Method for manufacturing circuit boards

A manufacturing method and circuit board technology, which are applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as unfavorable circuit board quality, separation of adhesive layers, and high stress on the connection part of flexible printed circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The manufacturing method of the circuit board provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

[0040] The first embodiment of the technical solution provides a method for manufacturing a circuit board, which includes the following steps:

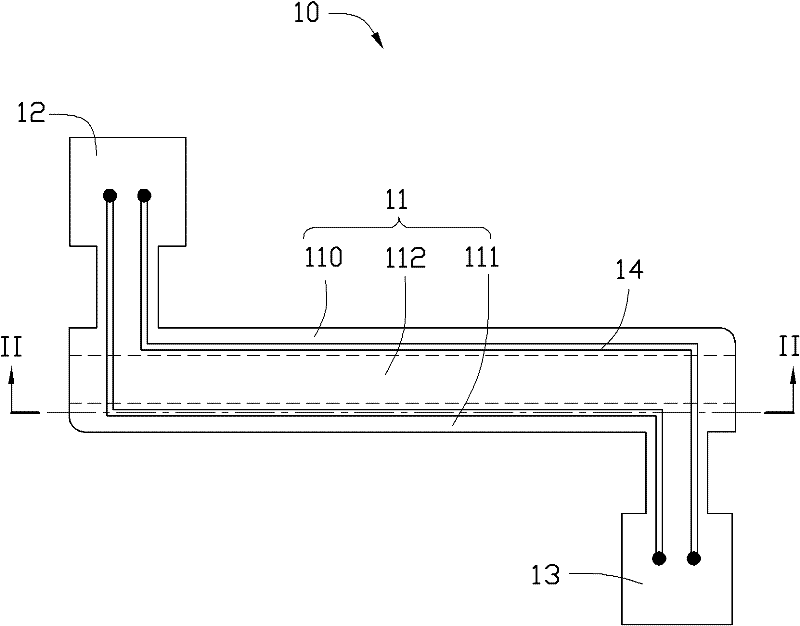

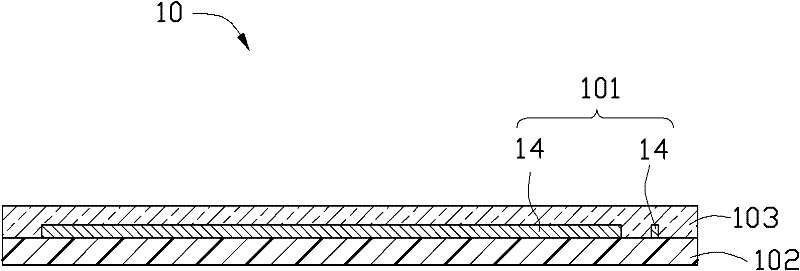

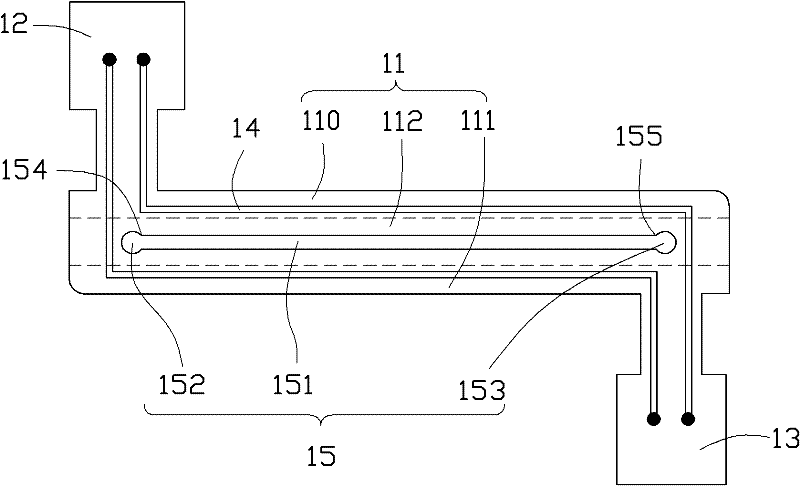

[0041] For the first step, please also refer to figure 1 with figure 2 , a flexible circuit board 10 is provided, which includes a connecting portion 11 , a first flexible substrate portion 12 and a second flexible substrate portion 13 . The connecting portion 11 is in the shape of a cuboid. The connection portion 11 includes a first connection area 110 , a second connection area 111 and a blank area 112 connected between the first connection area 110 and the second connection area 111 . At least one of the first connection area 110 and the second connection area 111 is distributed with conductive lines 14 . The conductive circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com