Antioxidant low-expansion high-temperature alloy

A high-temperature alloy, low-expansion technology, applied in the field of high-temperature alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further explained below in conjunction with specific examples, but it does not limit the present invention.

[0041] The specific alloy composition is as follows:

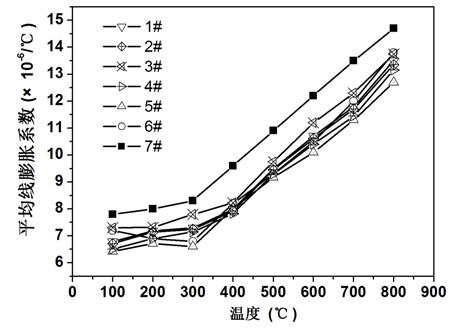

[0042] Alloy No. Fe co Ni Nb Ti Si Cr Al Zr B Example 1 Bal. 26 27 3.8 1.0 0.1 2.8 1.5 0.05 0.028 Example 2 Bal. 29.4 24.5 4.8 0.85 0.27 2.0 1.75 0.11 0.018 Example 3 Bal. 29.4 24.5 4.8 0.85 0.27 3.4 0.8 0.02 0.013 Example 4 Bal. 29.4 24.5 4.8 0.85 0.27 2.2 2.00 0.15 0.022 Comparative example 1 Bal. 29.4 24.5 4.8 0.85 0.27 1.5 1.45 0.18 0.030 Comparative example 2 Bal. 29.4 24.5 4.8 0.85 0.27 3.0 2.1 - 0.004 Comparative example 3 Bal. 29.4 24.5 4.8 0.85 0.27 5.5 0.45 - 0.006

[0043] The specific preparation methods of the above alloys are that the alloy ingots are smelted by vacuum induction conventional melting process, after homogenizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com