A kind of conical bucket type water throwing gas atomizer

A technology of gas atomization and conical barrel, which is applied in the direction of liquid injection device, injection device, etc., can solve the problems of atomization gas quality impact, waste of power source, waste of resources, etc., to ensure the quality of atomization gas and power saving can be achieved Good effect of control and atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

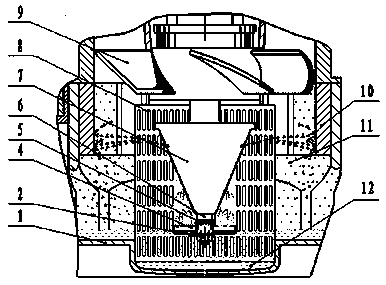

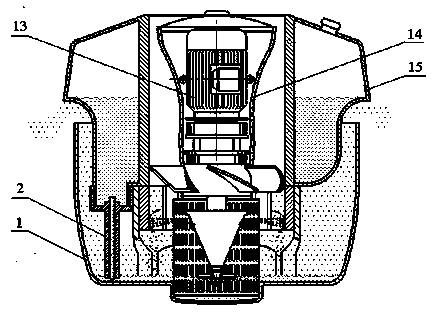

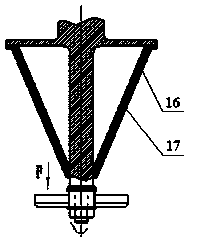

[0020] Embodiment 1: as Figure 1-6 As shown, the conical bucket type water-spinning gas atomizer includes a device housing 1, a water impeller 4, several washers 5, a water-spinning shaft 6, a conical small-hole bucket 7, a cylindrical net 8, fan blades 9, Atomization cylinder 10, bracket 11, motor 13 and water tank 15; shell 1 is a cylindrical structure with a water supply pool 12 at the bottom, a bracket 11 is arranged at the bottom of the inner cavity, and the atomization cylinder 10 is placed on the bracket 11, and the atomization cylinder 10 is The water tank 15 and the motor 13 are placed; the water tank 15 is a ring-column structure whose bottom is provided with an outlet pipe 3 extending from the bottom of the housing 1. Spacing; the rotating shaft 6 and the taper hole rotating shaft 7, the cylindrical net 8, and the fan blade 9 are the same rotating shaft, and its rotating shaft is connected with the output shaft of the motor 13; the lower end of the rotating shaft 6...

Embodiment 2

[0022] Embodiment 2: as Figure 1-6 As shown, the structure of the conical bucket-type water-throwing gas atomizer is the same as that of Embodiment 1. The distance between the lower part of the water tank 15 embedded in the opening of the housing 1 and the housing 1 is 10mm, and the cone-shaped small hole is the bucket. The distance between the 7 upper end and the fan blade 9 is 20mm. The aperture of the aperture 16 on the tapered aperture bucket 7 barrel wall is 1.5mm, and the pitch is 3mm. The number of blades of the water impeller 4 is 6, the draft thickness of the water impeller 4 in contact with the water surface of the water supply tank 12 is 5mm, and the number of the gasket 5 is 5.

Embodiment 3

[0023] Embodiment 3: as Figure 1-6 As shown, the structure of the conical barrel-type water-throwing gas atomizer is the same as that of Embodiment 1. The distance between the lower part of the water tank 15 embedded in the opening of the shell 1 and the shell 1 is 3 mm, and the cone-shaped small hole is the barrel. The distance between the 7 upper end and the fan blade 9 is 5mm. The aperture of the aperture 16 on the tapered aperture bucket 7 barrel wall is 1mm, and the pitch is 1.5mm. The number of blades of the water impeller 4 is 2, the draft thickness of the water impeller 4 in contact with the water surface of the water supply tank 12 is 3 mm, and the number of the gasket 5 is 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com