Method of safe transfer of filter segments in process of producing multi-segment filters

A filter and transmission component technology, applied in the field of safe transmission, can solve the problems of transmission component collision, damaged component production, segment error placement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

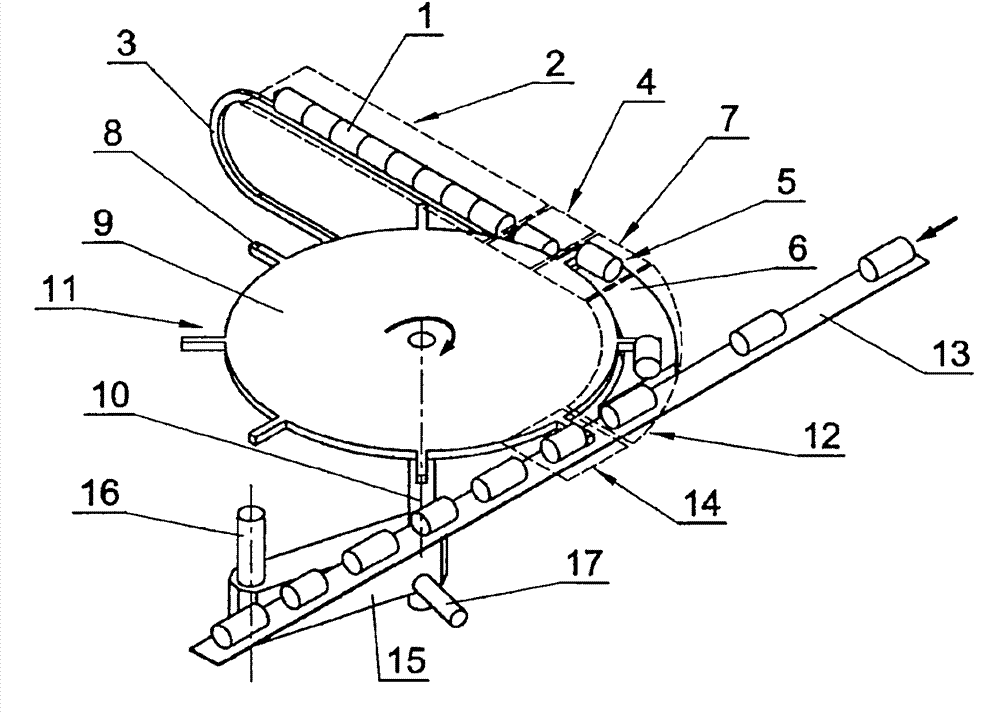

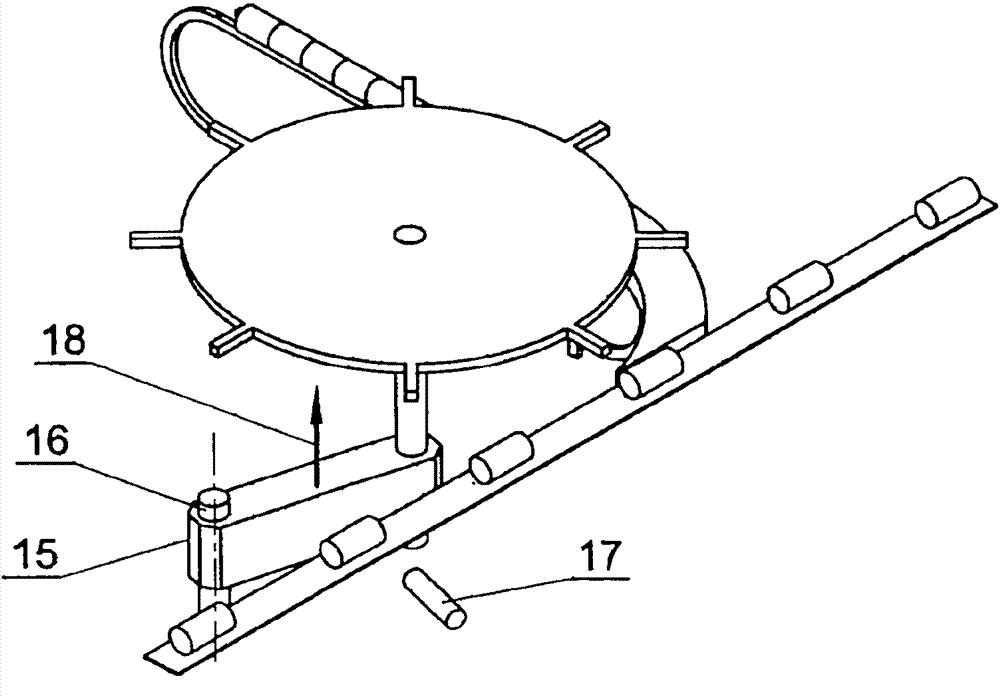

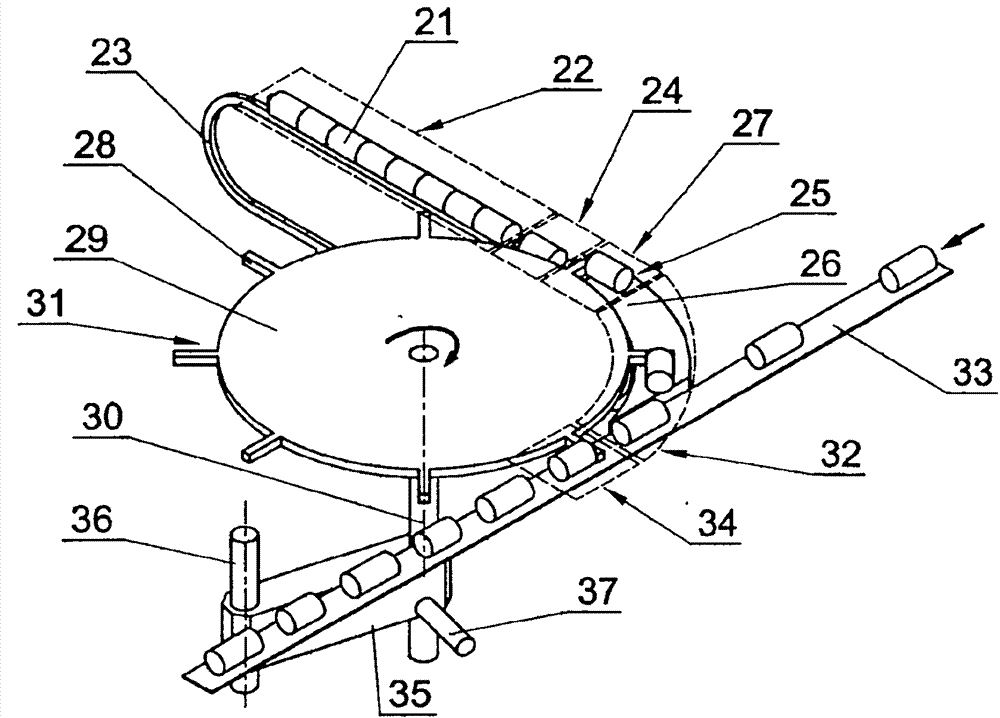

[0005] Example I. figure 1 The situation shown, in which suitable segments 1 are to be made is conveyed in finished strings through zones 2 to 4 comprising a conveyor 3 where the segments are separated by a separating assembly 5 which is a fixed ramp 6, and is conveyed in zone 7 between drives 8 of rotating discs 9 mounted perpendicular to the horizontal axis 10, which constitute a conveying assembly 11. Said separated segment 1 intercepted by the drive 8 in zone 7 is conveyed individually to zone 12 and placed on the horizontal trajectory of the gang belt 13 in zone 14, by which it is conveyed to the next module to produce the desired segment 1 . The shaft 10 of said disc 9 is mounted in a horizontally extending arm 15 slidably mounted on a guide 16 parallel to the shaft 10 , which incorporates a sensor 17 mounted near the shaft 10 . The sensor 17 detects that the position of the disc 9 together with the shaft 10 changes, or the resistance of the movement of the machine inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com