Non-polar oblique wedge adjustment mechanism

A technology of adjusting mechanism and wedge, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of inaccurate adjustment position, long rolling line adjustment time, complicated device, etc., and achieve a simple structure. Compact, highly automated operation, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

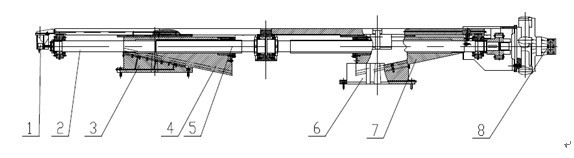

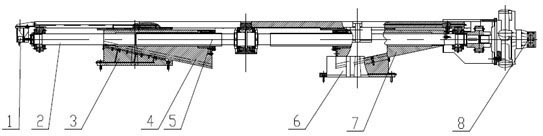

[0011] Example: such as figure 1 As shown, this infinite wedge adjustment mechanism at least includes a lead screw 2, a proximity switch 1, a hydraulic motor 8, two supports, two oblique sliders, a photoelectric encoder and a PLC controller, and is characterized in that: two The first support is fixed on the rolling mill archway; the two oblique sliders are fixed on the same side of the lead screw through nuts; the two supports have chute matching the oblique slider, and the oblique slider is placed in the chute of the support; the hydraulic pressure The motor 8 is connected to the lead screw 2 through a coupling; the stepless wedge adjustment device is connected to the PLC controller and controlled by the proximity switch 1 installed on the lead screw; the stepless wedge adjustment device is also connected to the computer through a photoelectric encoder.

[0012] The lead screw 2 can be equipped with a proximity switch 1 on the left and connected to the PCL controller, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com