Method for preparing a porous nuclear fuel containing at least one minor actinide

A technology of minor actinides and elements, applied in the direction of reactor fuel elements, reactor fuel materials, nuclear engineering, etc., can solve problems such as the impossibility of obtaining controlled porosity of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

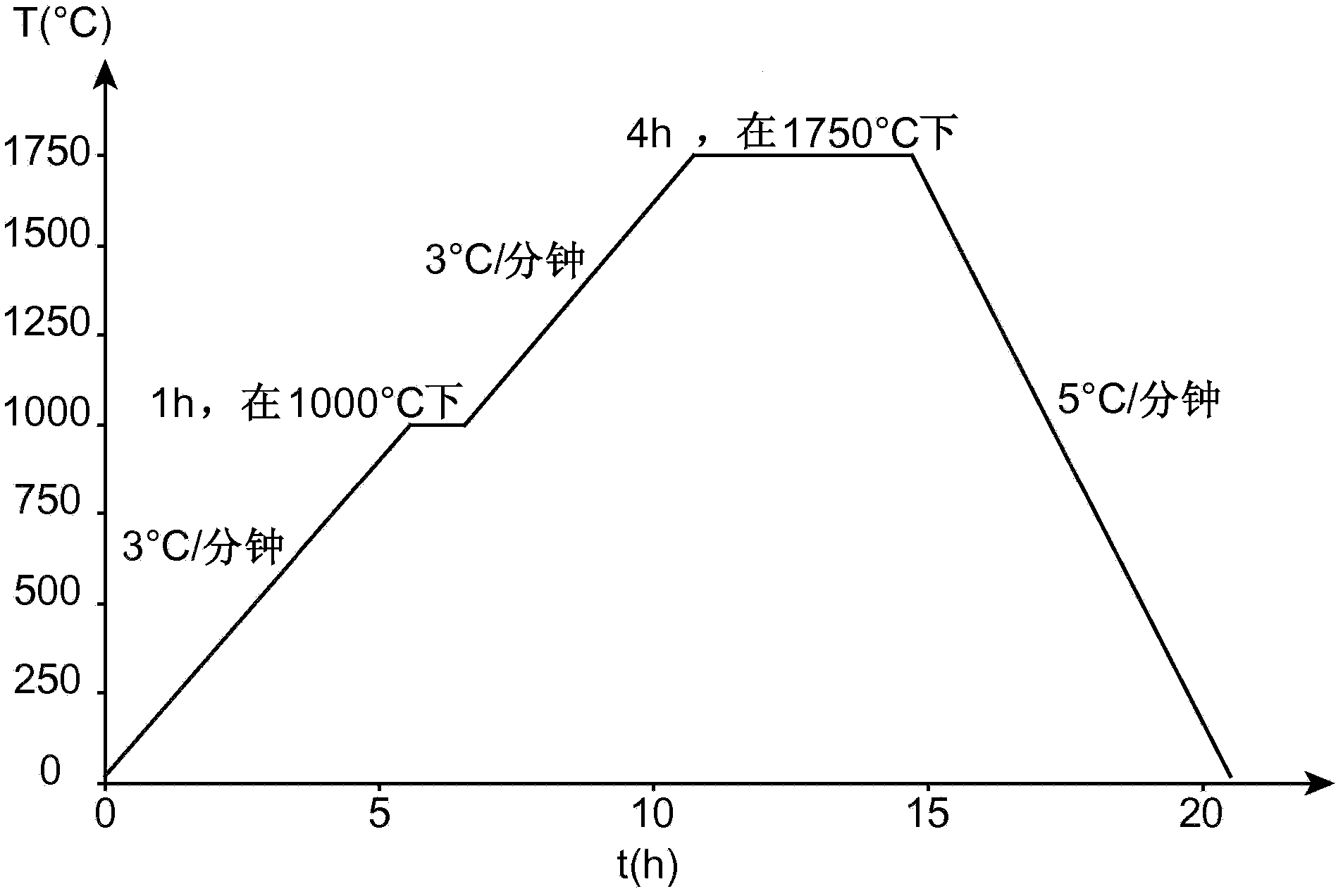

Method used

Image

Examples

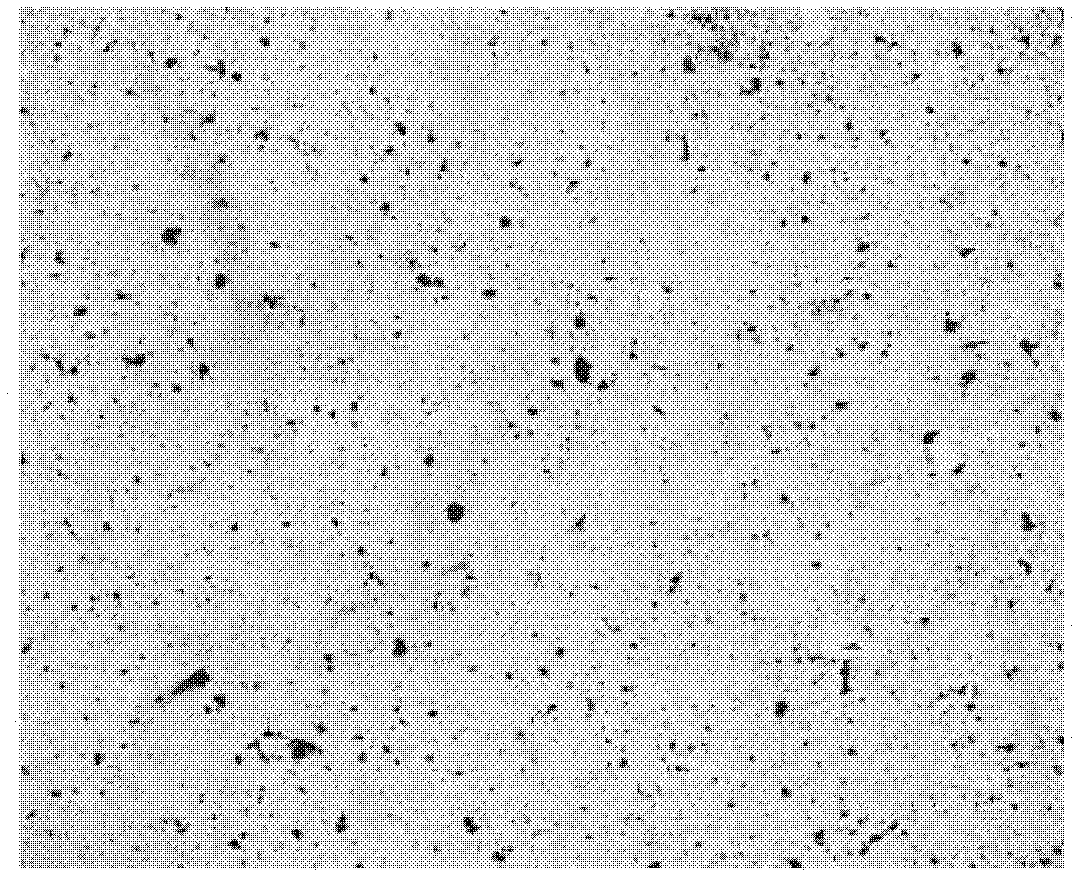

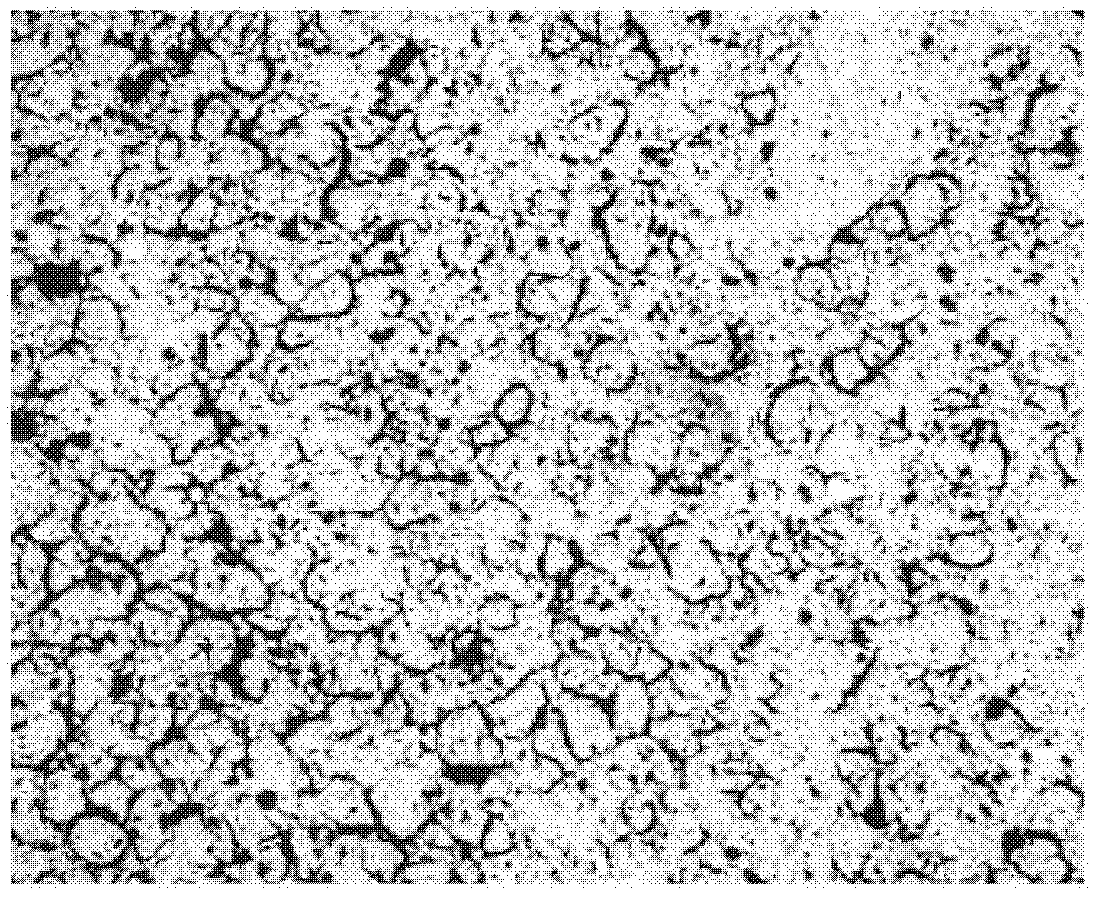

Embodiment 1

[0087] This example illustrates the preparation of a mixed oxide fuel comprising both uranium and americium according to the method of the invention.

[0088] The method applied according to this embodiment comprises the following steps:

[0089]- by grinding 10 g of UO in a stainless steel bowl containing two grinding balls in an oscillating mill at 15 Hz 2 / AMO 2 (according to the U / U+Am=0.9 ratio) the step of co-milling for 30 minutes for the preparation of the first mixture;

[0090] - Prepare a second mixture U with a mass of 10 g in an oscillating mill at 15 Hz in a stainless steel bowl containing two grinding balls within 30 minutes 3 o 8 / AMO 2 , while observing the step of U / U+Am=0.9 ratio. Based on the mass of the final mixture, U was introduced in an amount of 40% by mass 3 o 8 .

[0091] - for the first mixture UO 2 / AMO 2 Steps for storage in stainless steel containers;

[0092] - in parallel, with the matrix and the lubrication of the piston (with stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com