Novel machine tool parameter database system based on Mitsubishi PLC (programmable logic controller)

A database and parameter technology, applied in the field of mechanical processing and manufacturing, can solve problems such as easy accidents, easy input errors, unit and personal losses, etc., to save time and reduce accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific example the present invention will be further described:

[0014] a) Use graphic software to establish a parameter database interface:

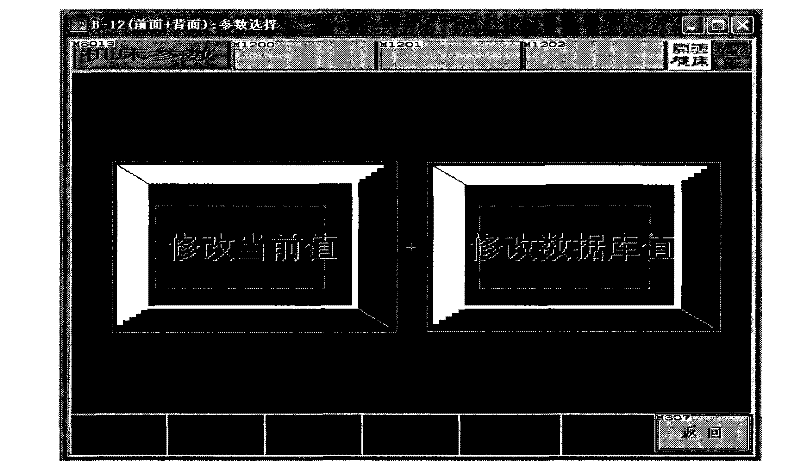

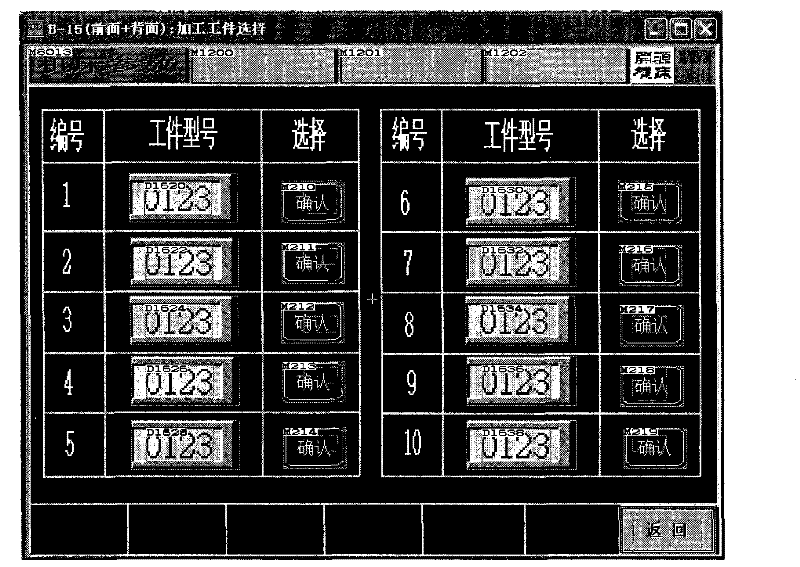

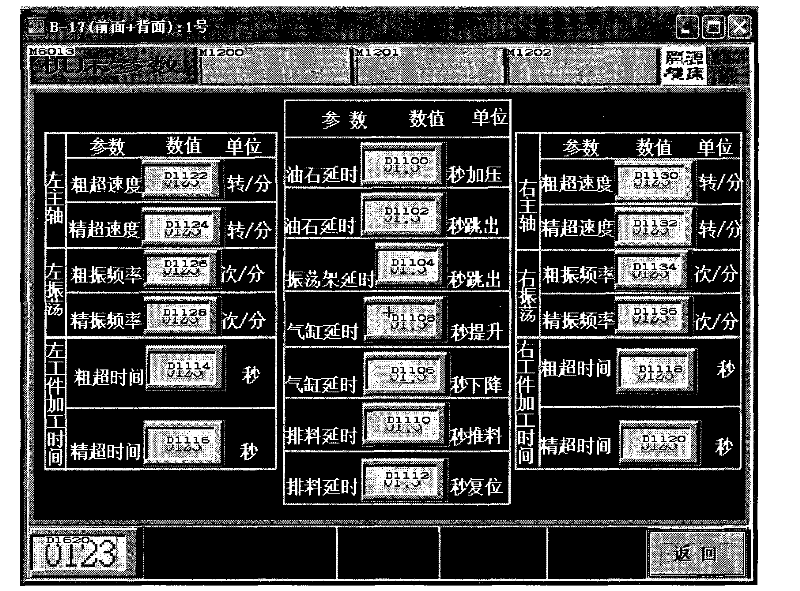

[0015] combined with figure 1 , 2 , 3, 4, 5, using Mitsubishi GT Designer2 to make a graphical interface. Link each control to make variables and data with PLC variables and data. Transfer the program to the touch screen.

[0016] b) Divide the space in the PLC data area and establish a connection with the graphical interface:

[0017] combined with figure 2 , each set of tooling is divided into a section of data space corresponding to the PLC, and this section of data space is used to store a set of processing parameters corresponding to this set of tooling. combined with image 3 , each parameter in the database is linked with the corresponding PLC data address.

[0018] c) Realize the exchange and storage of the database parameter data and the current operation dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com