Inlet and outlet moving mechanism of core cutter of spring machine

A technology of moving mechanism and movement knife, which is applied in the direction of manufacturing springs, other household appliances, household appliances, etc. from wires, which can solve the problems of all-in, all-out, and cannot meet the advanced technological requirements of secondary bending forming springs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

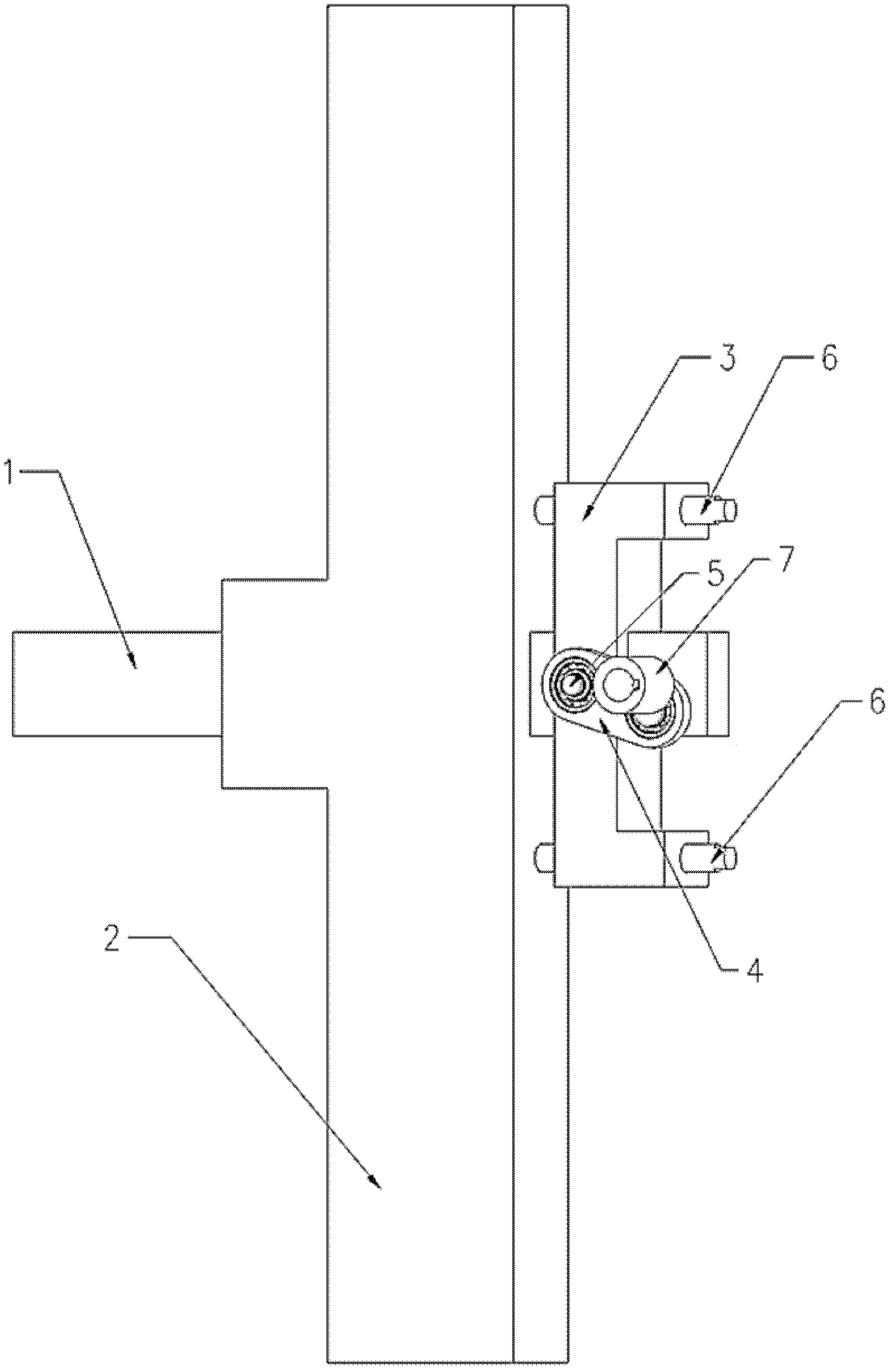

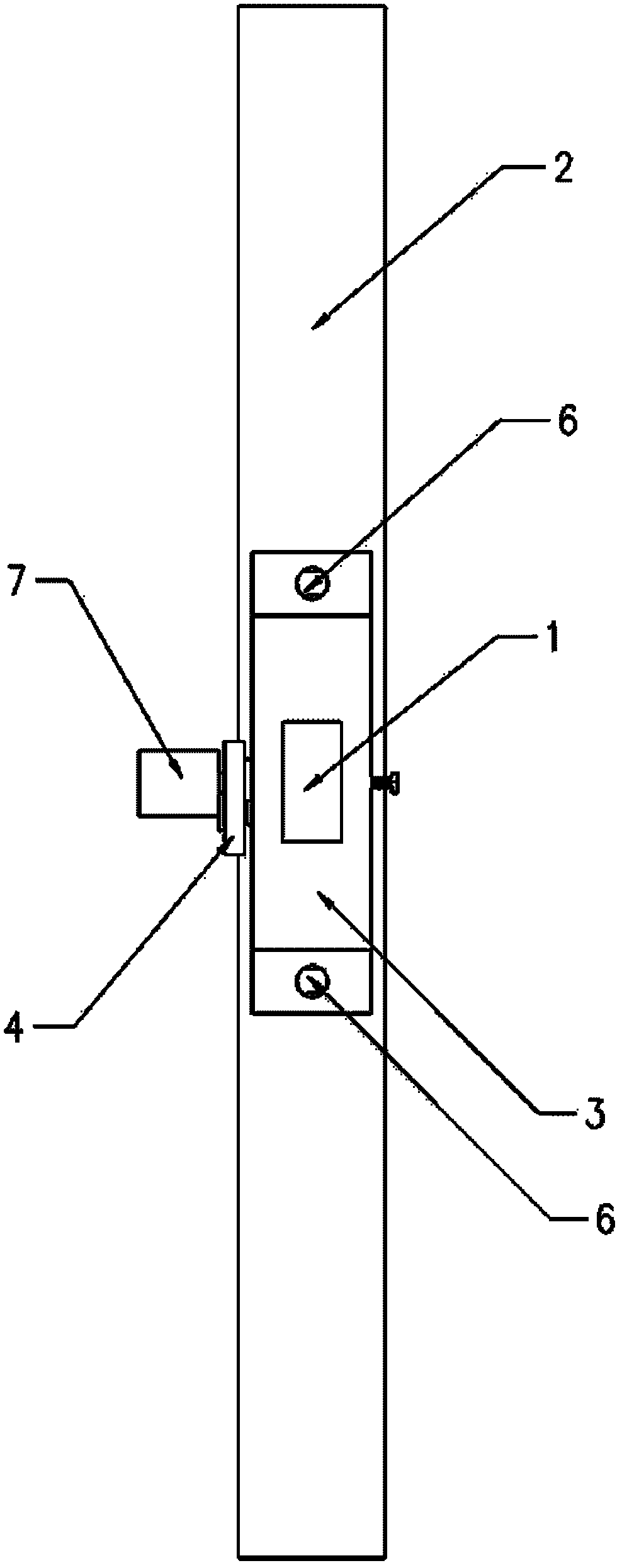

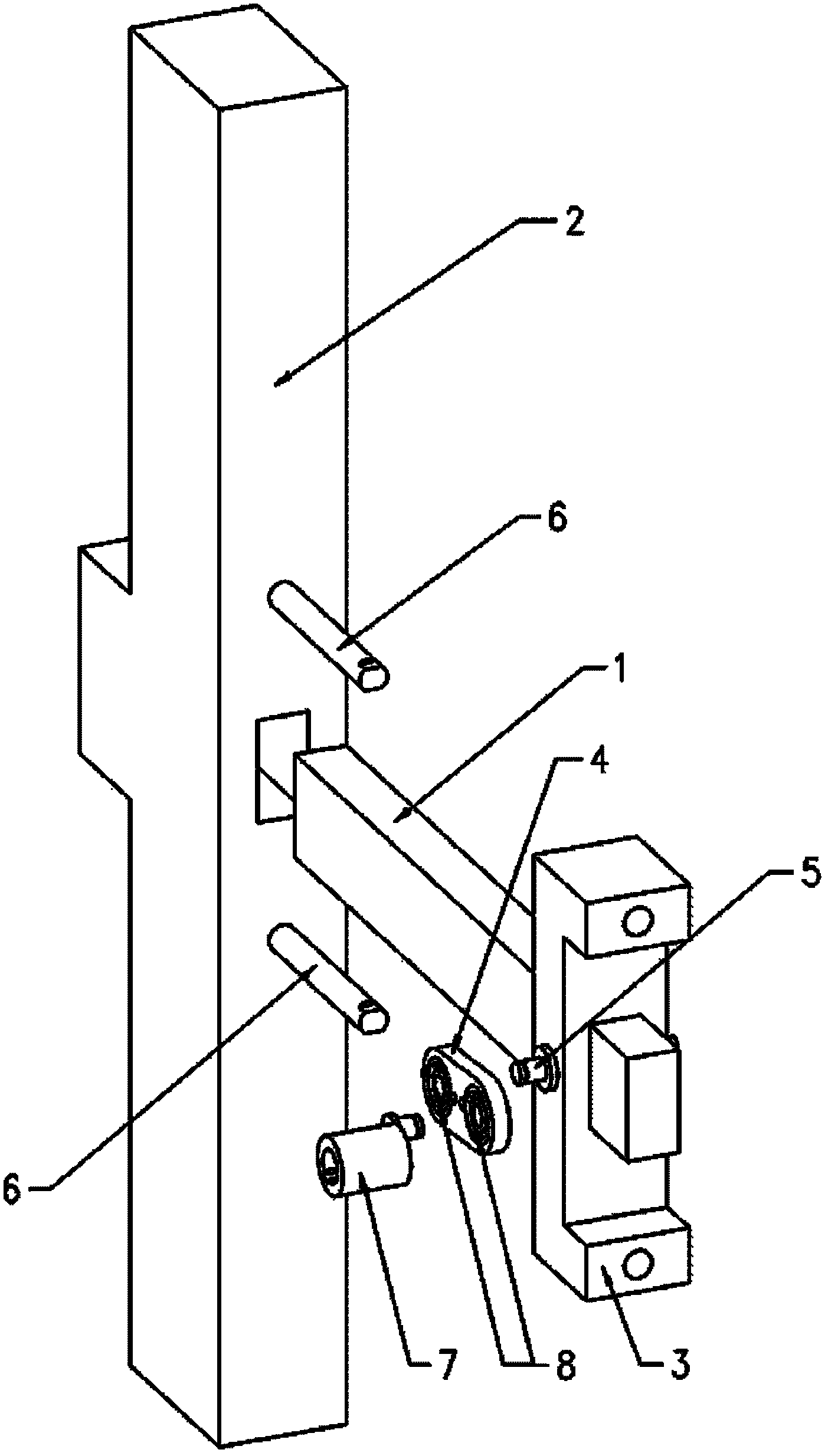

[0017] The in and out movement mechanism of the spring movement knife is as follows: Figure 1-Figure 3 As shown, there is a rectangular through hole protruding in the middle of the core knife seat 2 for installing the core knife 1. The core knife 1 is installed in the through hole of the core knife seat 2 and can slide back and forth. The rear end of the core knife 1 is fixed on the U-shaped seat with bolts. 3 up;

[0018] Two guide rods 6 are fixed on the back corresponding to the protrusion in the middle of the core knife seat 2, and the two through holes on the upper and lower sides of the U-shaped fixing seat 3 are sleeved on the guide rods; they can be hung on the guide rods and slide; Wearing bearing pin 5, outer covering bearing 8;

[0019] The two holes of the connecting rod 4 use bearings 8, one bearing 8 is sleeved on the pin shaft 5, and the other bearing 8 is sleeved on the eccentric protrusion of the eccentric sleeve 7, and the protrusions of the pin shaft 5 and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap