Pulley bearing

A bearing and pulley technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of inconvenient use and useless pulleys, and achieve the effects of ensuring personnel safety, flexible use and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

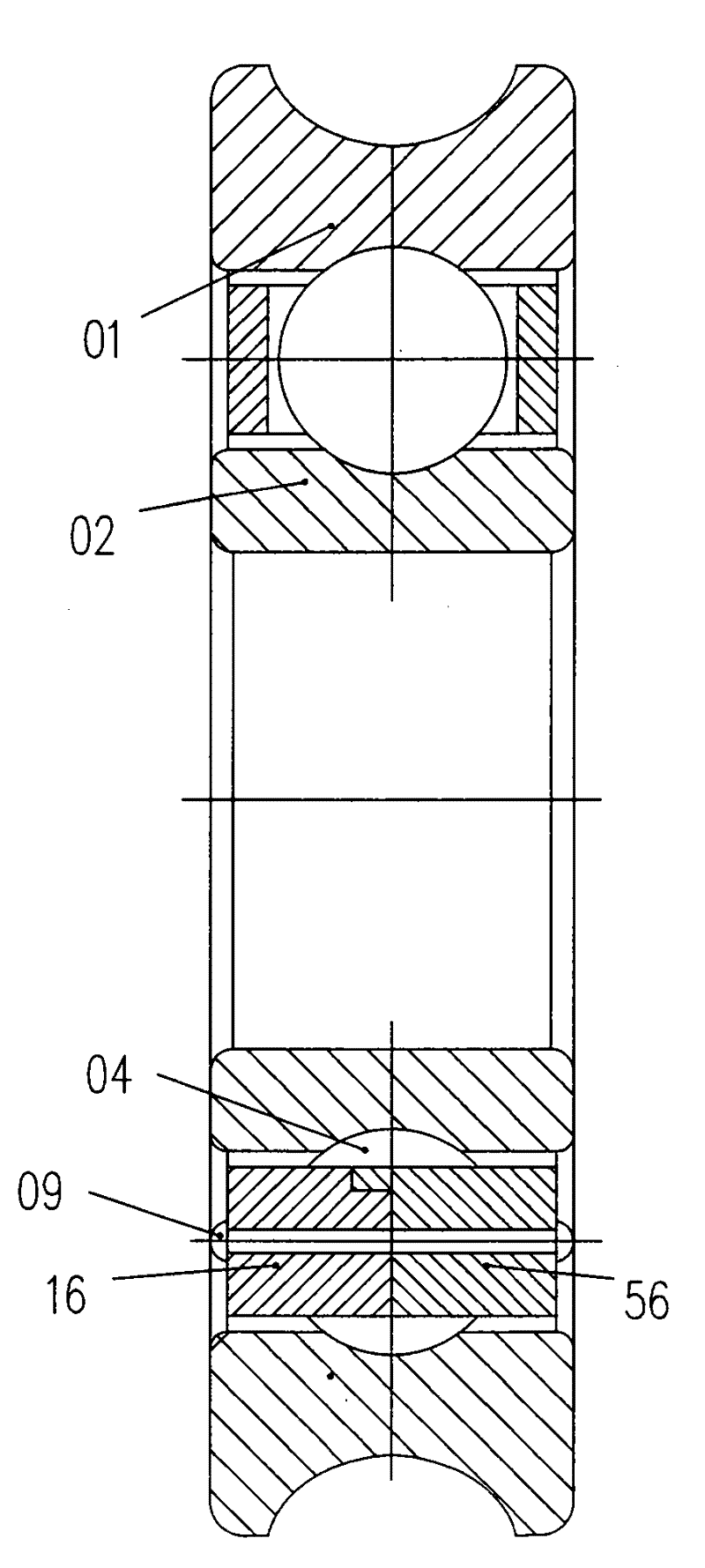

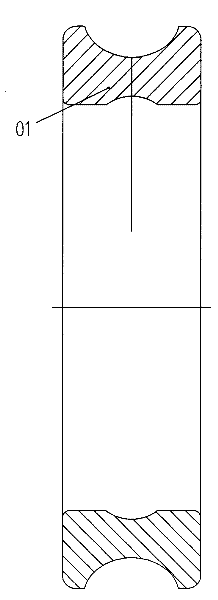

[0008] Such as figure 1 The shown deep groove ball bearing with a pulley groove on the outer diameter of the outer ring, including the outer ring 01, the inner ring 02, the first cage 16 and the second cage 56, steel balls 04, rivets 09; the outer diameter of the outer ring 01 There is a crescent-shaped pulley groove, which only needs to be finely turned, without grinding, which reduces the cost, and increases the friction force during use to solve the problem of relative sliding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com