Through type non-phase separation balanced power supply electrified railroad traction system

A technology for electrified railways and traction systems, applied in power lines, single-network parallel feeding arrangements, transportation and packaging, etc., can solve problems such as impossible three-phase balanced power supply, large harmonic content in the power grid, and reduced reliability of locomotives. To achieve the effect of improving power supply quality, reducing harmonic content, and eliminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

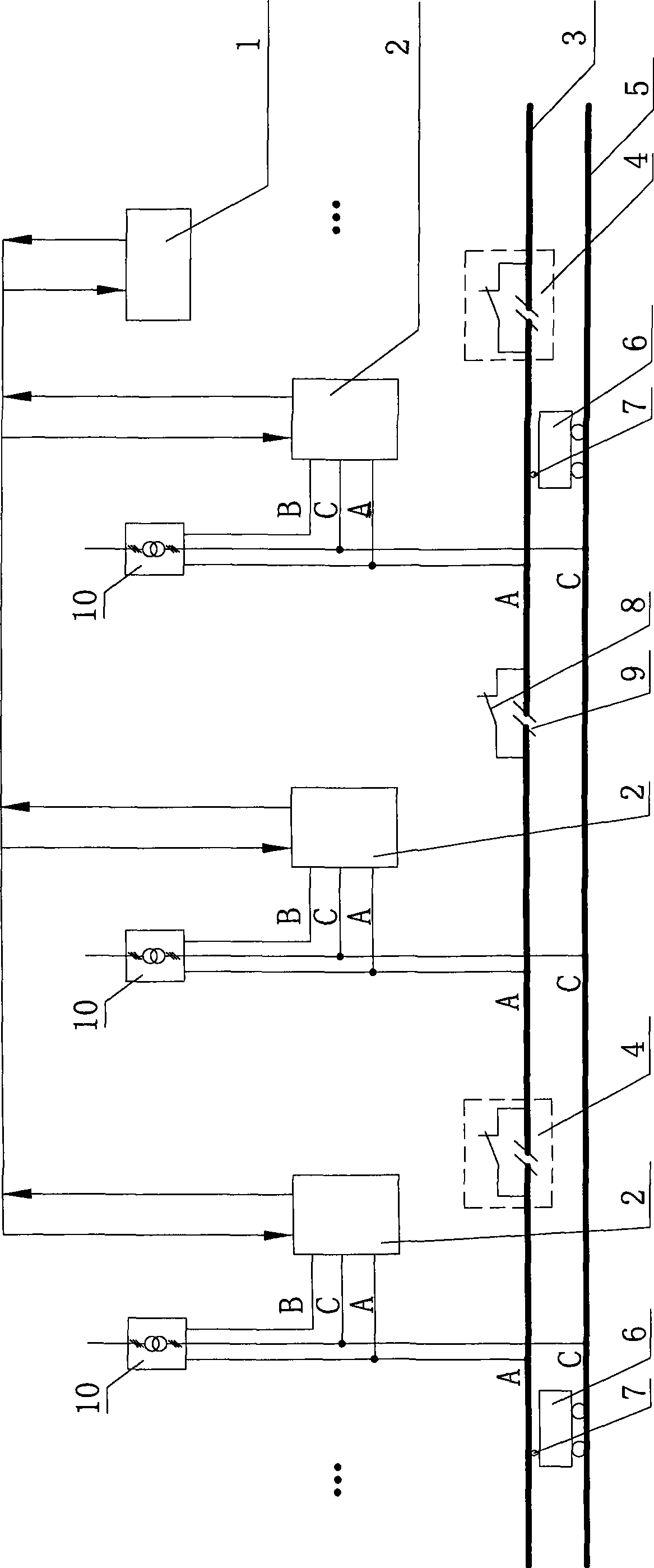

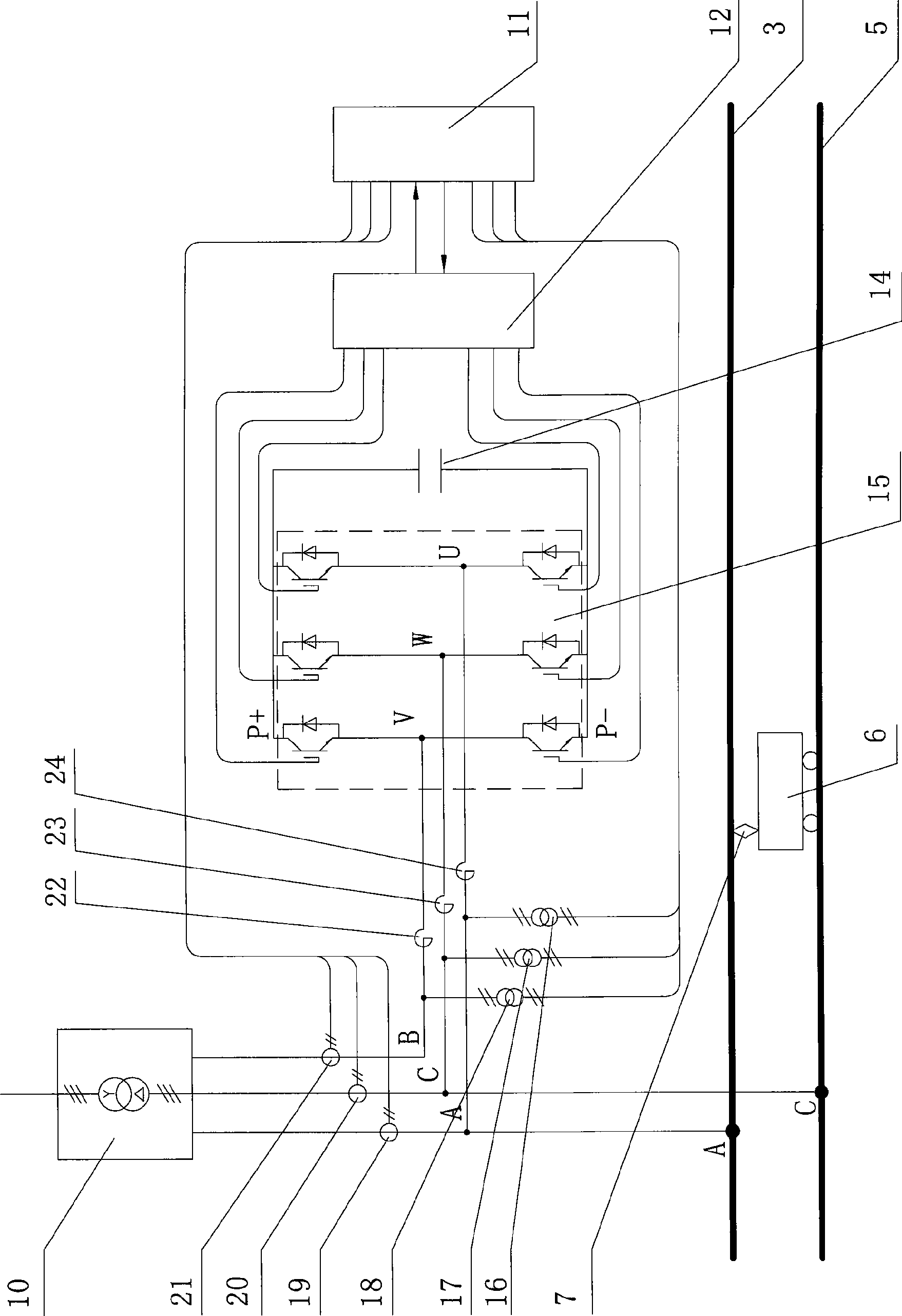

[0012] see figure 1 , the through-type electrified railway traction system with no phase separation and balanced power supply is transformed on the basis of the existing segmented traction power supply network in this embodiment. That is, the traction transformer 10 and catenary 3 of the original traction power supply network of each section are used, and a switch 8 is connected in parallel to the original electric phase splitter 9 to form a current equalizer 4, and the current equalizer 4 is used to connect each traction section. The catenary thus constitutes a through-type traction power supply network. The advantage of doing this is that when a partial fault occurs in the traction power supply network, the faulty network segment can be disconnected by turning off the switch 8 of the current equalizer of the segment, and segmental maintenance can be carried out. The traction transformer 10 of each traction power supply network is equipped with an energy distribution regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com