Method for correcting thermophysical parameters and absorptivity of material

A technology of thermophysical parameters and correction methods, applied in the direction of material thermal development, etc., can solve the problems of complex and inapplicable measuring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

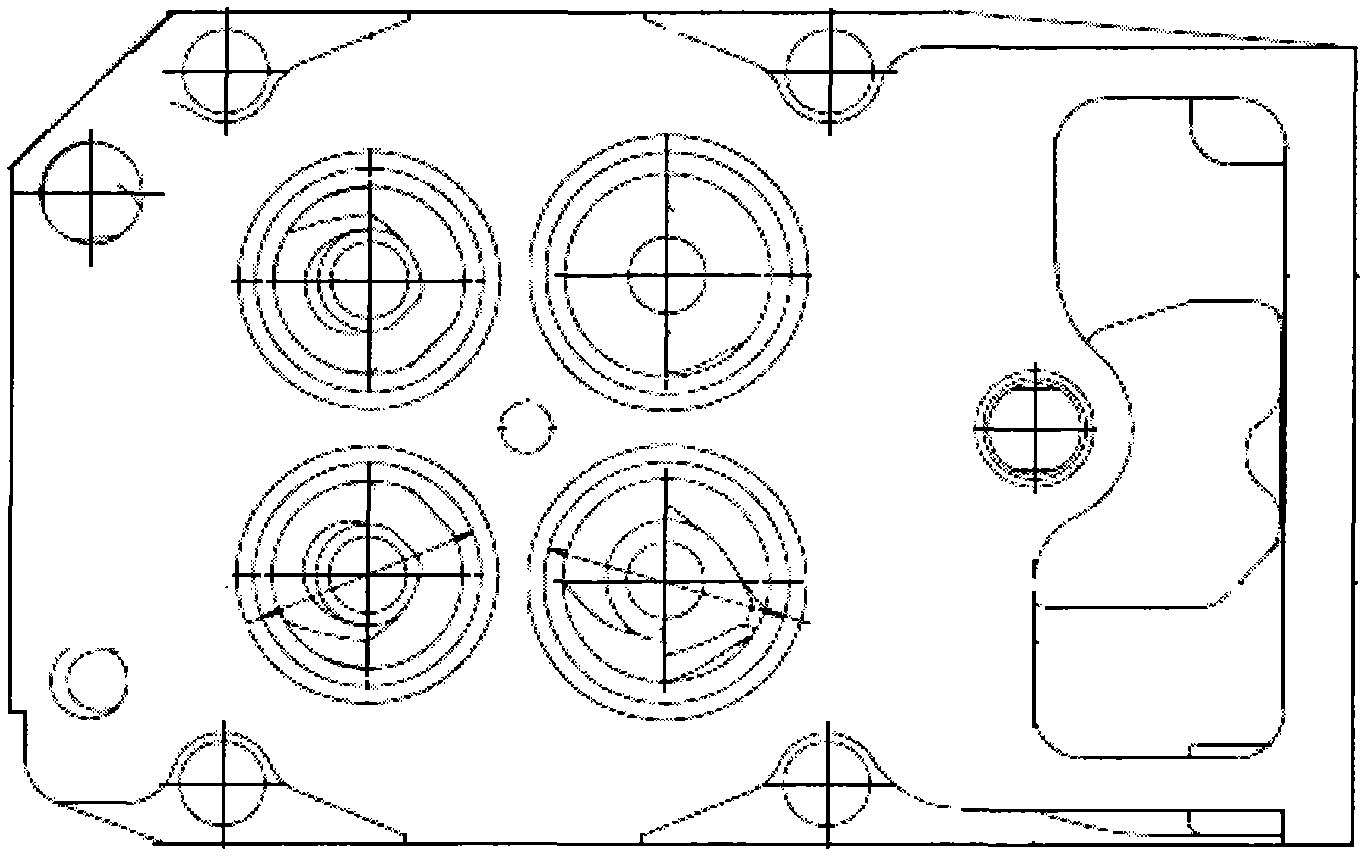

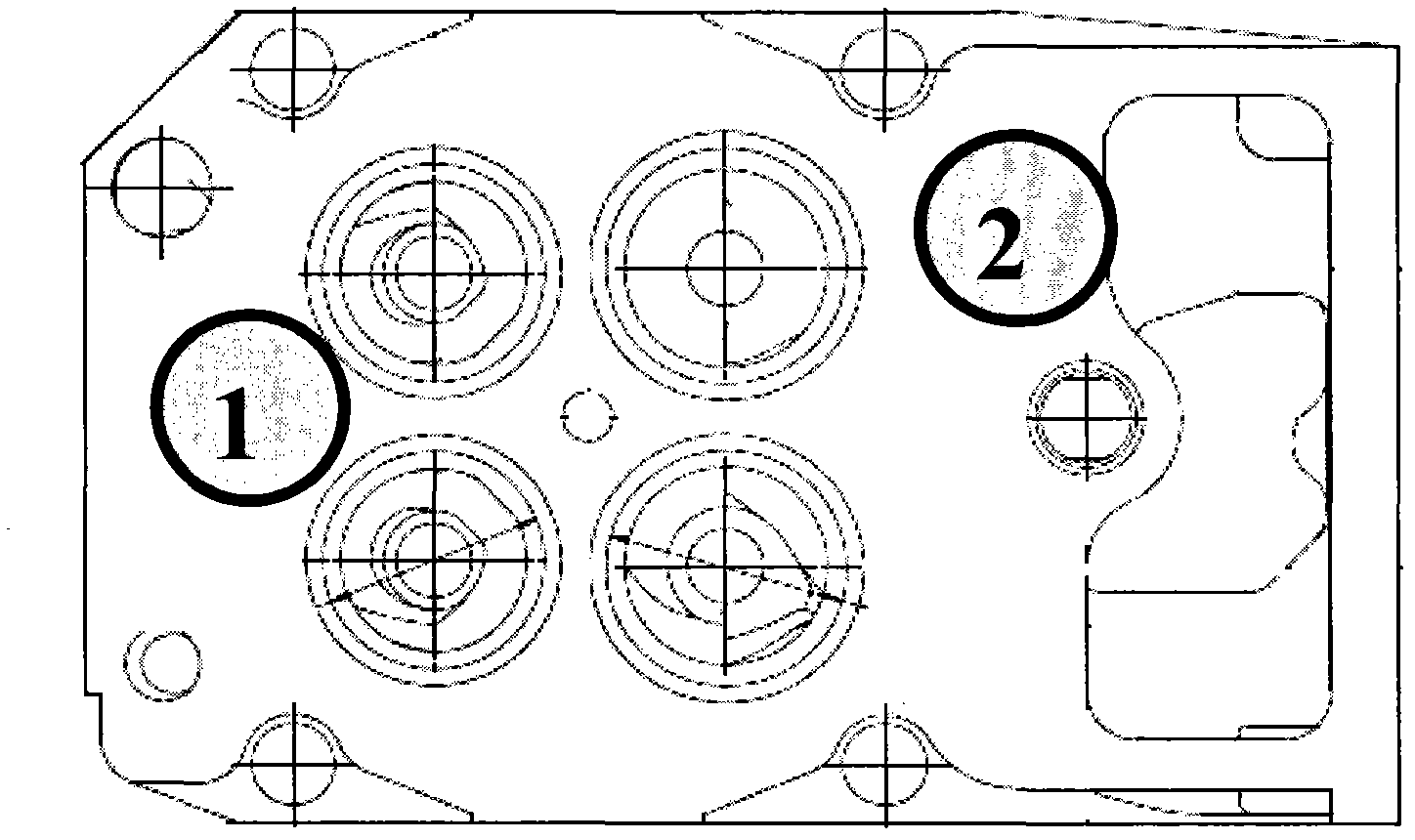

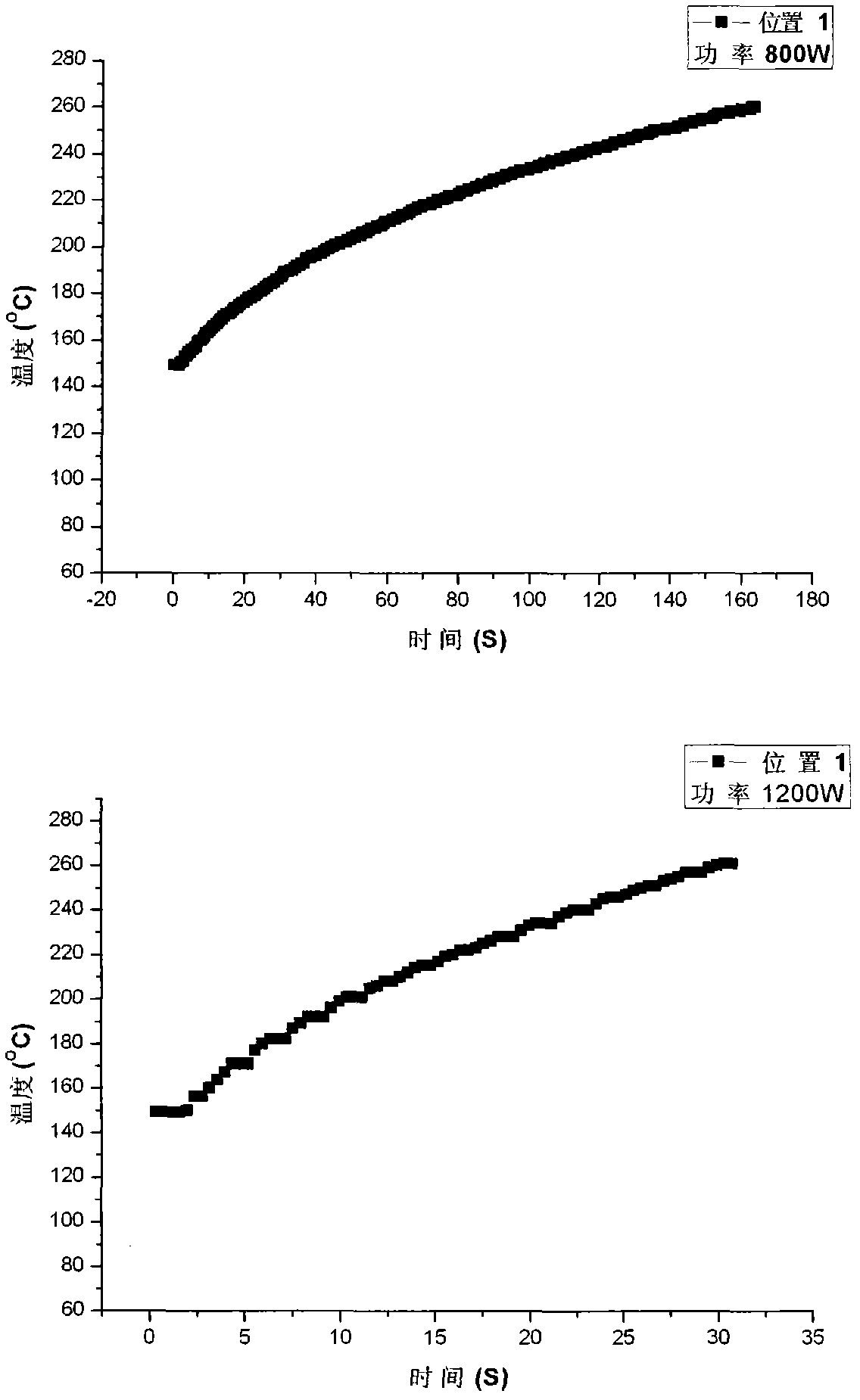

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The present invention provides a correction method for the thermal physical parameters and absorption rate of materials used in the cylinder head or piston laser thermal load test, which mainly adopts the combination of experiment and simulation calculation. Methods.

[0034] 1. Determine the materials and basic laser beam parameters required for experiments and simulation calculations

[0035] 2. Calibration:

[0036] 1. Adjust the angle of the laser head so that the beam can act vertically on the surface of the cylinder head or piston. And test the initial cylinder head temperature.

[0037] 2. Calibration test

[0038] The correction test includes three parts: small spot correction experiment, simulation calculation, and large spot correction test that completely covers the fire surface.

[0039] 1) Small spot correction test: In the small s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap