Assembling and welding platform for pipelines

A technology for welding platforms and pipes, applied in the platform field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

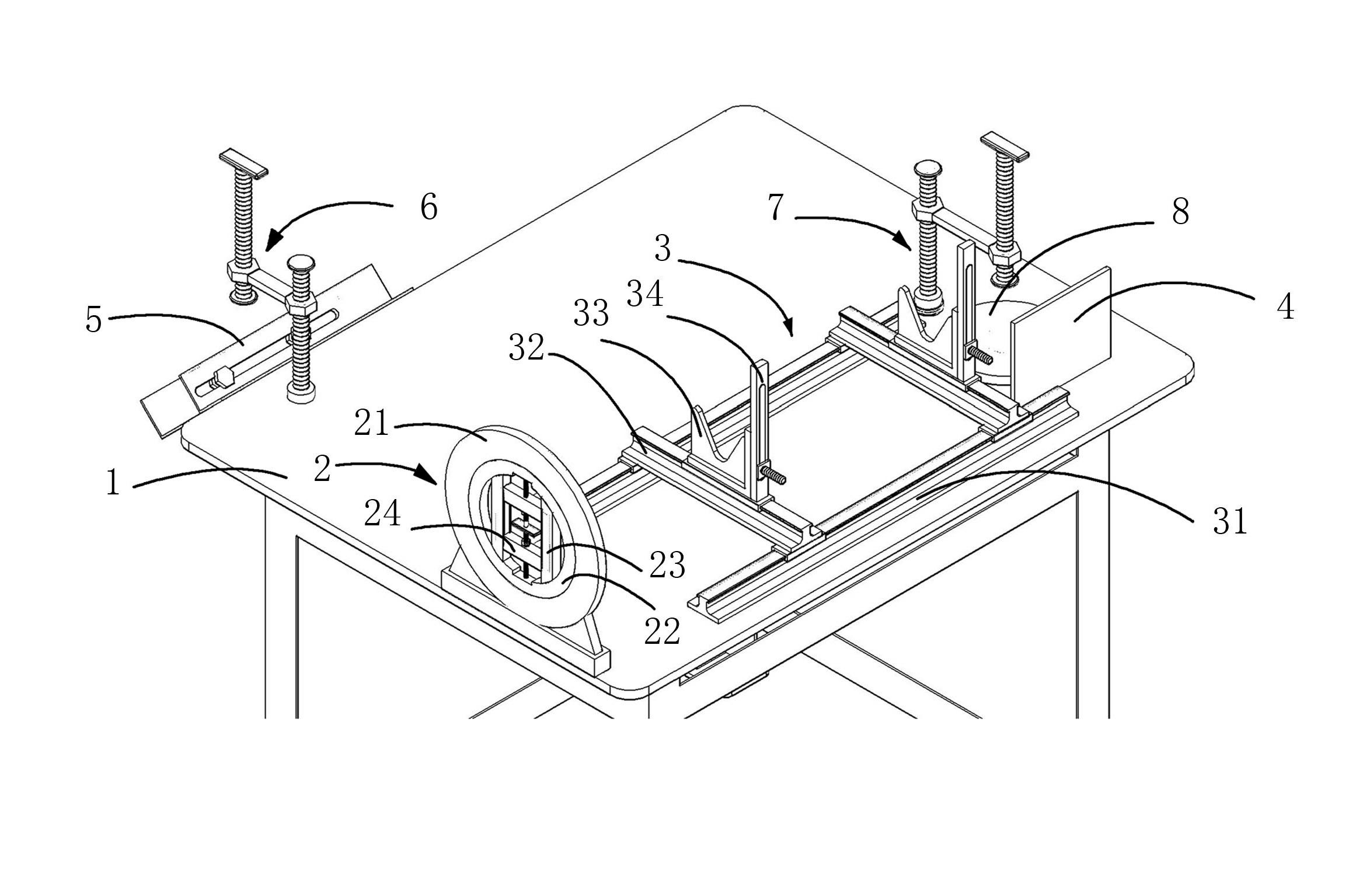

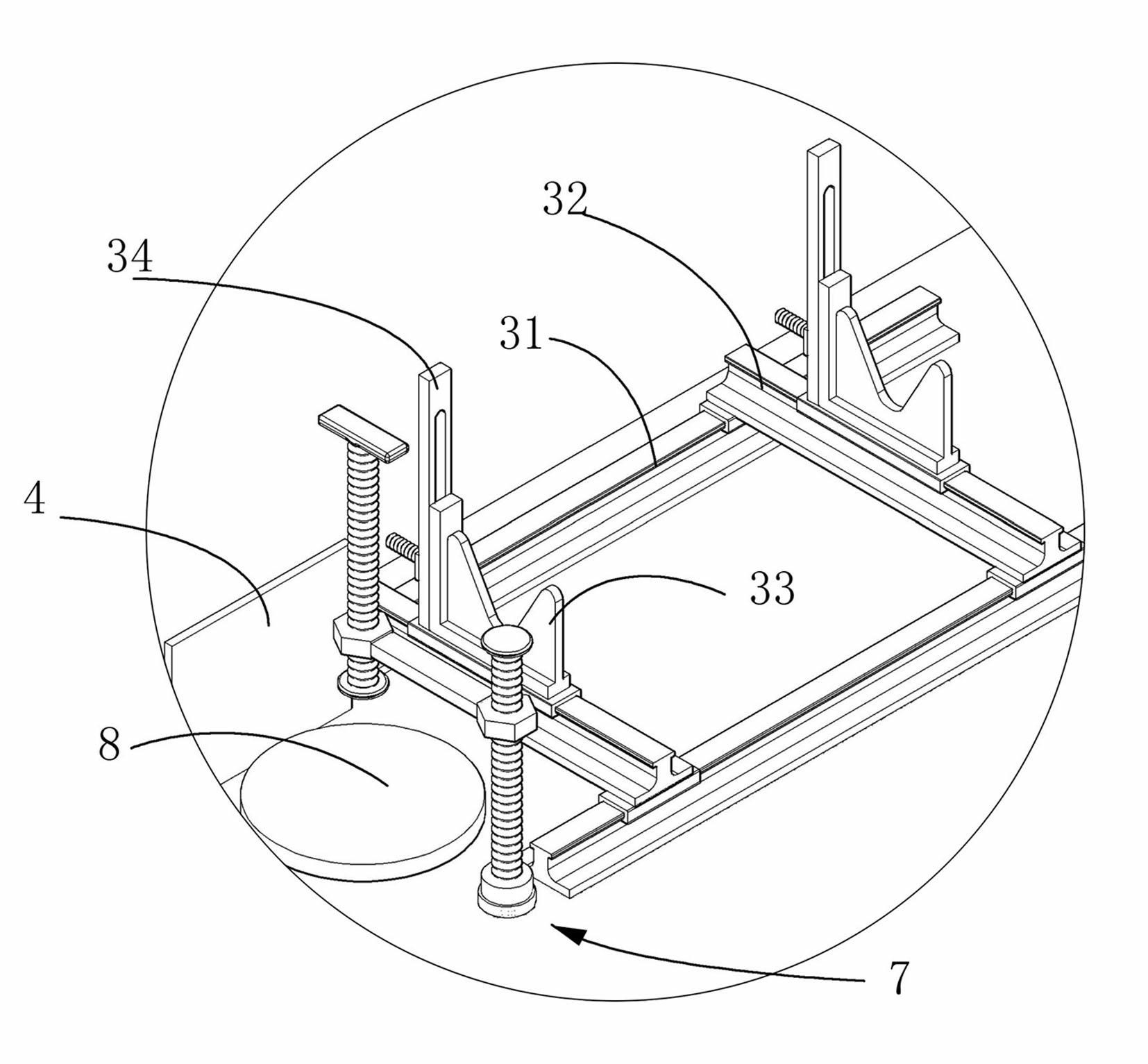

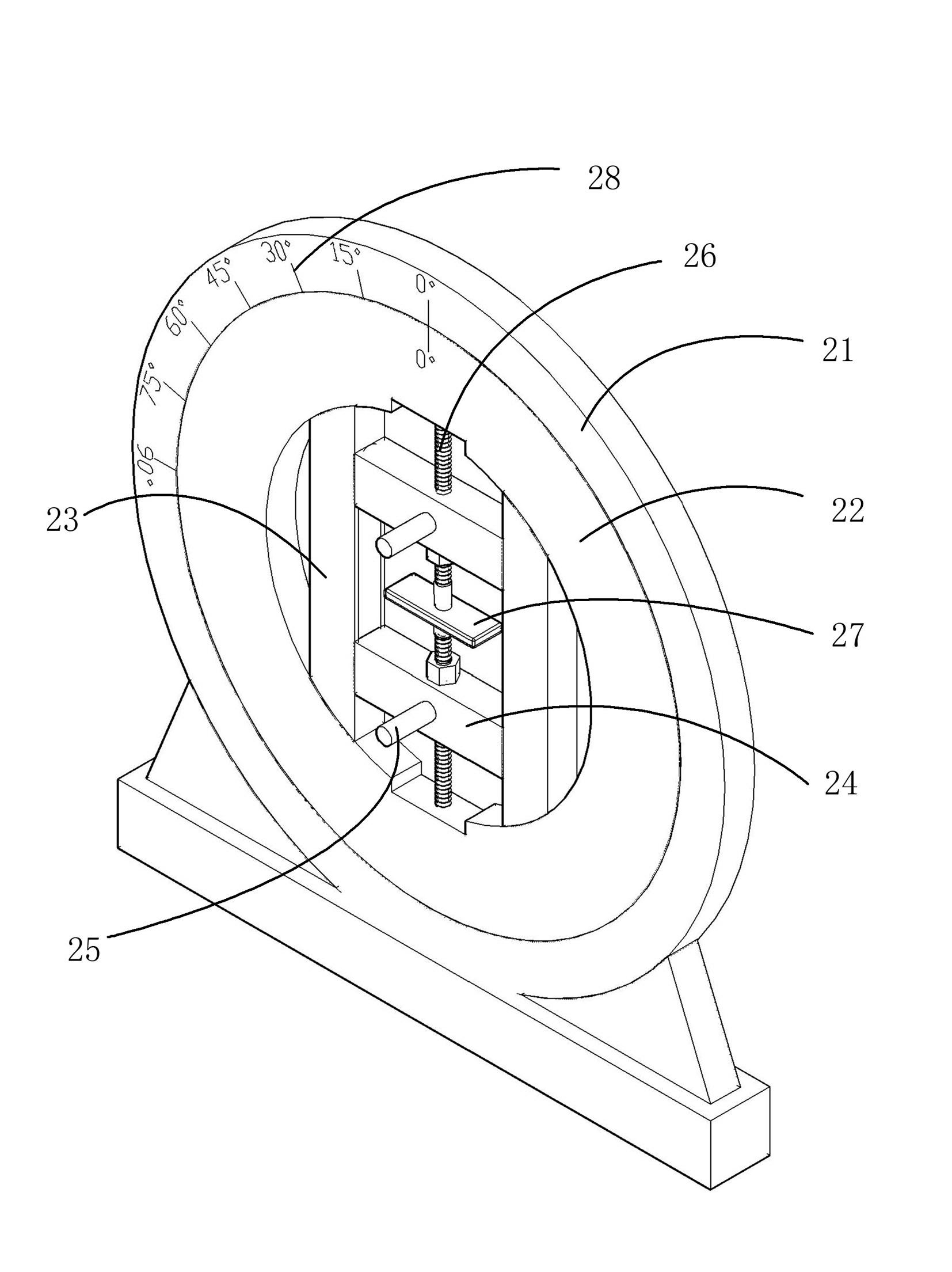

[0021] A pipeline assembly butt welding platform, such as figure 1 , figure 2 with image 3 As shown, it includes: a workbench; a flange placement device 2, the flange placement device 2 includes a fixed disk 21 and a moving disk 22 arranged concentrically, the fixed disk 21 is fixed on the workbench 1, and the moving disk 22 The upper rotation is installed on the fixed plate 21, and the supporting device for hanging the flange is installed on the said moving plate 22, and the scale 28 indicating the rotation angle of the moving plate 22 is provided on the said fixed plate 21; it is used to support A pipeline placement device 3 for the pipeline, the pipeline placement device 3 is installed on the workbench 1, and the pipeline placement device 3 supports the butt joint between the pipeline and the flange welding port.

[0022] The supporting device includes two parallel supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com