Single-phase insulating and rectifying transformer

A rectifier transformer, single-phase technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve fire safety hazards and easily generate high-order harmonics current, environmental pollution and other problems, to achieve the effect of suppressing the generation of high-order harmonics, improving the quality of power supply, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the single-phase isolation rectifier transformer of the present invention will be described in detail below with reference to the accompanying drawings.

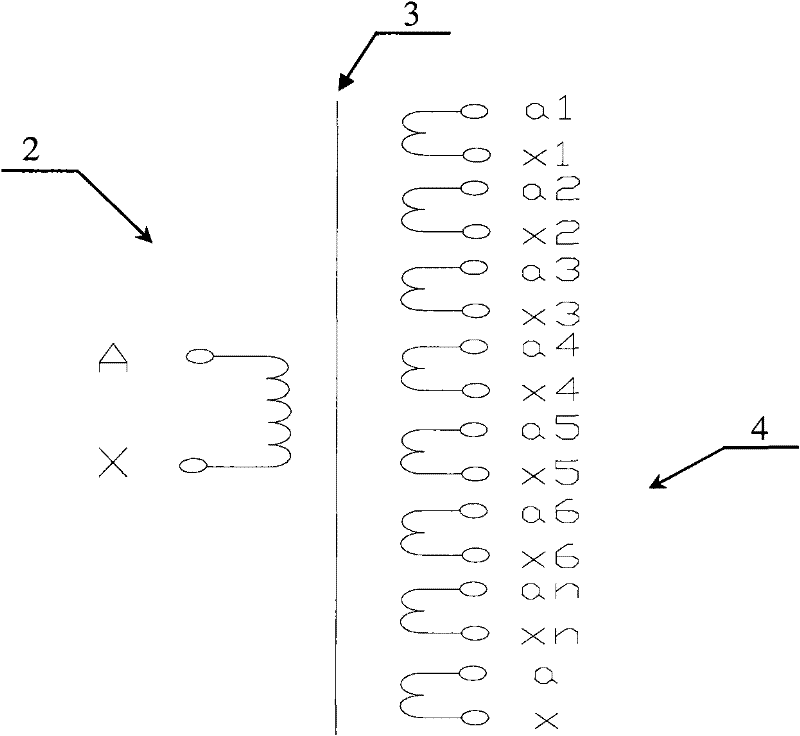

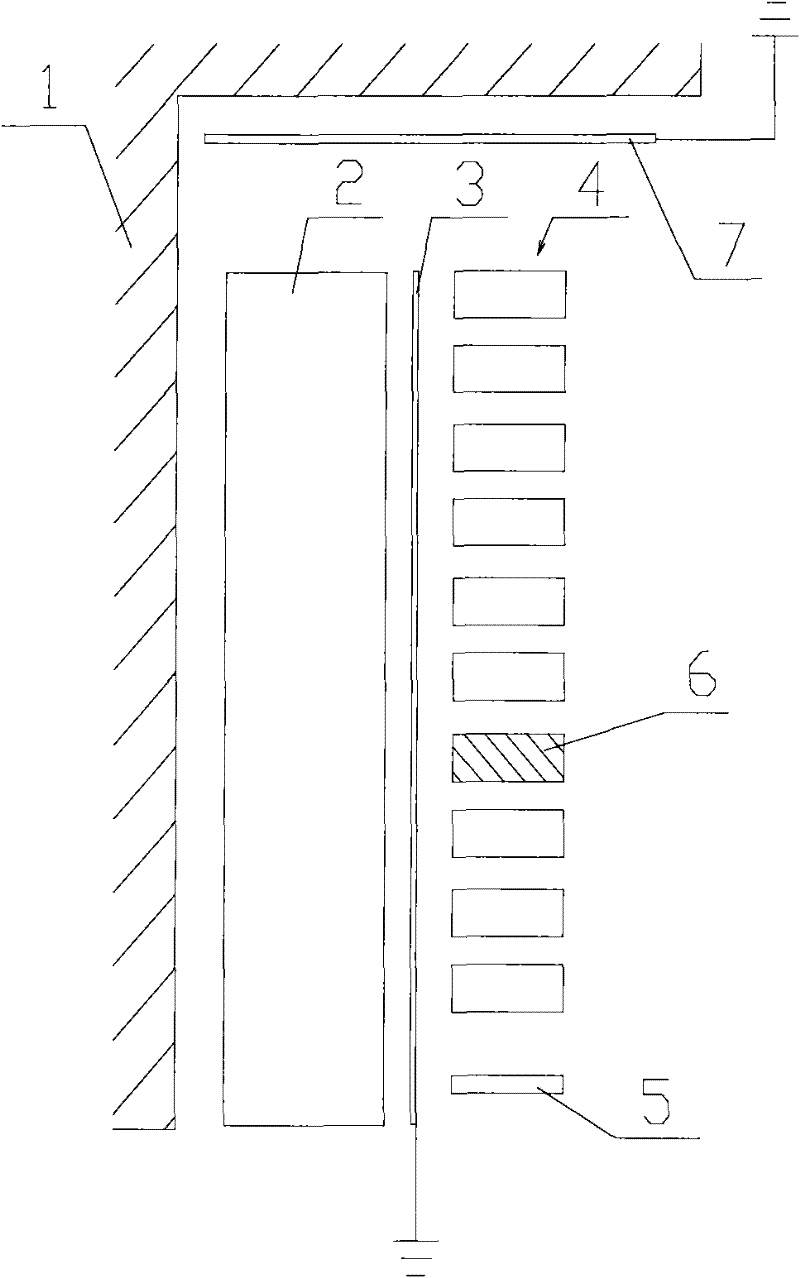

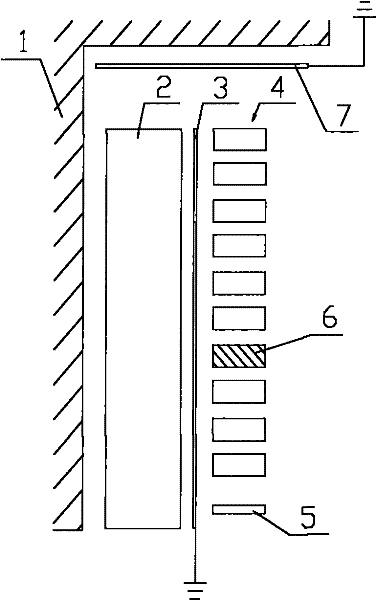

[0024] see figure 1 with figure 2 , is the electrical principle diagram and a partial diagram of the internal structure of the single-phase isolation rectifier transformer of the present invention. In this embodiment, the single-phase isolated rectifier transformer adopts a dry-type rectifier transformer, which includes an iron core 1, a primary winding 2, a first electric shielding component 3, a secondary winding 4, an auxiliary winding 5, a spare unit segment 6 and a second Electric shielding part 7.

[0025] Among them, core 1 is a cold-rolled grain-oriented electrical silicon steel sheet, which is superimposed by a 45° three-stage fully oblique joint method, and is fixed by the relatively advanced ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap