LPI ejector

An injector and injection pipe technology, which is applied to fuel injection devices, machines/engines, mechanical equipment, etc., can solve problems such as injection defects, poor quality of exhaust gas, and uneven fuel supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, an LPI injector according to an exemplary embodiment of the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the exemplary embodiments to be disclosed hereinafter, and the present invention can be implemented in various forms. It will be appreciated by those skilled in the art that changes may be made in these embodiments without departing from the principles and spirit of the general inventive concept, the scope of which is defined in the appended claims and their equivalents.

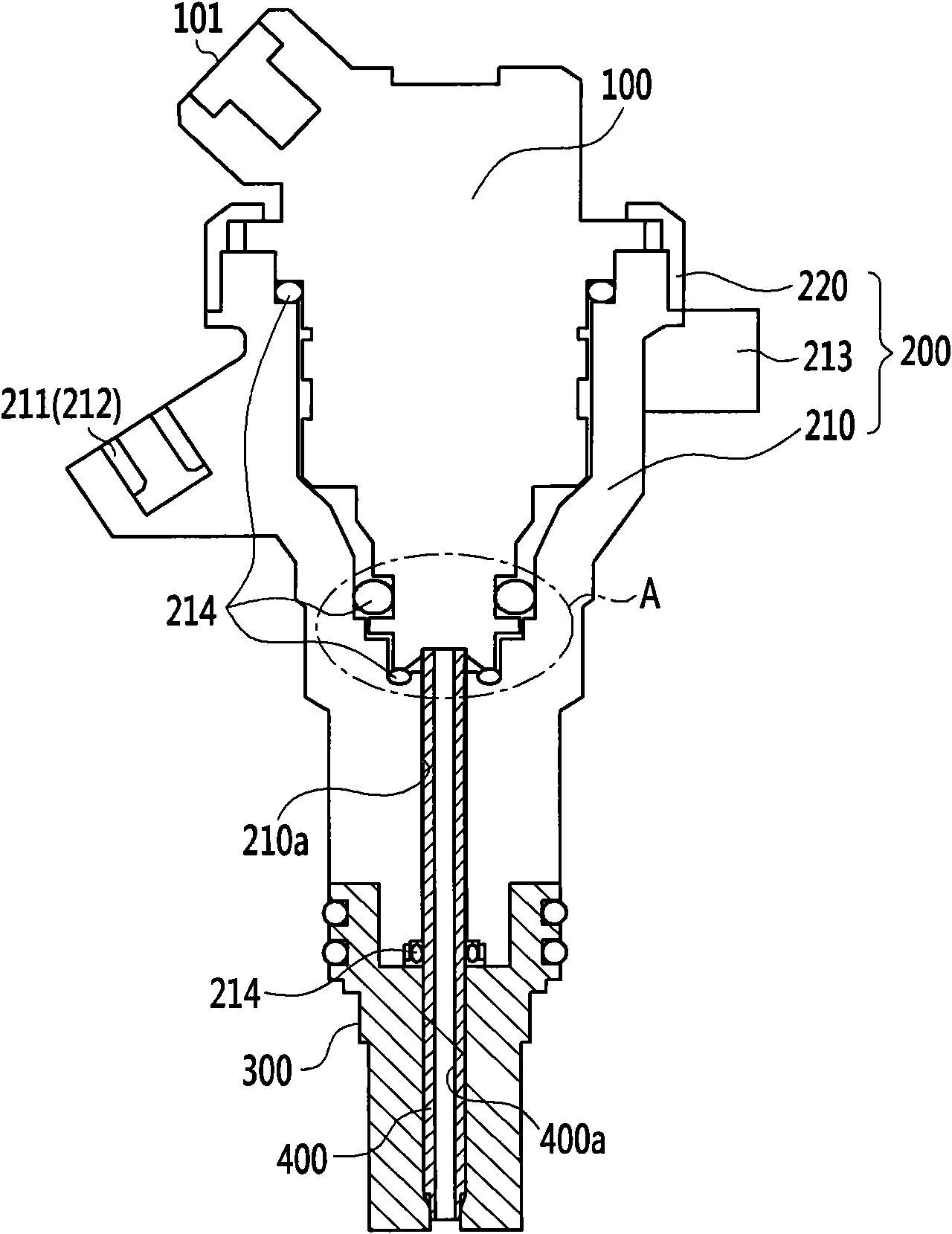

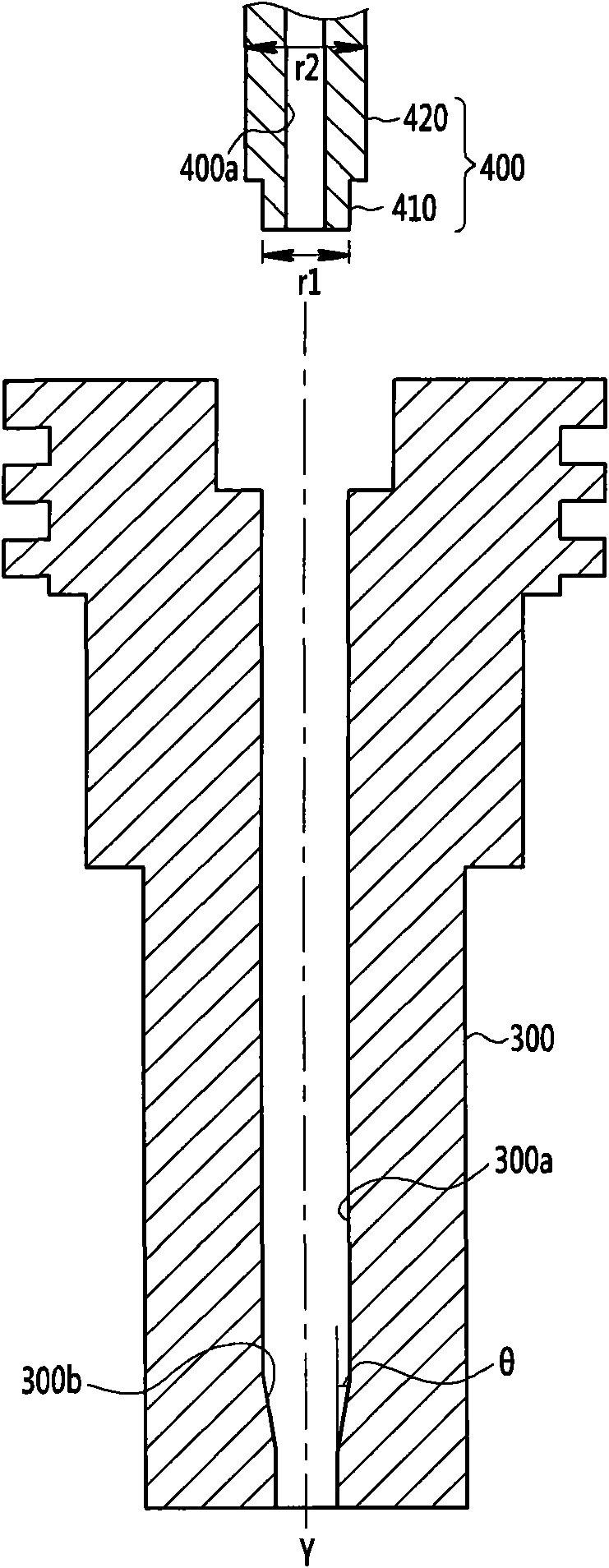

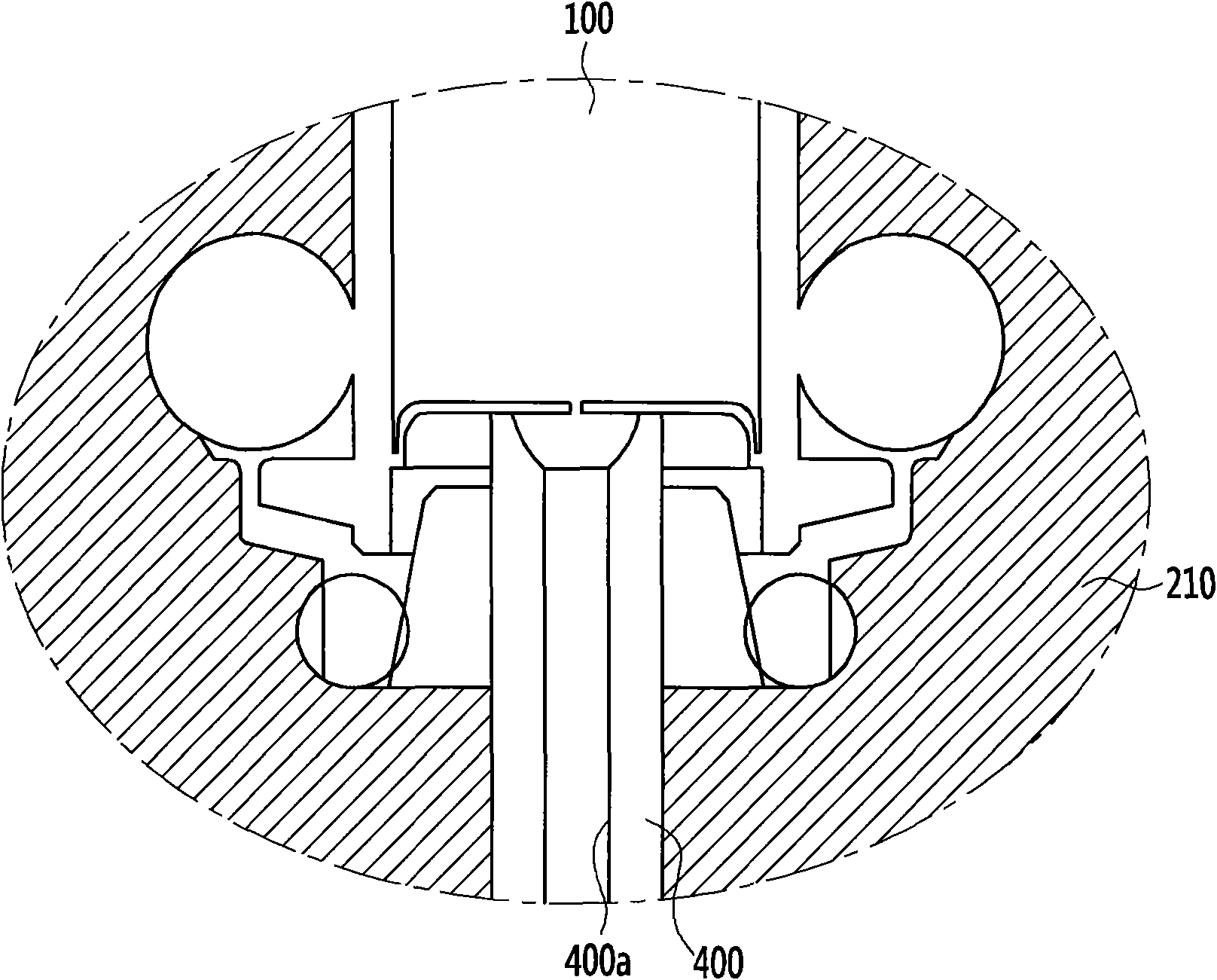

[0026] figure 1 is a cross-sectional view of an LPI injector according to an exemplary embodiment of the present invention, figure 2 yes figure 1 An exploded view of the jet tube and icing tip, image 3 yes figure 1 A magnified view of part A.

[0027] Such as Figure 1 to Figure 3 As shown, the LPI injector according to the exemplary embodiment of the present invention includes: an in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap