Tubular glass vacuum tube in scale-free anti-explosion tube

A technology of glass vacuum tubes and explosion-proof tubes, which is applied to solar collectors, solar thermal devices, lighting and heating equipment that use working fluids, and can solve problems such as easy bursting, and achieve fast thermal start, high energy efficiency, and smooth flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

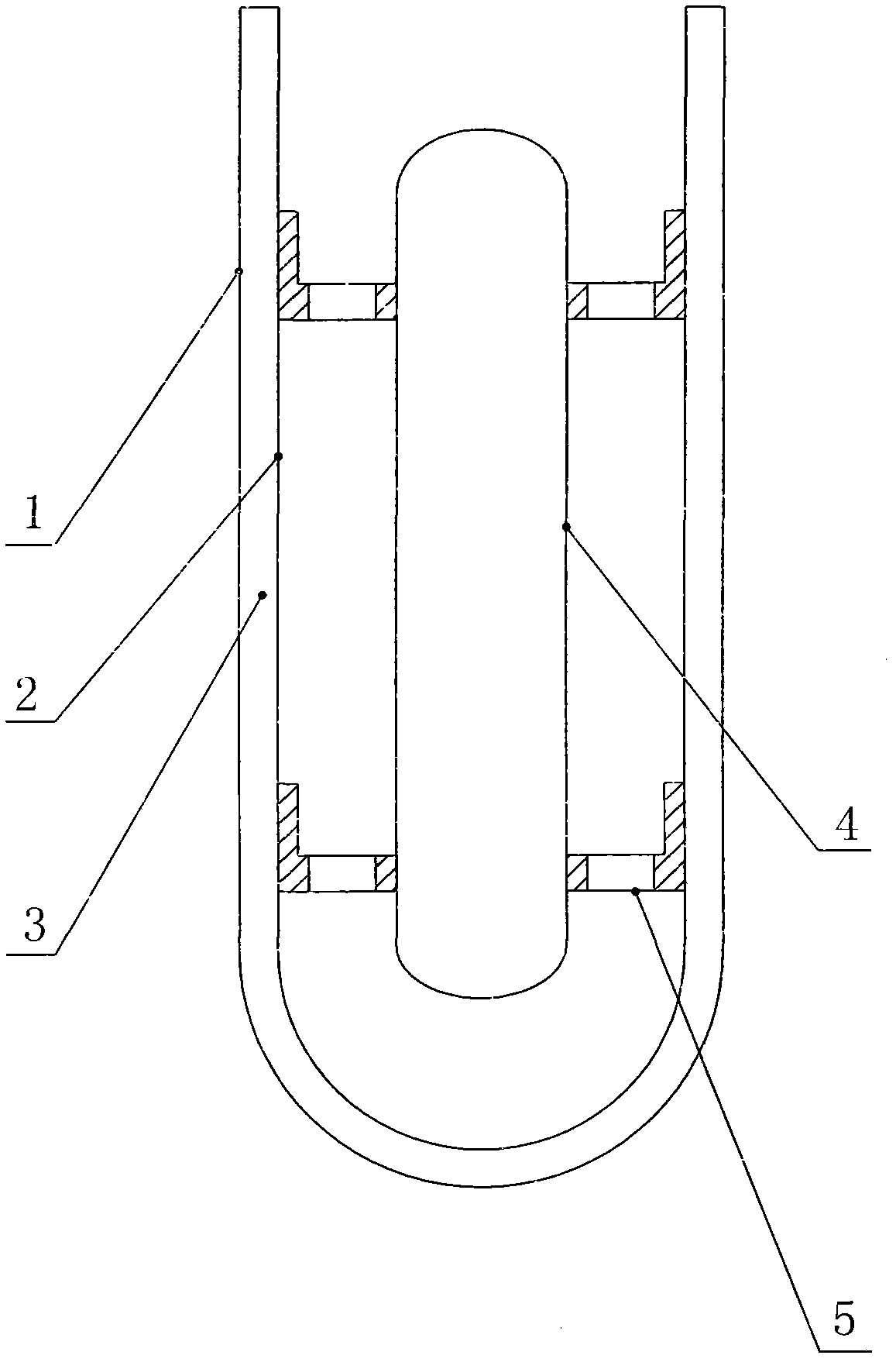

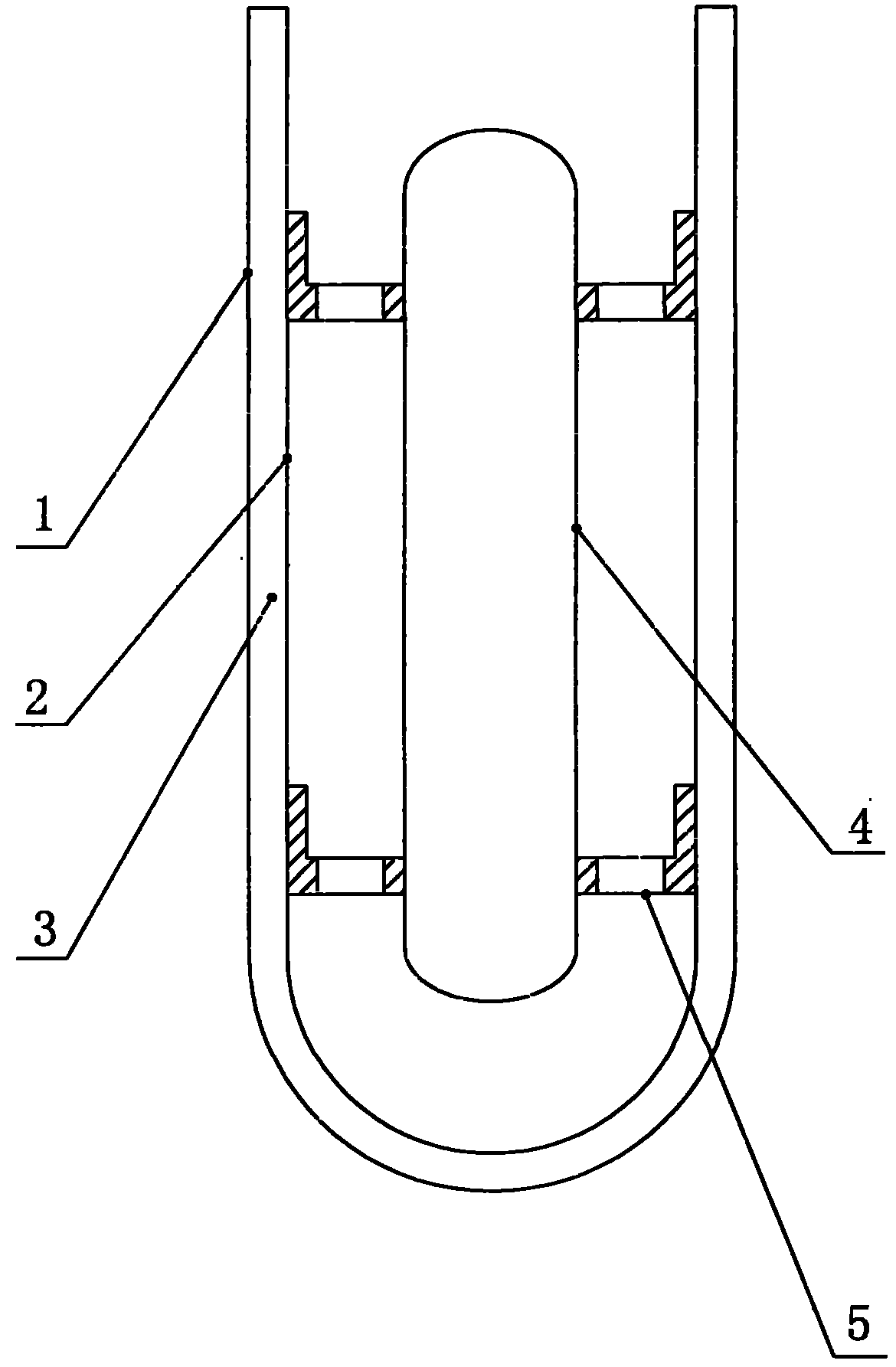

[0010] exist figure 1 In the non-scaling explosion-proof tube, the tubular glass vacuum tube includes an inner glass tube 2 and an outer glass tube 1. There is a low-pressure vacuum layer 3 between the outer glass tube 1 and the inner glass tube 2. The outer surface of the inner glass tube 2 is coated with heat-absorbing One end of the inner glass tube 2 and the outer glass tube 1 is respectively sealed to form a free end, the other end of the inner glass tube 2 and the outer glass tube 1 is sealed to form an open end, and a hollow glass core 4 is arranged in the inner glass tube 2 , the distances between the cavity glass core 4 and the open end and the free end are not less than five centimeters, and a support frame 5 is provided between both ends of the cavity glass core 4 and the inner glass tube 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com