Form, position and dimension measuring method of blisk blade and tool thereof

A technology of integral blisks and measuring tools, applied in measuring devices, instruments, etc., can solve the problems of high cost, inability to perform real-time monitoring, and long detection period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The steps of the method for measuring the shape and size of the blisk blade described in this embodiment are:

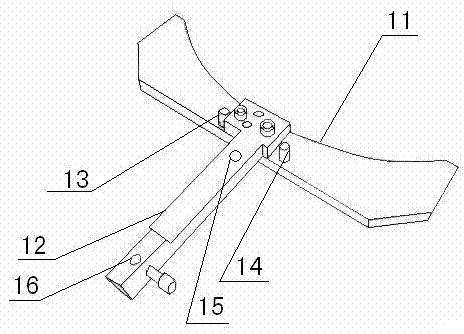

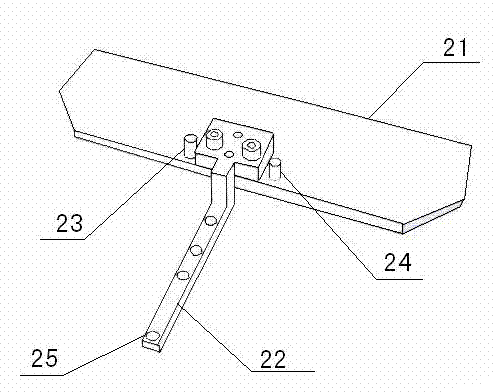

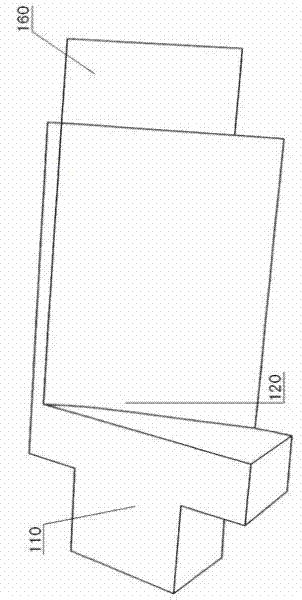

[0032] (1) The position measurement tool takes the circular arc peripheral surface of the blisk as the measurement reference plane, and the positioning plate I (11) is fixed on the blisk through its bottom surface and the positioning pin I (13) and positioning pin II (14). On the circular arc peripheral surface, the positioning pin III (15) pins a point on the profile surface of the blade root; use the position measuring tool to adjust the dial gauge to zero on the standard part of the table; use the measuring pin I (16) of the dial gauge before processing Fix it on the measuring rod I (12), select any point on the top surface of the blade as the measuring point, and use the dial gauge to measure the change of the gauge value of the measuring point as +0.1mm. The distance change in the direction is +0.1mm. After processing, measure again according to the steps...

Embodiment 2

[0035] The steps of the method for measuring the shape and size of the blisk blade described in this embodiment are:

[0036] (1) The position measurement tool takes the circular arc surface of the blisk as the measurement reference plane, and the positioning plate I (11) is fixed on the blisk through its bottom surface and the positioning pin I (13) and positioning pin II (14). On the circular arc peripheral surface, the positioning pin Ⅲ (15) pins a point on the profile surface of the blade root; use the position measuring tool to adjust the dial gauge to zero on the standard part of the table; fix the dial gauge on the measuring pin Ⅰ before processing. On the rod Ⅰ, select any point on the top surface of the blade as the measurement point, and use the dial gauge to measure the change of the gauge value of the measurement point is +0.2mm, and the distance change of the measurement point relative to the normal direction of the measurement reference plane The measurement is +...

Embodiment 3

[0039] The steps of the method for measuring the shape and size of the blisk blade described in this embodiment are:

[0040] (1) The position measurement tool takes the circular arc surface of the blisk as the measurement reference plane, and the positioning plate I (11) is fixed on the blisk through its bottom surface and the positioning pin I (13) and positioning pin II (14). On the circular arc peripheral surface, the positioning pin Ⅲ (15) pins a point on the profile surface of the blade root; use the position measuring tool to adjust the dial gauge to zero on the standard part of the table; fix the dial gauge on the measuring pin Ⅰ before processing. On the rod I, select any point on the top surface of the blade as the measurement point, and use the dial gauge to measure the change of the gauge value of the measurement point is +0.13mm, and the distance change of the measurement point relative to the normal direction of the measurement reference plane The measurement is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com