Slip clamping type sucker rod blowout preventer

A technology of sucker rod and blowout preventer, which is applied in the direction of drill pipe, drilling equipment, wellbore/well parts, etc., can solve the problems of polluting the environment, affecting the blowout preventer to seal the wellhead, and damage to the surface of the sucker rod to achieve structural Reasonable, improve safety and reliability, prevent the effect of running up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

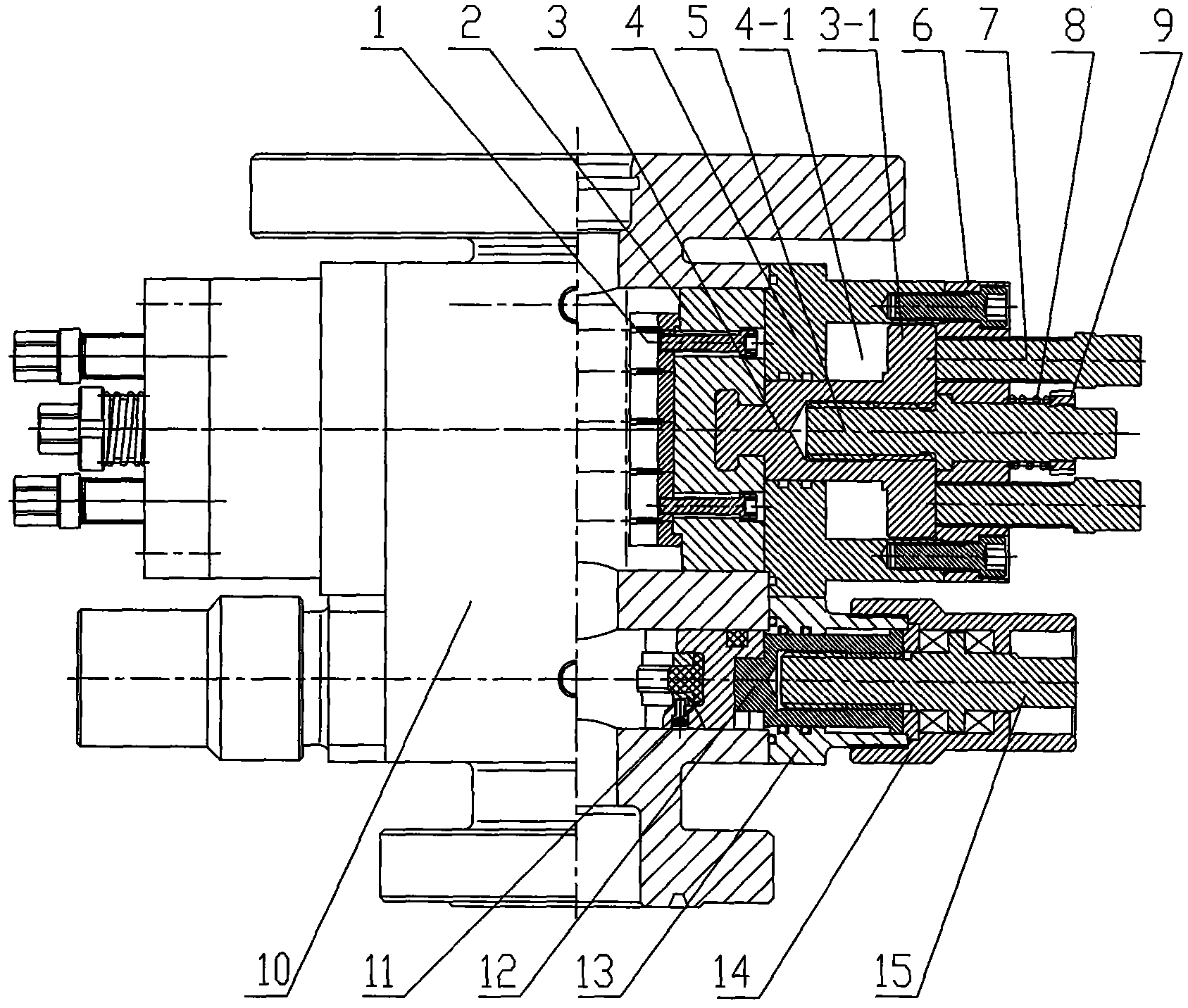

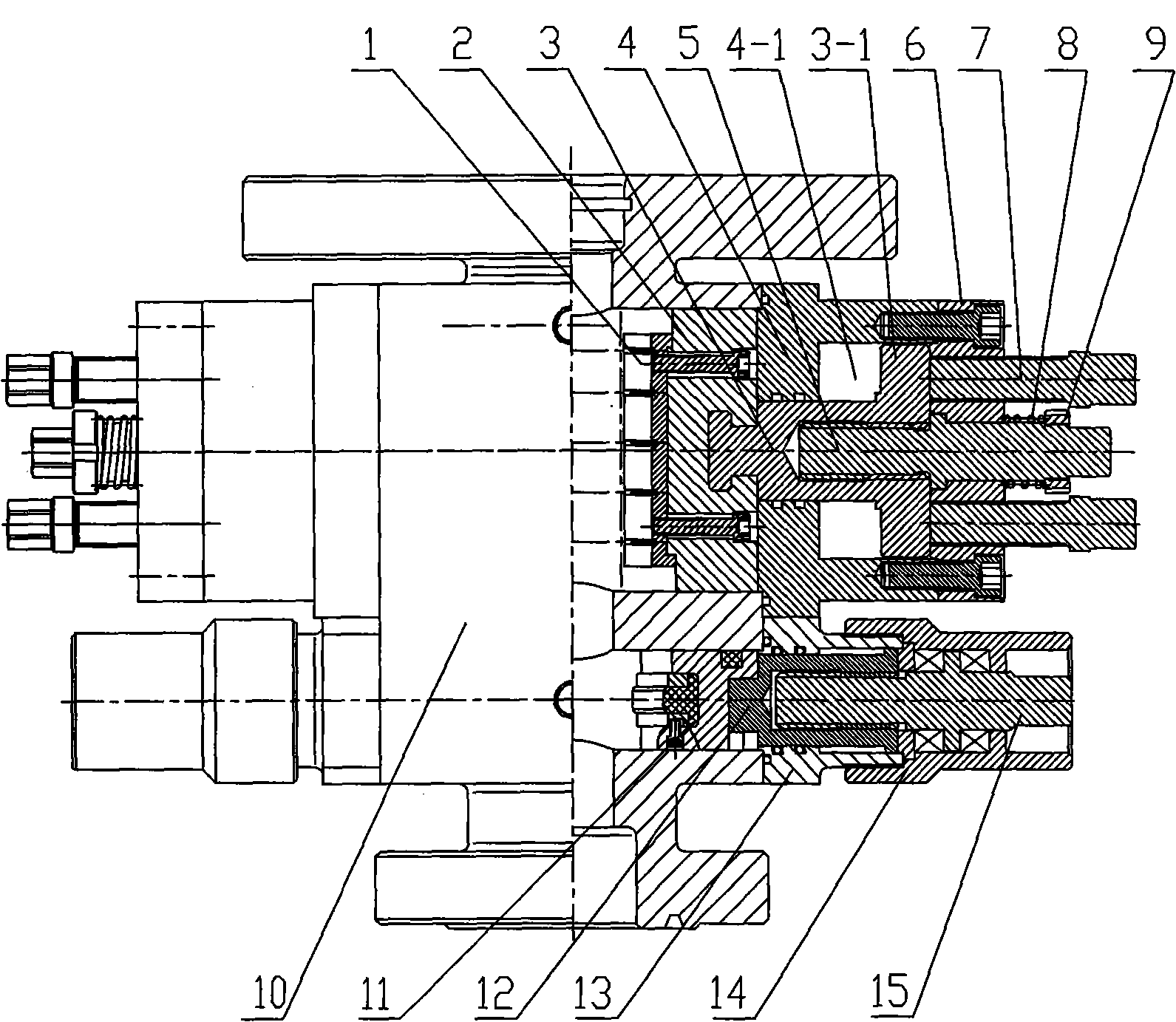

[0011] The slip clamping type sucker rod blowout preventer of the present invention is based on the existing single ram sucker rod blowout preventer, and a slip locking assembly is added. Such as figure 1 As shown, the single ram sucker rod blowout preventer includes a body 10 and a half-sealed ram assembly; the main diameter of the body 10 is symmetrically provided with a half-sealed ram cavity. The half-sealed ram assembly includes a half-sealed ram 11, a half-sealed tightening shaft 12, a half-sealed side door 13, a half-sealed gland 14 and a half-sealed tightening lead screw 15; In the cavity of the half-sealed ram, a half-sealed side door 13 and a half-sealed gland 14 are sequentially installed outside the cavity of the half-sealed ram; Link to each other with half locking lead screw 15. The slip locking assembly includes slip 1, slip seat 2, sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com