Reducing blasting weighting needle assembly

An assembly and blaster technology, which is applied in the field of variable-diameter blasting-type weighted needle assembly, can solve the problems of ineffective valve switch, small impact force, and high manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

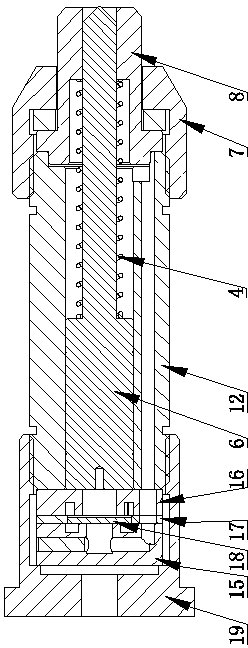

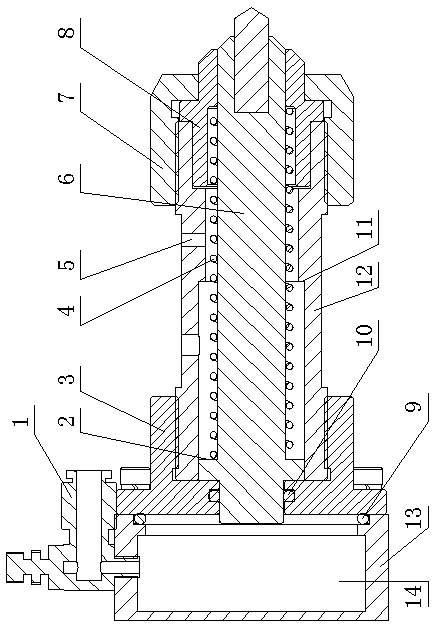

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

[0011] As shown in the accompanying drawings, a variable-diameter explosive weighted needle assembly includes a needle sleeve 12 with a pressure relief hole 5, a needle core 6 installed in the needle sleeve 12, and a return spring 4 is set on the needle core 6. The lower end of the needle core 6 and the front end of the return spring 4 are located in the guide tube 8, and the rear end of the guide tube 8 is located in the needle cover 12 and axially limited by the shoulder 11 in the needle cover 12. The needle cover 12 The front end of the needle sleeve 12 is threadedly connected with a front threaded sleeve 7, the rear end of the needle sheath 12 is threadedly connected with a rear threaded sleeve 3, and the rear end of the needle core 6 is provided with a shoulder 2, and the shoulder 2 can be connected with the rear Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap