Scraper conveyor fault detection device, system and method

A scraper conveyor and detection device technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of long recovery process, shutdown, complex conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

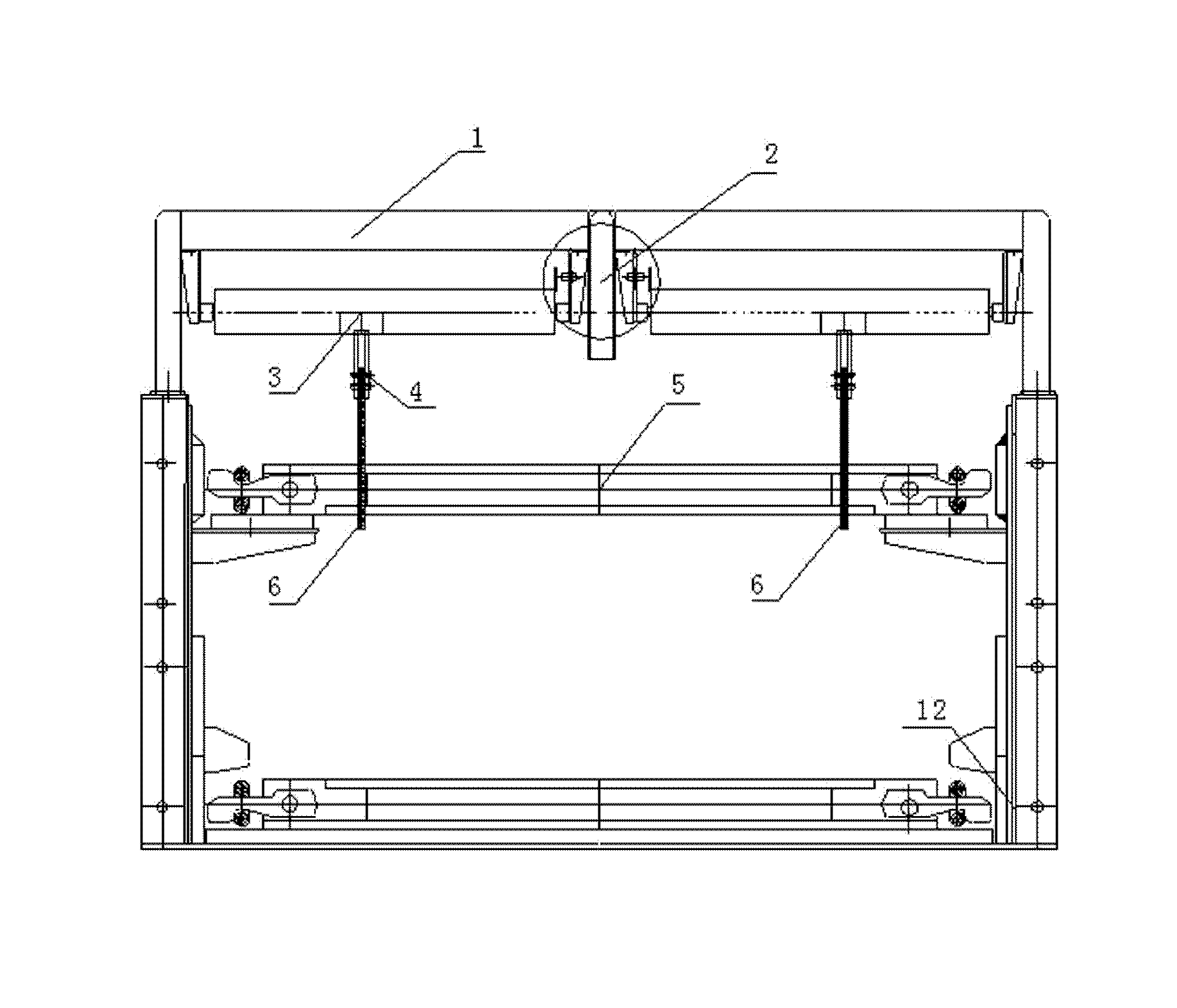

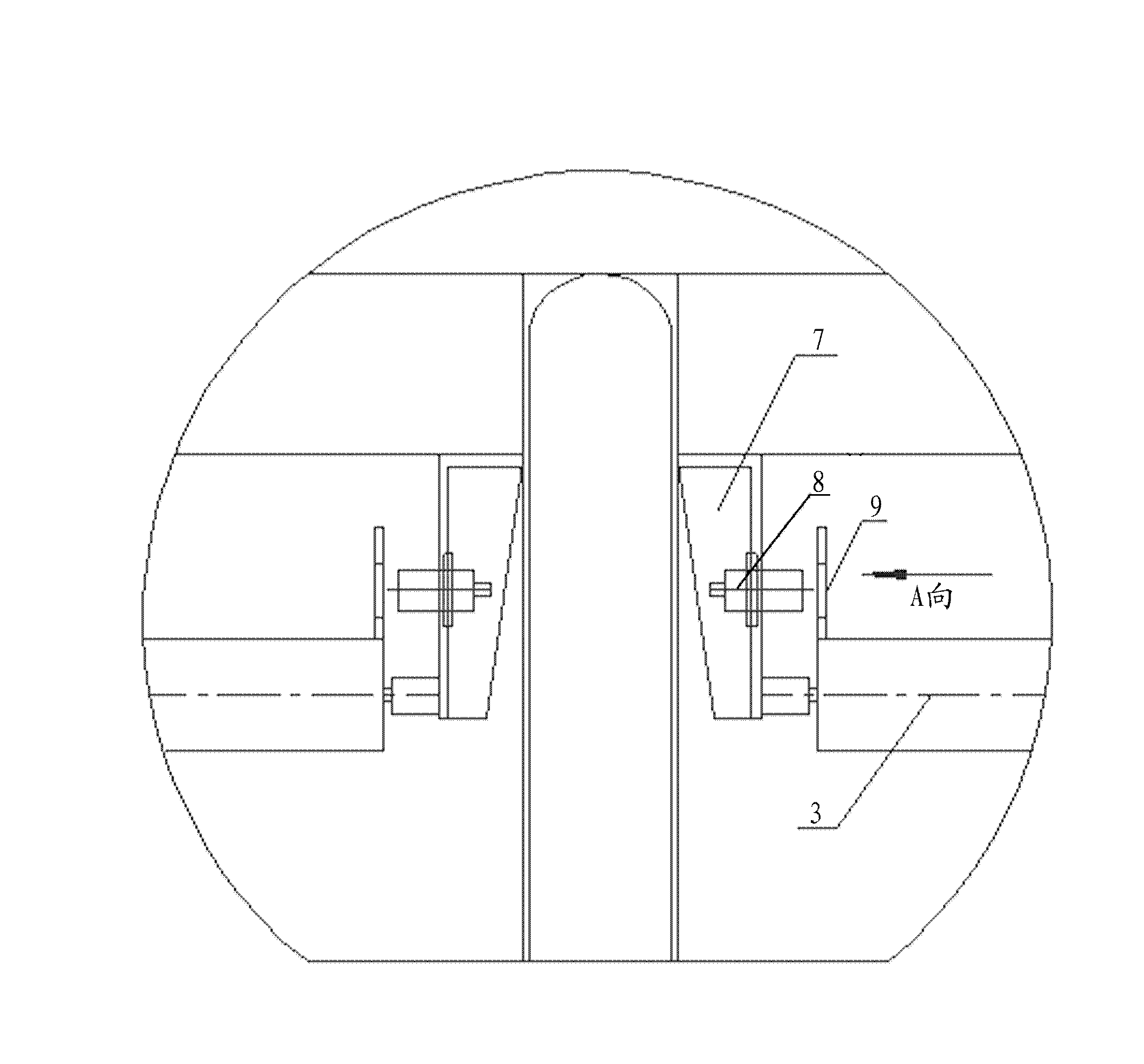

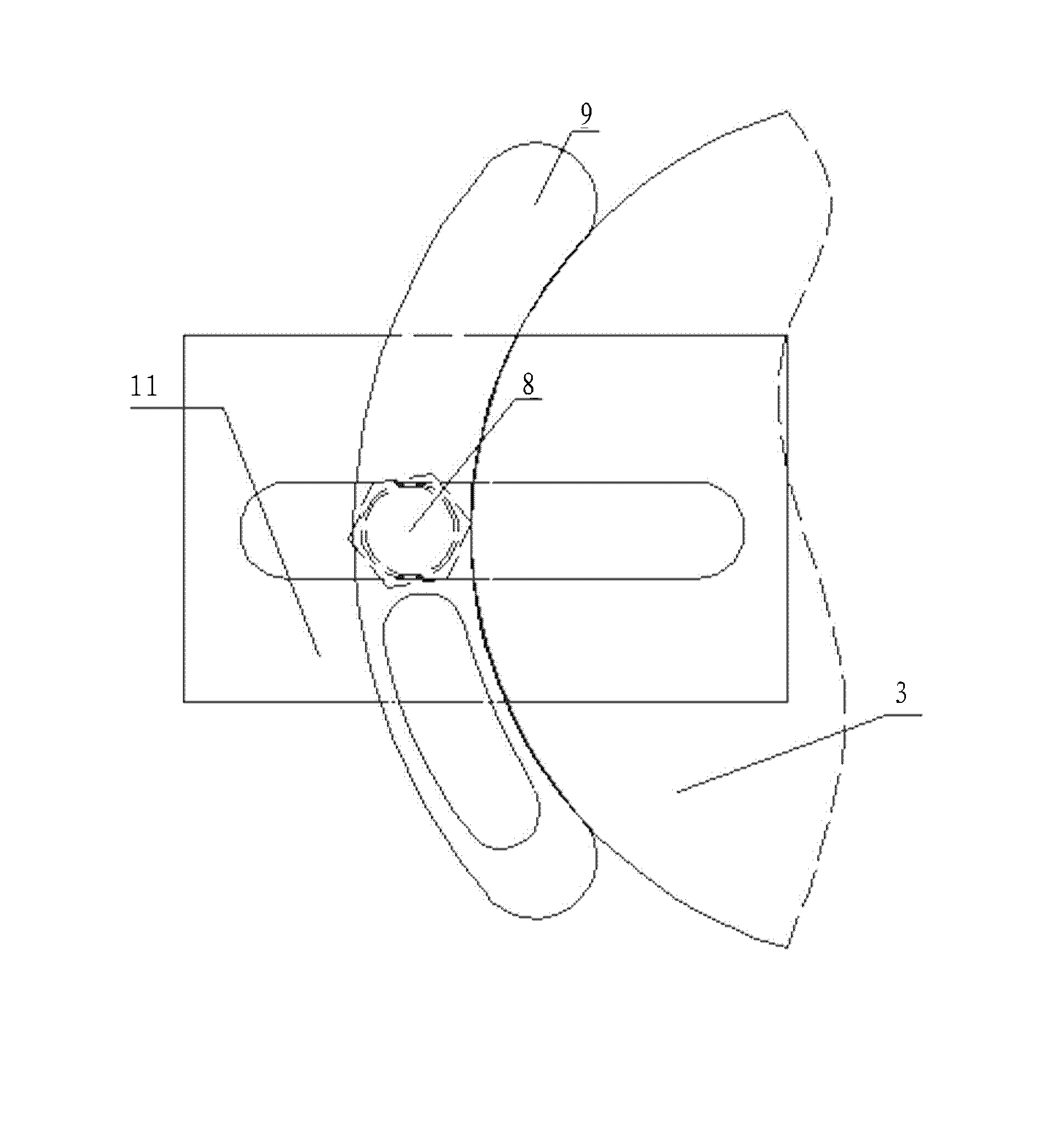

[0012] Embodiments of the present invention are described below with reference to the accompanying drawings. figure 1 It is a composition and installation position diagram of a detection device according to an embodiment of the present invention. As shown in the figure, the detection device mainly includes a frame assembly 1, a signal processing device 2, two idler rollers 3 and two actuating swing rods 6 (referred to as swing rod A and swing rod B respectively). The frame assembly 1 is used to directly or indirectly carry various components. The two idlers 3 are arranged on the frame assembly 1 and can rotate independently around two corresponding horizontal rotation axes. The two horizontal axes of rotation involved lie on the same horizontal line. The two touch rockers are vertically and rigidly connected to the two rollers 3 respectively. Preferably, the two actuating swing rods are respectively placed at both ends of the corresponding idler rollers away from each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com