Stack mold gripper

A gripper and grabbing unit technology, applied in the field of grabbing tools for stack mold products, can solve the problems of high cost, large number of manipulators or robots, etc., achieve the effect of short grabbing cycle, reliable grabbing, and reduced equipment capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

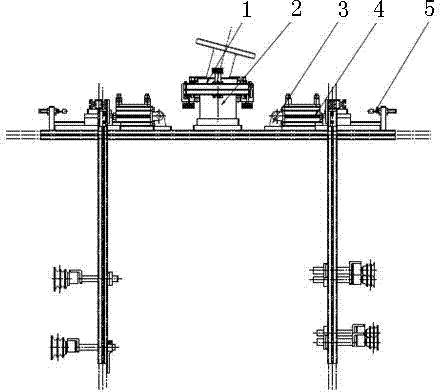

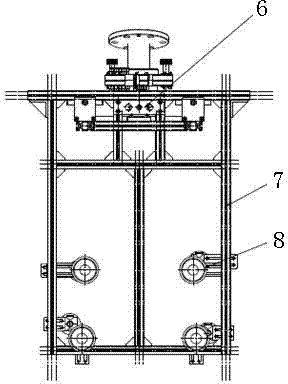

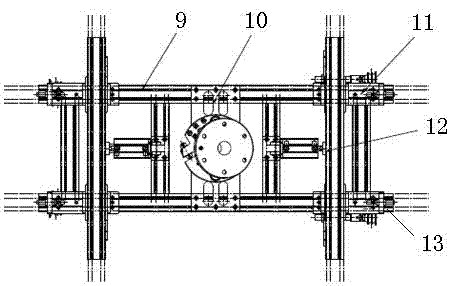

[0009] The grabbing unit support frame 7 is fixedly connected to the main frame 9, the transition connecting flange 2 is fixedly connected to the quick change device 1 through hexagon socket head screws, and connected to the gripper connecting plate 10, and the main frame 9 is connected to the gripper connecting plate through screws 10 is fixedly connected, the cylinder 4 is fixedly connected with the main frame 9 through the cylinder support 3, the front end of the piston push rod of the cylinder 4 is fixedly connected with the floating joint 12, the push plate 6 is fixedly connected with the grasping unit support frame 7, and the floating joint 12 is connected with the The push plate 6 is fixedly connected, the four slide rails 13 are fixedly connected to the main frame 9, the buffer device 5 is fixedly connected to one end of the slide rail 13, the slide block 11 is slidingly connected to the slide rail 13, and the four slide blocks 11 are supported by the grasping unit The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com