Waterway switch valve group and shower head using same

A waterway switching and valve group technology, which is applied to cocks, multi-way valves, valve devices and other directions including cut-off devices. Feature-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

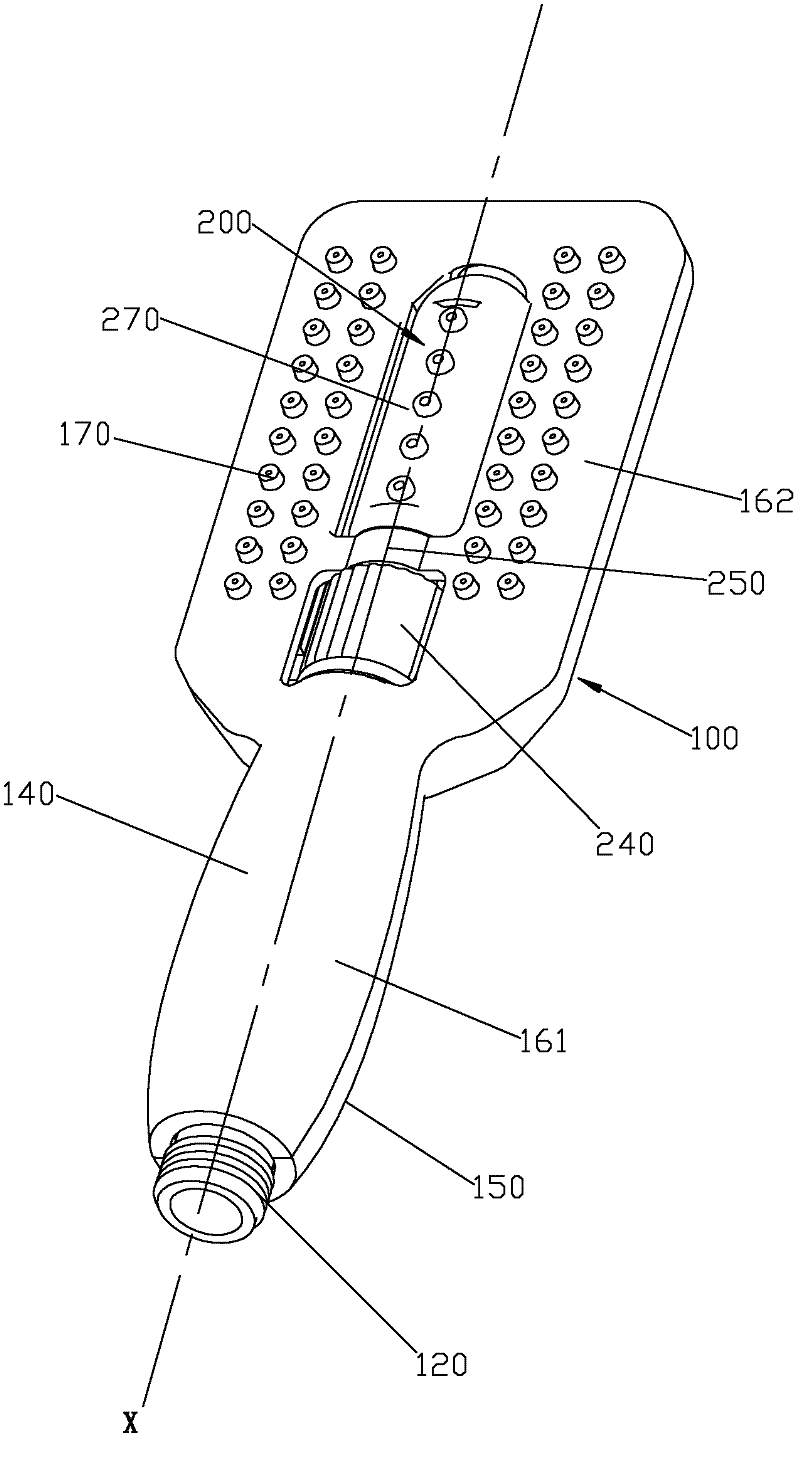

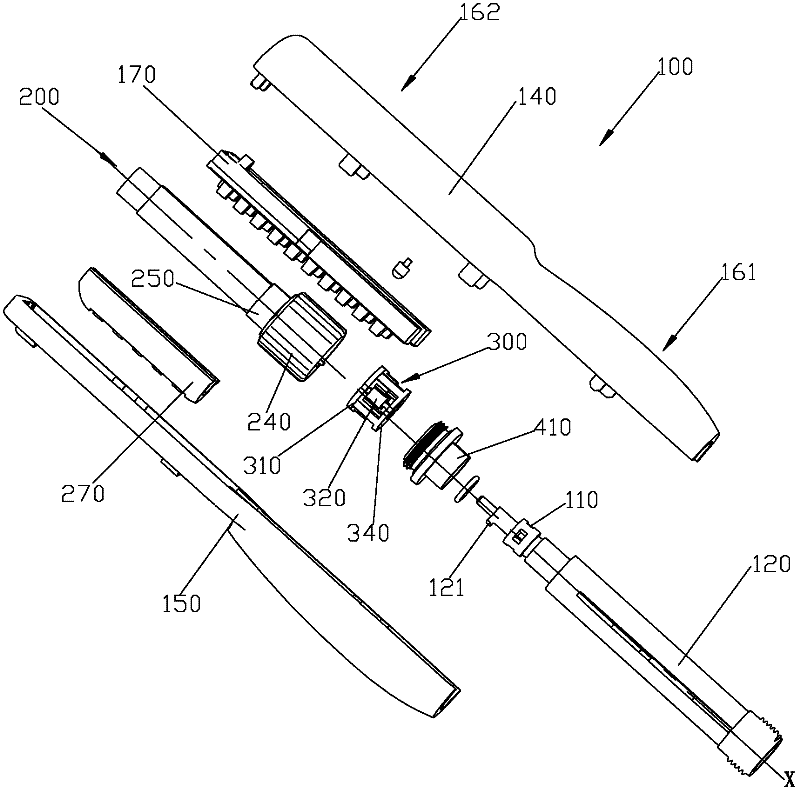

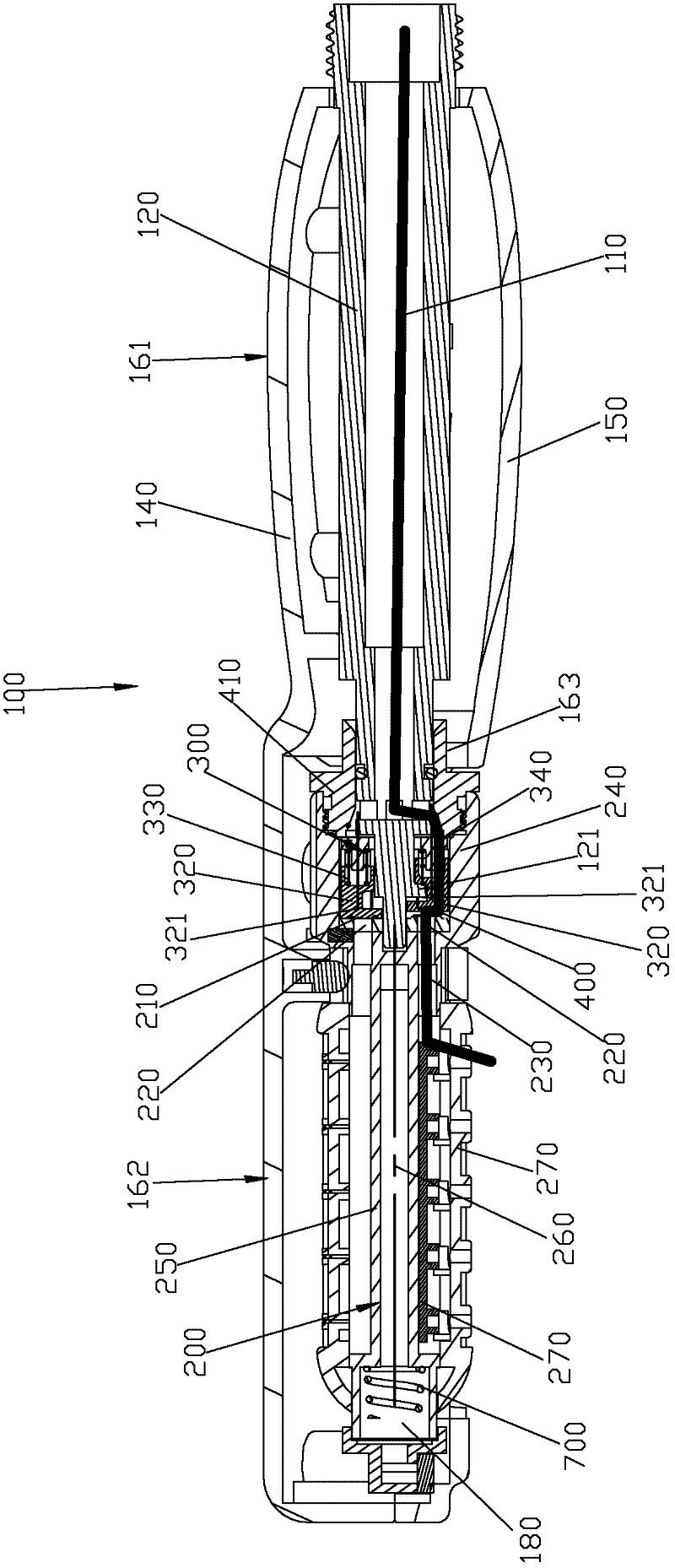

[0051] Please check Figure 1 to Figure 10 , a shower using a waterway switching valve group, which includes a fixed unit 100 and a rotating unit.

[0052] The fixing unit 100 is provided with a water inlet channel 110 and a first water outlet channel 130 .

[0053]In this embodiment, the fixing unit 100 includes a body and a central axis 120 . The central axis 120 is provided with a hollow hole, which is formed by a concave setting on the head end surface of the central axis 120. The central axis 120 is also provided with a radial hole that runs through the inside and outside, and the inner port of the radial hole is connected to the hollow hole. For the part close to the bottom of the hollow hole, the outer port is set at the tail end of the central axis 120 . In this embodiment, the hollow hole and the radial hole are connected to form the water inlet channel 110 .

[0054] In this embodiment, the body is divided into a handle section 161 and an annular section 162, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com