Device and method for automatically removing oxygen and moisture from transition cabin of vacuum glove box

A vacuum glove box, transition cabin technology, applied in robotics, climate sustainability, final product manufacturing, etc., can solve problems such as shortening the life of the main box, rising oxygen and moisture content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

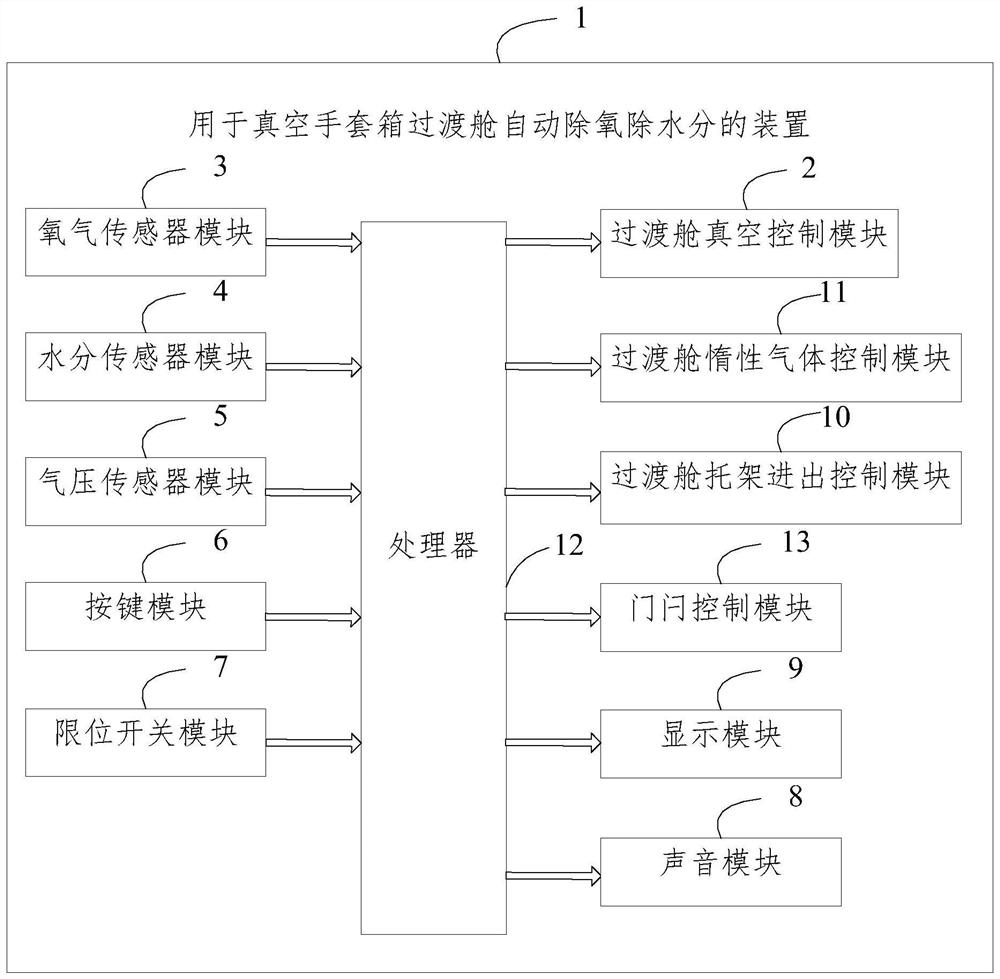

[0024] Please refer to figure 1 , a device 1 for automatic deoxygenation and moisture removal in a vacuum glove box transition chamber, comprising an oxygen sensor module 3, a moisture sensor module 4, an air pressure sensor module 5, a transition chamber vacuum control module 2, a transition chamber inert gas control module 11, and a transition chamber The carriage enters and exits the control module 10 and the processor 12;

[0025] The oxygen sensor module 3, moisture sensor module 4, air pressure sensor module 5, transition chamber inert gas control module 11, transition chamber vacuum control module 2 and transition chamber bracket entry and exit control module 10 are respectively electrically connected to the processor 12;

[0026] The oxygen sensor module 3, moisture sensor module 4 and air pressure sensor module 5 respectively collect data in the transition chamber and send them to the processor 12;

[0027] The processor 12 processes the received data, and sends corr...

Embodiment 2

[0041] The method for automatic deoxygenation and moisture removal in a transition chamber of a vacuum glove box comprises steps:

[0042] The oxygen sensor module, the moisture sensor module and the air pressure sensor module respectively collect the data in the transition chamber and send them to the processor;

[0043] The processor performs processing according to the received data, and sends corresponding instructions to control the working states of the transition chamber inert gas control module and the transition chamber vacuum control module.

[0044] The processor performs processing according to the received data, and sends corresponding instructions to control the working states of the transition chamber inert gas control module and the transition chamber vacuum control module as follows:

[0045] The processor judges whether the data is greater than a preset value according to the received data, and if so, sends an instruction to the transition chamber vacuum cont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap