Smooth bore type synchronous flushing water-saving water closet

A technology of flush toilet and sliding hall, which is applied in the structural field of sanitary ware, can solve the problems of water waste and other problems, achieve the effects of not easy to break down, reduce the power of flushing, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings.

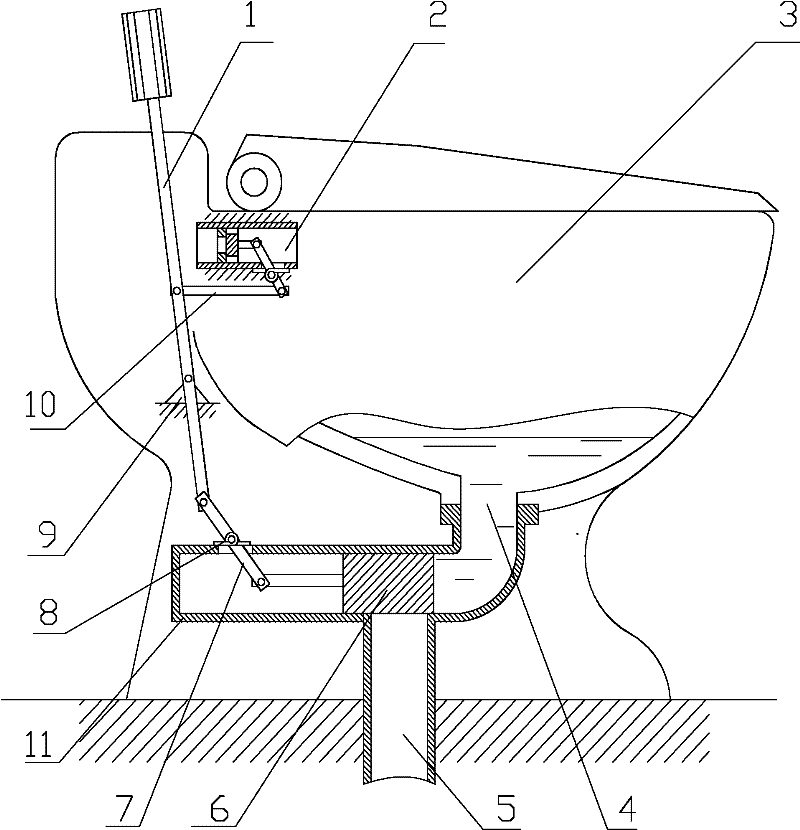

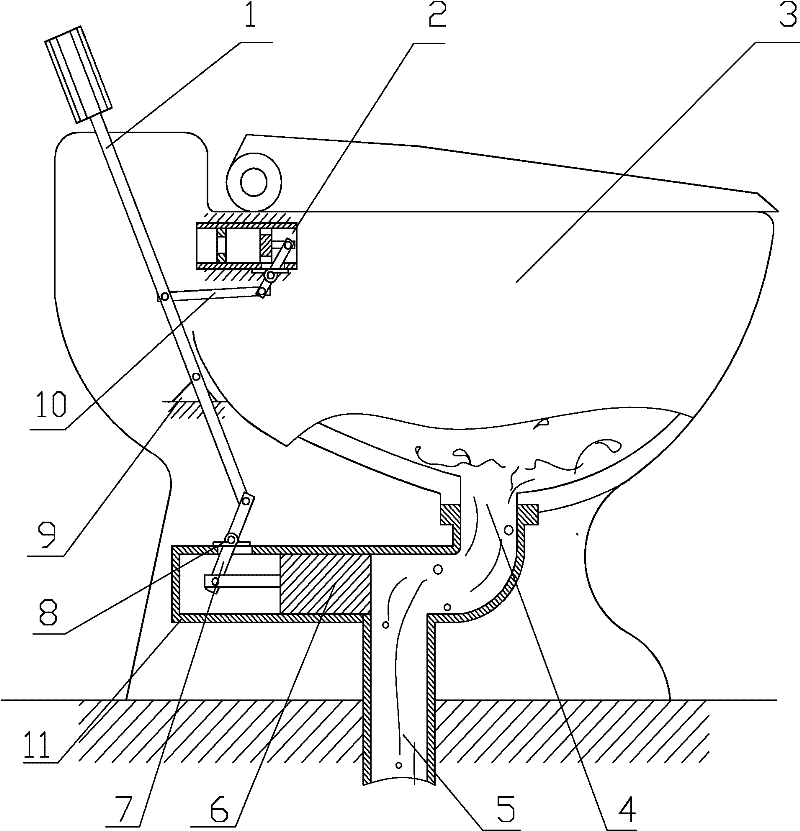

[0024] The water-saving water-saving flush toilet with synchronous flushing in sliding hall type includes a vertical downpipe 4 at the bottom of the toilet 3 and a vertical septic pipe 5 that is misaligned with each other;

[0025] At the dislocation of the sewer pipe 4 and the septic pipe 5, a cylindrical slide chamber 11 is connected horizontally and horizontally;

[0026] Sliding plug 6 is configured in the sliding cavity 11, and the rear side of the sliding cavity 11 stretches out the sliding lever 7 laterally. The lower end of the push rod 1 is hinged at one end of the outside of the slide chamber 11; Push to make the slide plug 6 normal to cover the passage of the septic pipe 5;

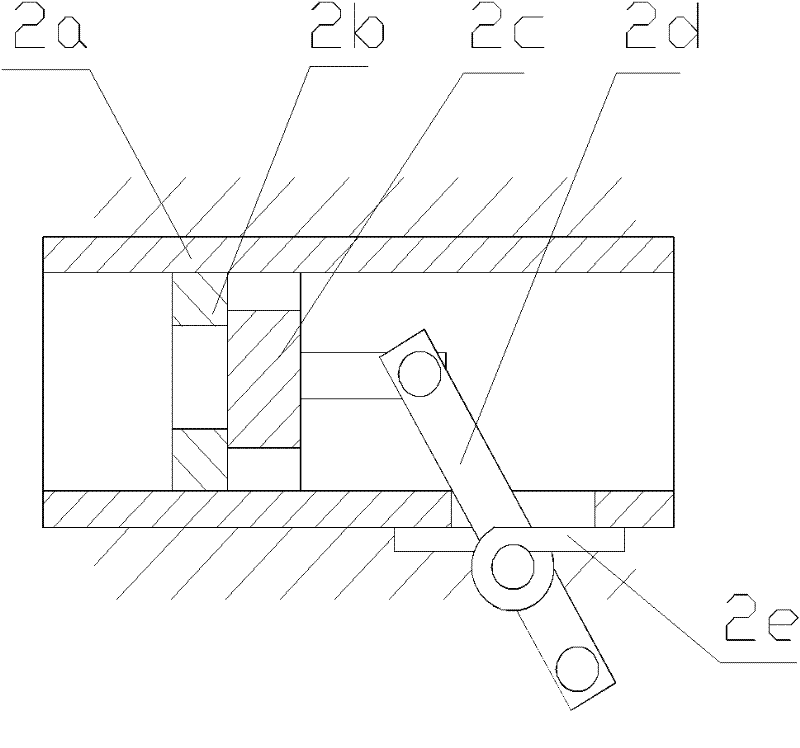

[0027] A pull rod piston valve 2 is set in the flushing route of the toilet 3, the opening and closing of the valve 2c of the pull rod piston valve 2 is controlled by the valve lever 2d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap