Cladding panel and method for manufacturing same

A technology for exterior wall panels and manufacturing methods, applied to chemical instruments and methods, building structures, building components, etc., can solve problems such as deformation, and achieve the effects of reducing manufacturing costs, reducing density, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those skilled in the art can easily implement them. However, the present invention can be implemented in many different forms and is not limited to the embodiments described here. Similar parts are assigned the same reference numerals in the description.

[0038] Below, refer to Figure 1 to Figure 5 An exterior wall panel according to an embodiment of the present invention will be described.

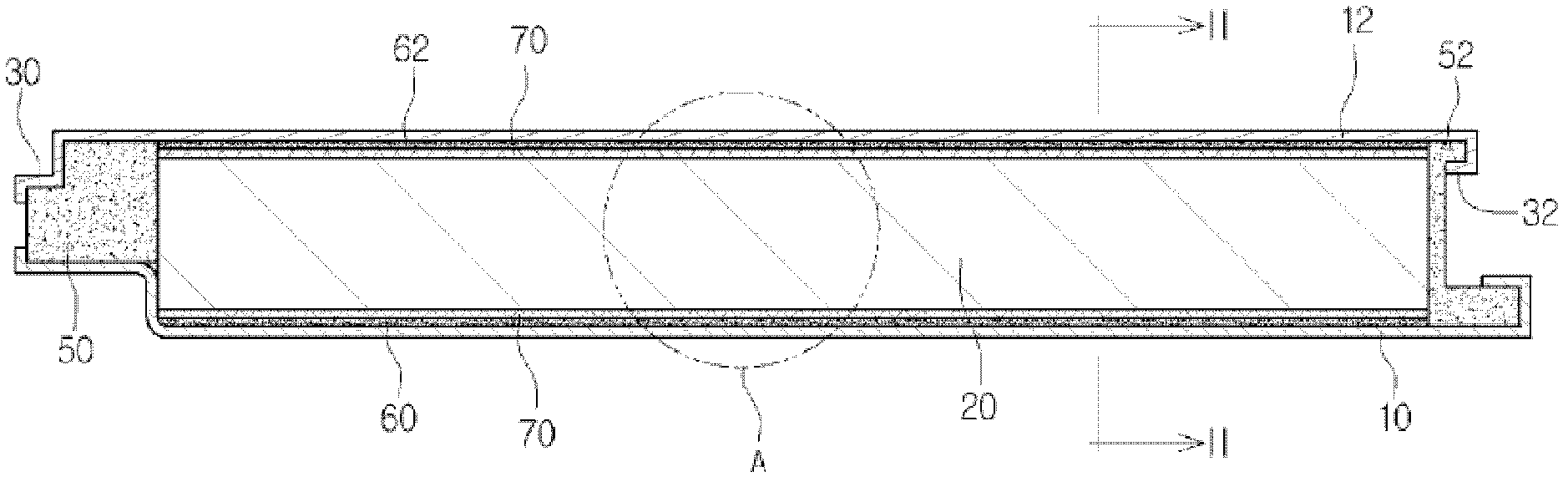

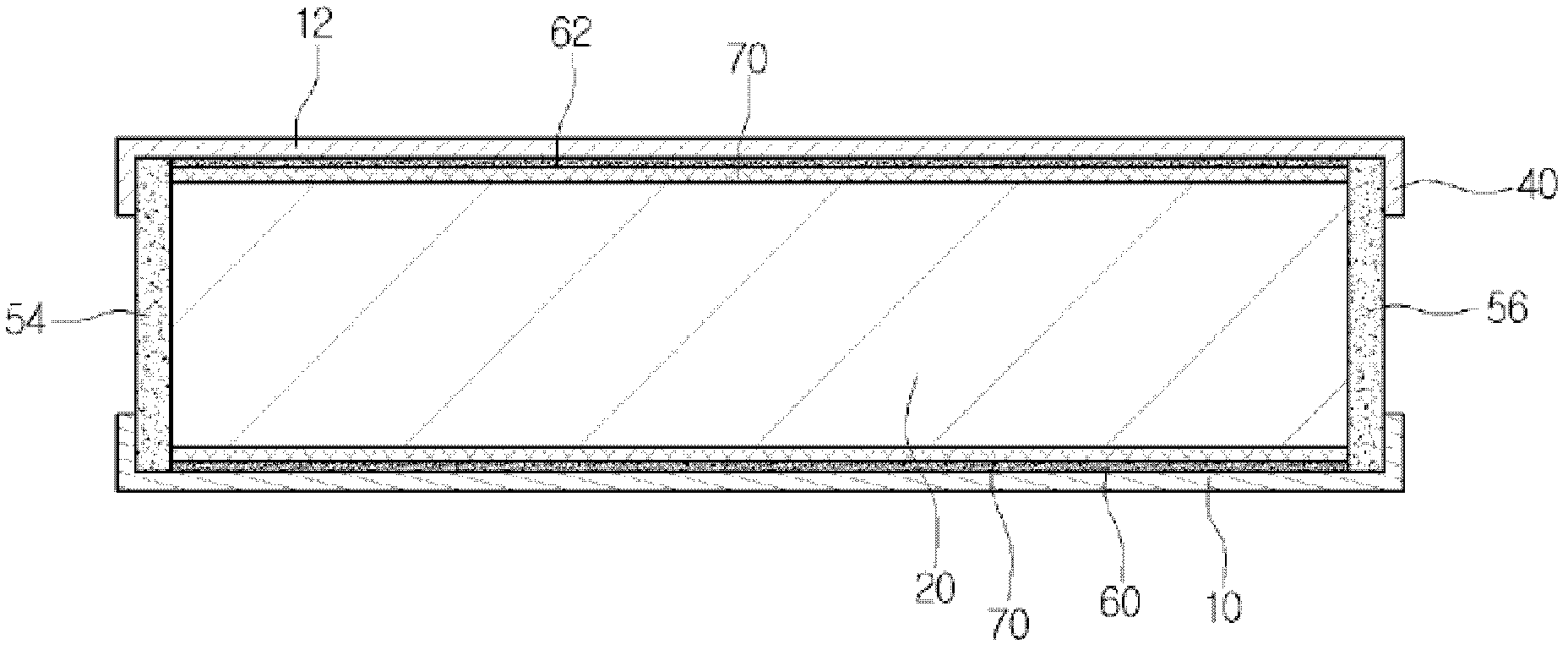

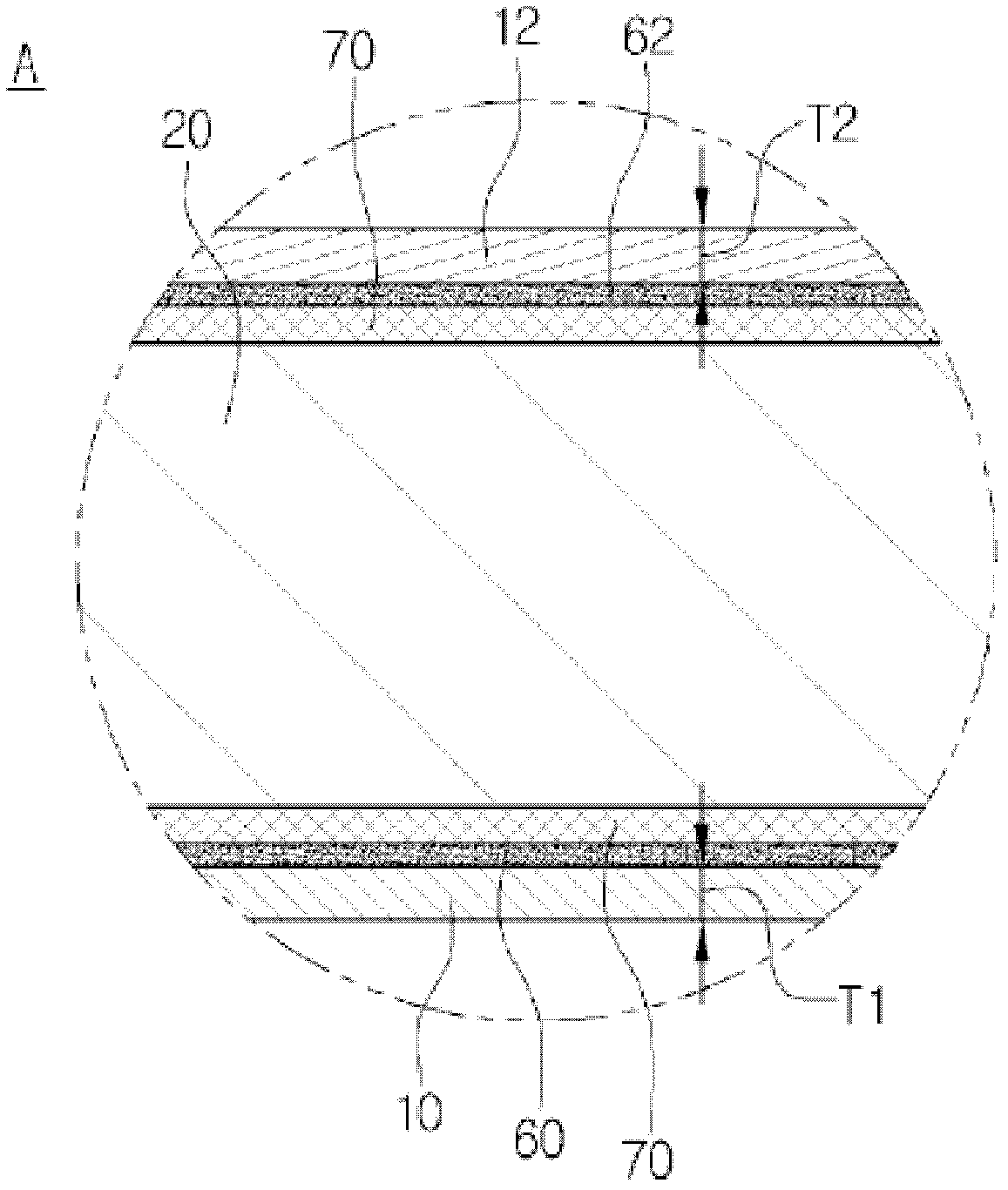

[0039] figure 1 It is a cross-sectional view of an exterior wall panel according to an embodiment of the present invention, figure 2 will be figure 1 Sectional view taken along line II-II, image 3 yes figure 1 Enlarged view of part A.

[0040] refer to Figure 1 to Figure 3 , The exterior wall panel involved in this embodiment includes: a first board 10 , a second board 12 and a core board 20 bonded between the two boards 10 , 12 .

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com