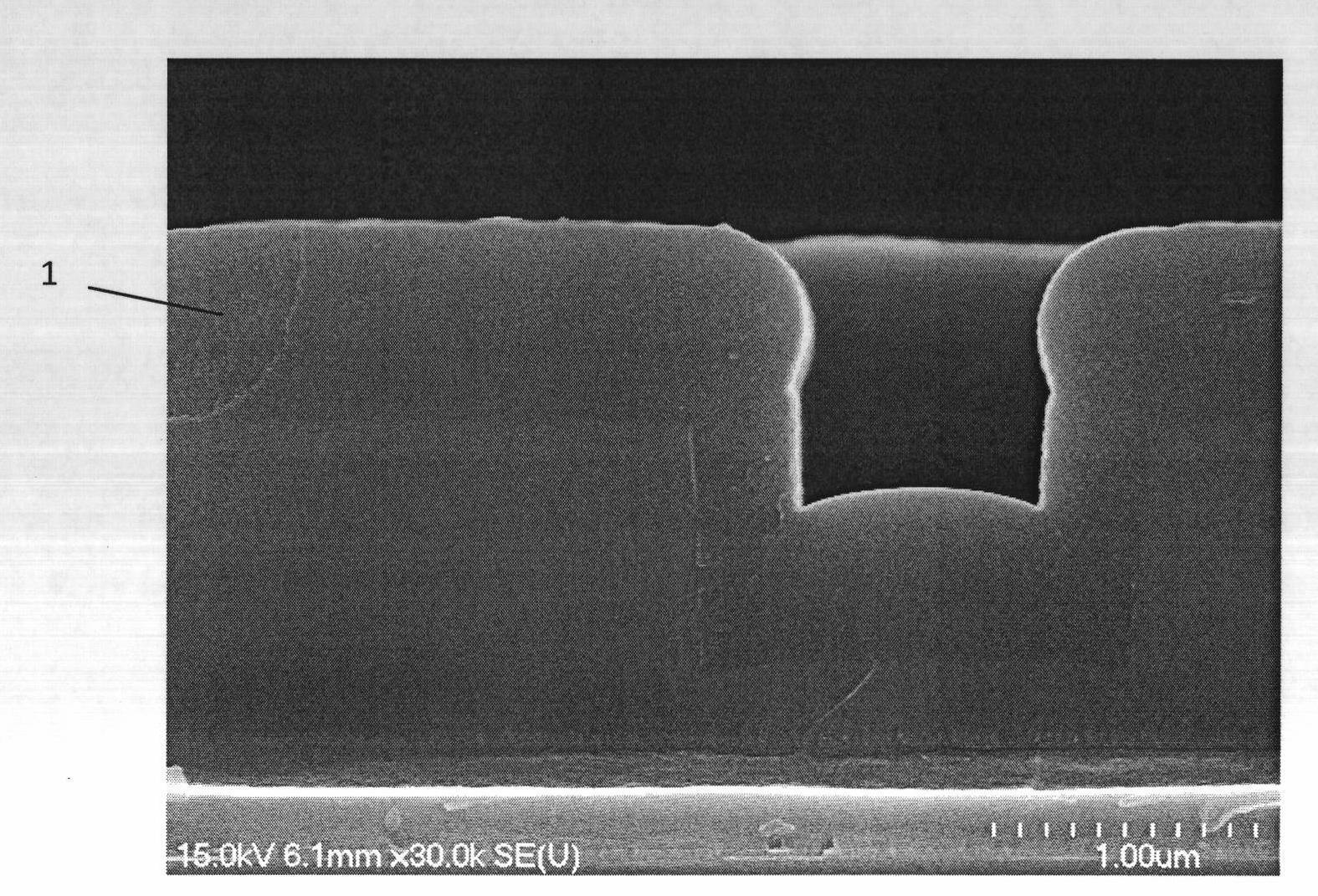

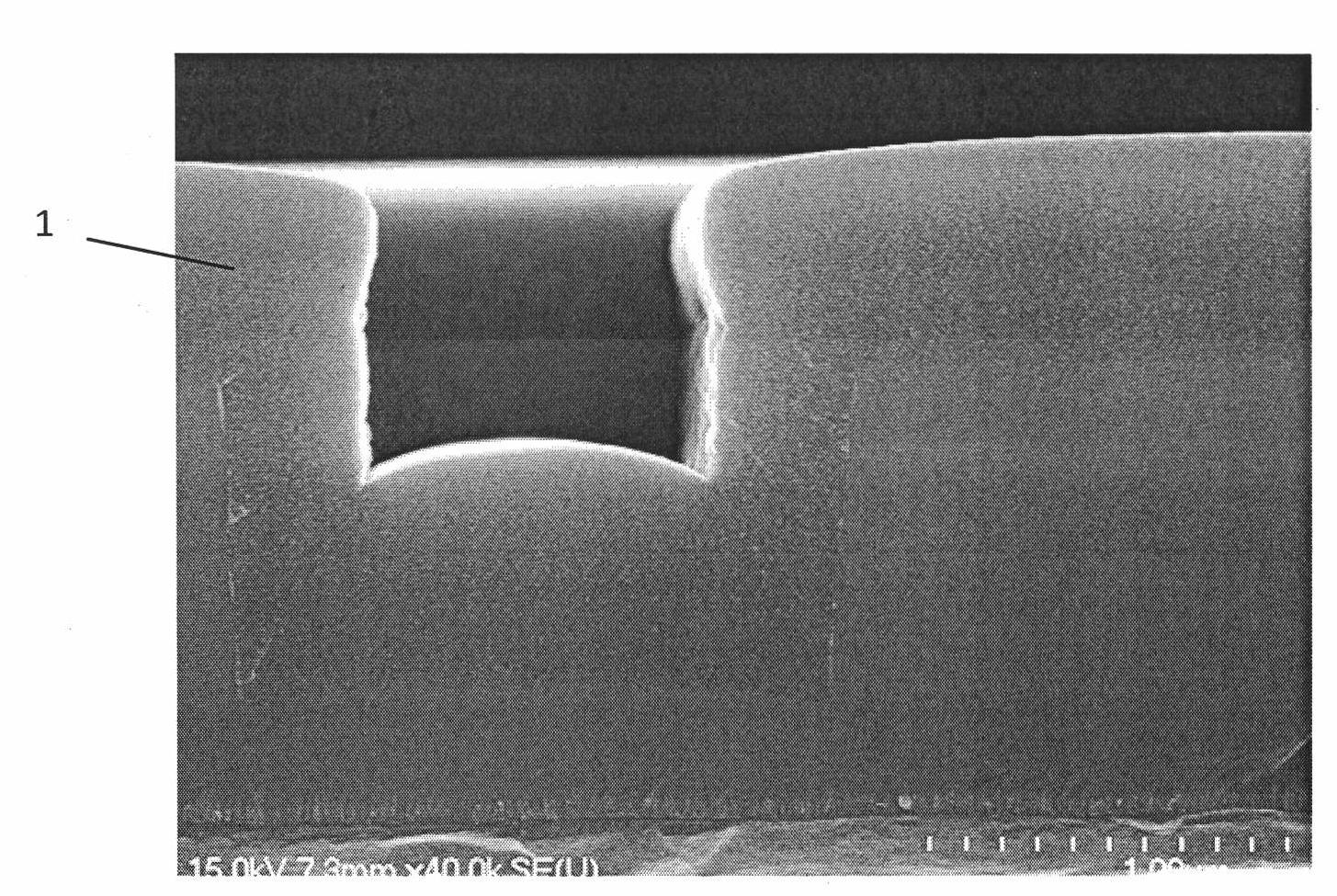

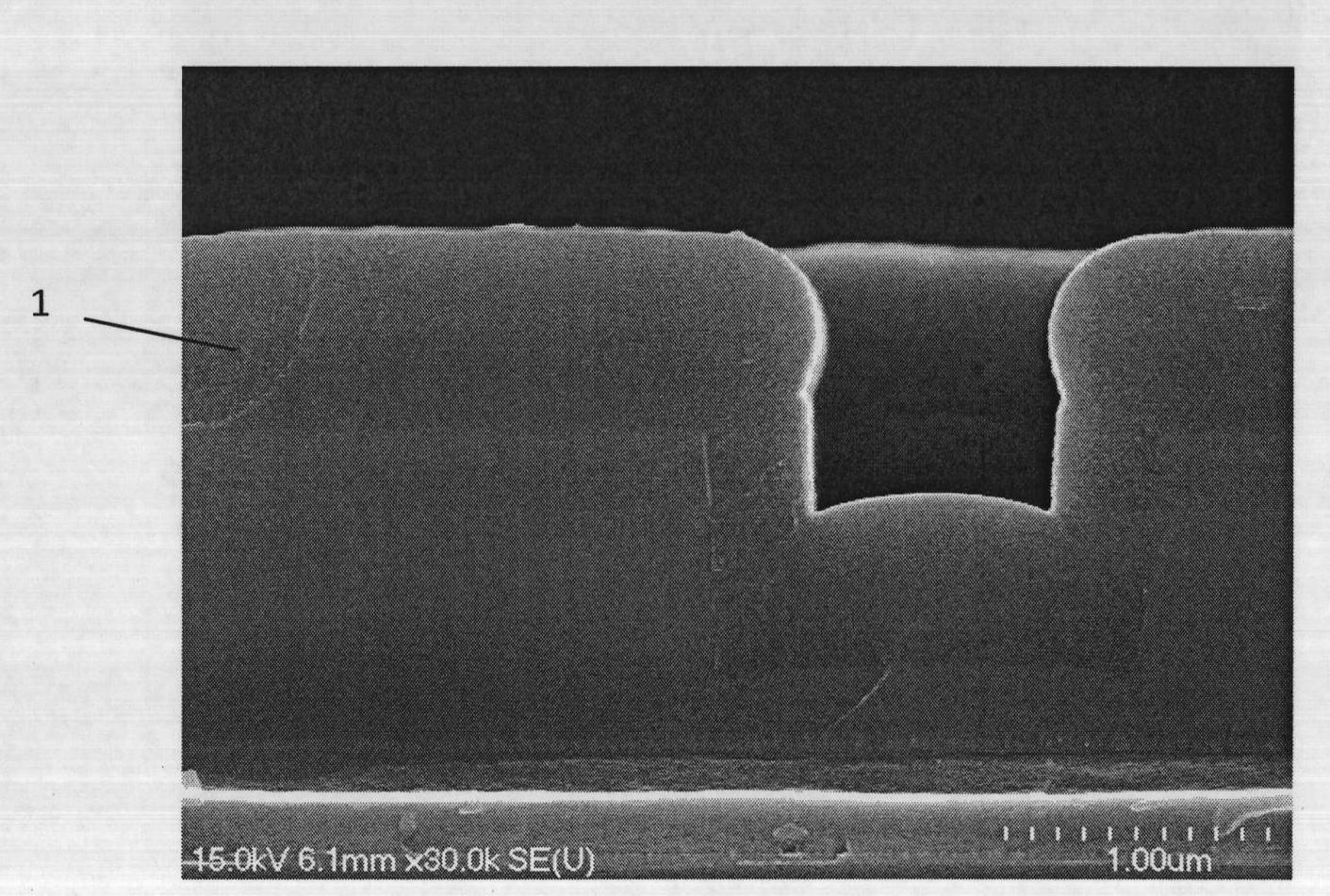

technical field [0001] The invention relates to the field of chemical mechanical polishing, in particular to a chemical mechanical polishing liquid and a using method thereof. Background technique [0002] With the continuous development of semiconductor technology and the continuous increase of interconnection layers in large-scale integrated circuits, the planarization technology of conductive layers and insulating dielectric layers has become particularly critical. In the 1980s, the chemical mechanical polishing (CMP) technology pioneered by IBM is considered to be the most effective method for global planarization. [0003] Chemical Mechanical Polishing (CMP) consists of chemical action, mechanical action, and a combination of both. It usually consists of a grinding table with a polishing pad, and a grinding head for carrying chips. The grinding head holds the chip and presses the front side of the chip against the polishing pad. When chemical mechanical polishing is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09G1/02H01L21/306

Inventor 王晨何华锋

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com