Pressure switch

A pressure switch and pressure chamber technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems affecting the sensitivity of the switch and the precision of the return diaphragm, so as to improve the precision and sensitivity, high precision of the switch, and structure Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

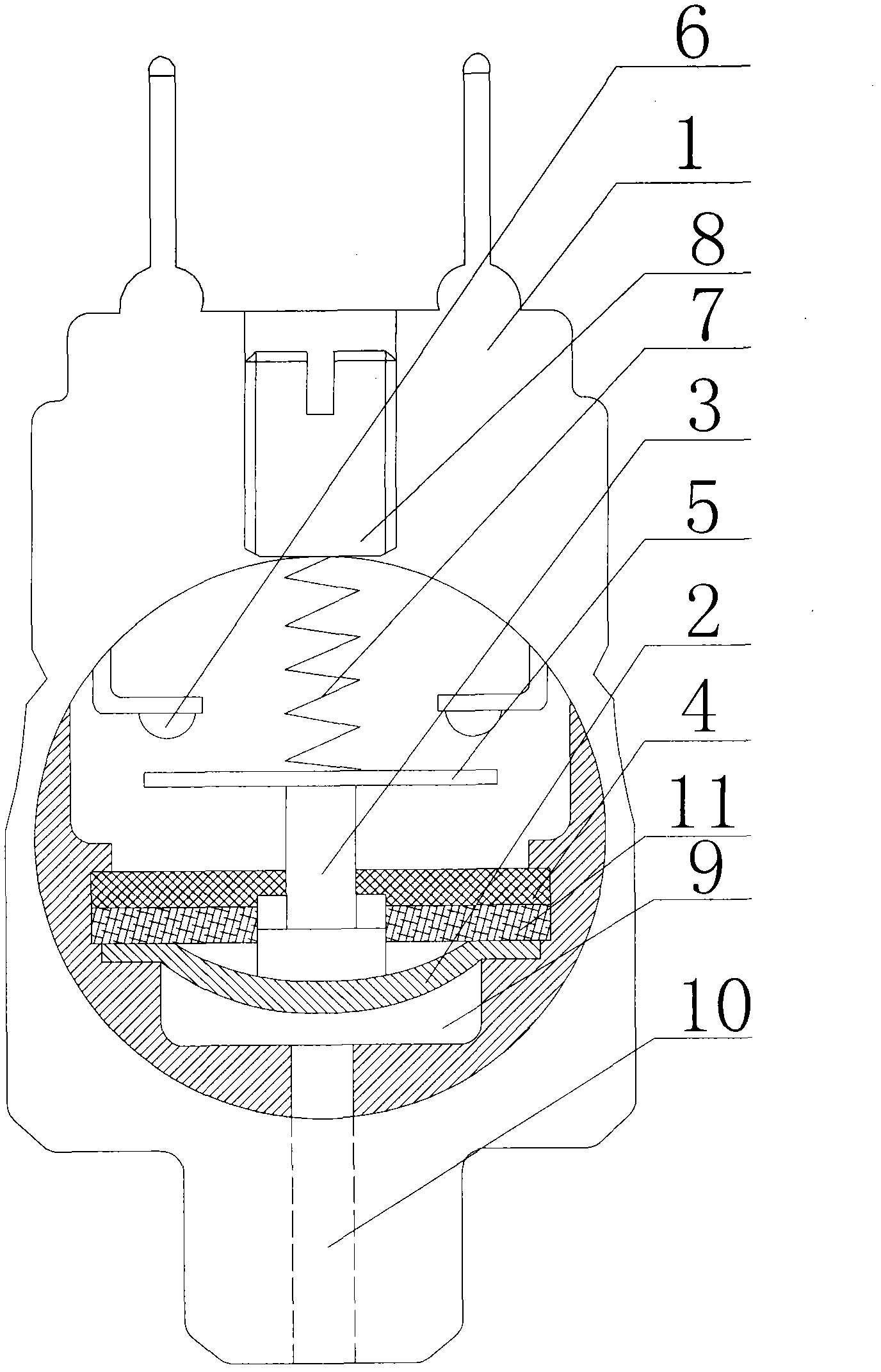

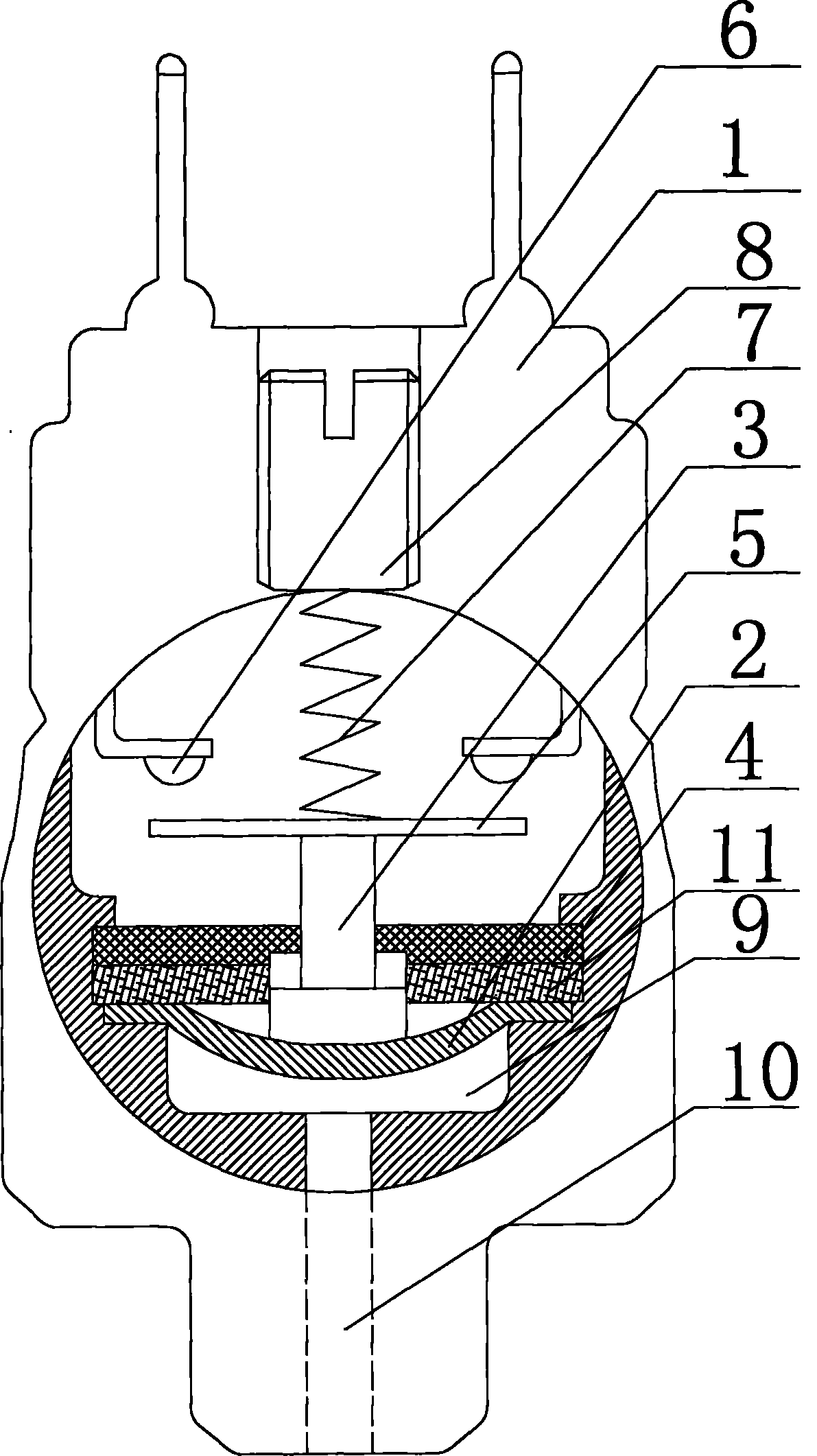

[0013] Such as figure 1 As shown, a pressure switch includes a housing 1, a return diaphragm 2, a ceramic push rod 3, a baffle plate 4, a connecting piece 5 and a connecting contact 6, and the returning diaphragm 2 is placed in the housing 1 , the top of the ceramic mandrel 3 passes through the baffle plate 4 and is connected to the connecting piece 5, the bottom of the ceramic mandrel 3 is in contact with the return diaphragm 2, and the top of the connecting piece 5 is provided with a return spring 7, which passes through the The adjusting screw 8 is fixed in the housing 1, the connecting contact 6 is placed above the connecting piece 5 and there is a gap between the connecting piece 5, and a closed pressure chamber is formed between the return diaphragm 2 and the housing 1 9. A pressure channel 10 communicating with the pressure chamber 9 is provided at the bottom of the housing 1. In order to improve the accuracy and sensitivity of the return diaphragm 2, the baffle 4 is fo...

Embodiment 2

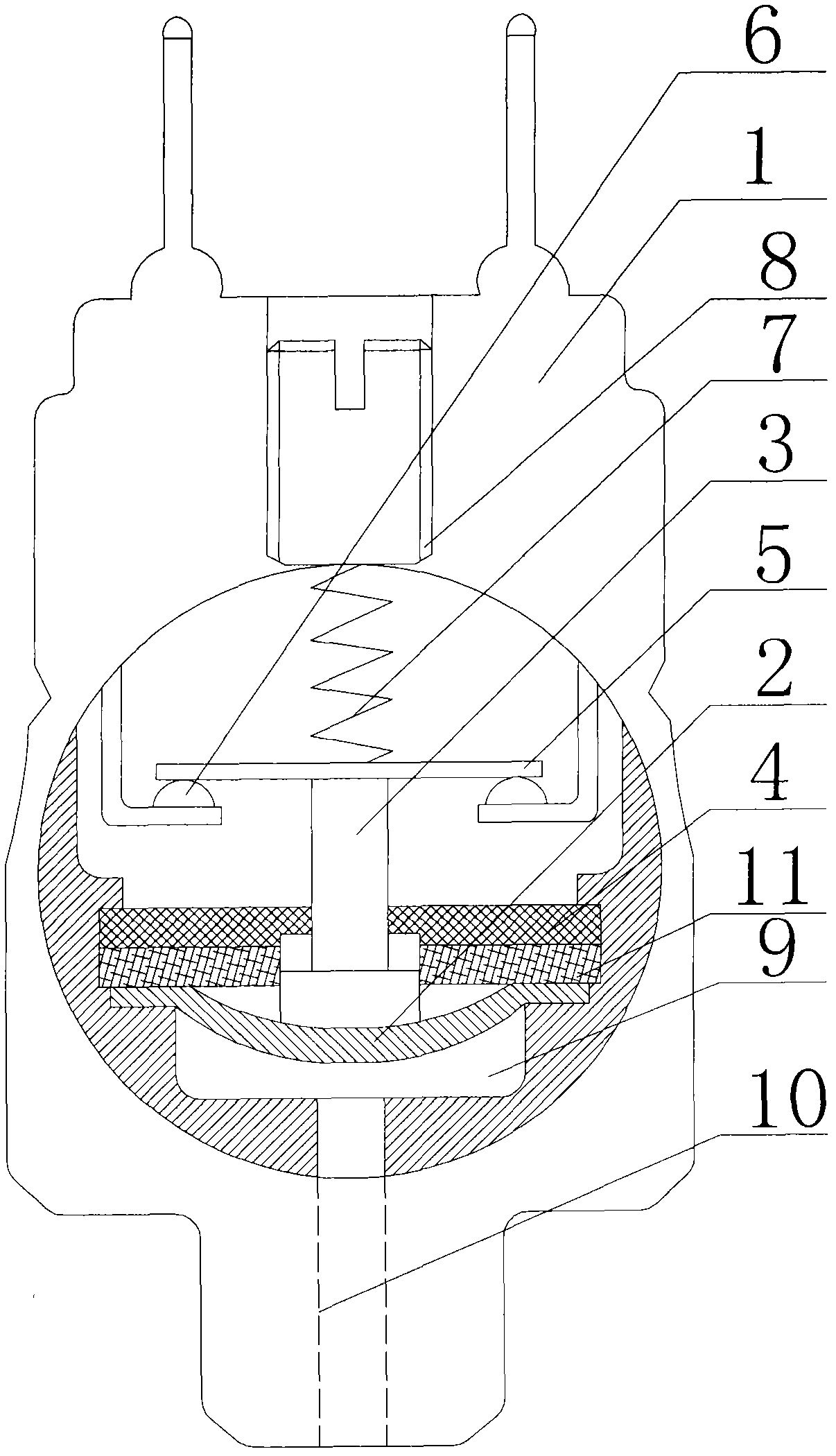

[0016] Such as figure 2 As shown, a pressure switch includes a housing 1, a return diaphragm 2, a ceramic push rod 3, a baffle plate 4, a connecting piece 5 and a connecting contact 6, and the returning diaphragm 2 is placed in the housing 1 , the top of the ceramic mandrel 3 passes through the baffle plate 4 and is connected to the connecting piece 5, the bottom of the ceramic mandrel 3 is in contact with the return diaphragm 2, and the top of the connecting piece 5 is provided with a return spring 7, which passes through the The adjusting screw 8 is fixed in the housing 1, the connecting contact 6 is placed under the connecting piece 5 and is in contact with the connecting piece 5, and a closed pressure chamber 9 is formed between the return diaphragm 2 and the housing 1, The bottom of the casing 1 is provided with a pressure channel 10 communicating with the pressure chamber 9 . In order to improve the precision and sensitivity of the return diaphragm 2 , the baffle 4 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com