Calcium-magnesium compound fertilizer, and preparation method and application method thereof

A compound fertilizer, calcium and magnesium technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of insufficient attention to the demand of calcium and magnesium in crops, insufficient amount of chelated magnesium, etc., to improve the storage period, meet the needs of nutrition, The effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

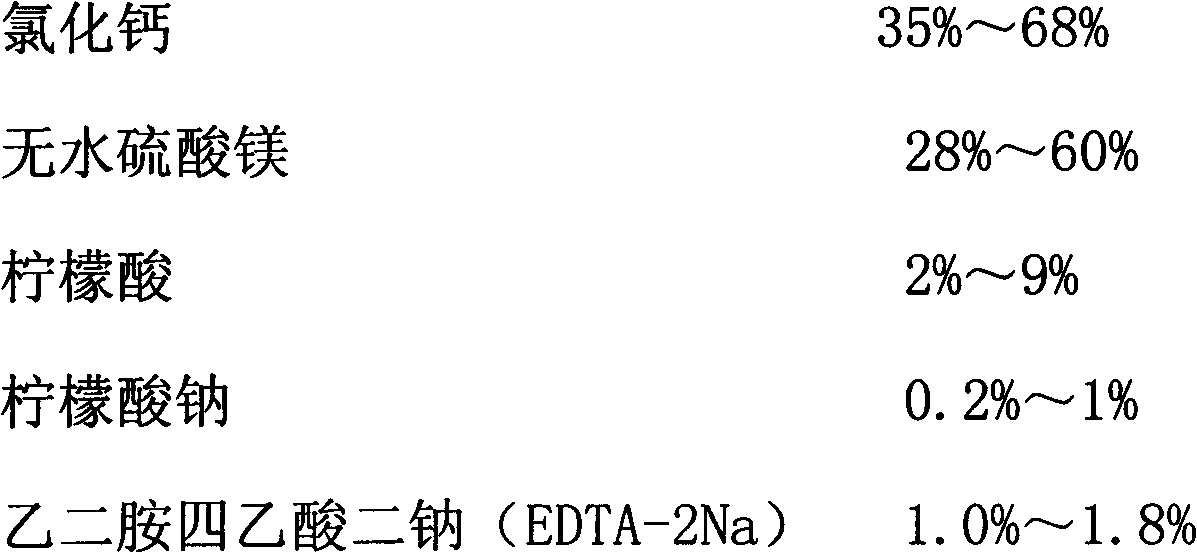

[0034] A calcium-magnesium compound fertilizer, which is made from raw materials comprising the following percentages by weight:

[0035]

[0036] The preparation method of above-mentioned calcium-magnesium compound fertilizer, it comprises the following steps:

[0037] (1) Calcium chloride, anhydrous magnesium sulfate, citric acid, sodium citrate, disodium edetate are weighed in proportion;

[0038] (2) Grinding the raw material in step (1) into small particles with a grinder, and crossing 40 mesh sieves;

[0039] (3) After grinding, add calcium chloride, anhydrous magnesium sulfate, and disodium ethylenediamine tetraacetate into the mixer according to the set ratio for stirring. The temperature is controlled at 115 degrees Fahrenheit, stirring for 15 minutes, and then dissolved until the proportion of distilled water;

[0040] (4) Add citric acid and sodium citrate to the mixture obtained in step (3), then pour it into a W double-cone mixer and stir for 12 minutes. Duri...

Embodiment 2

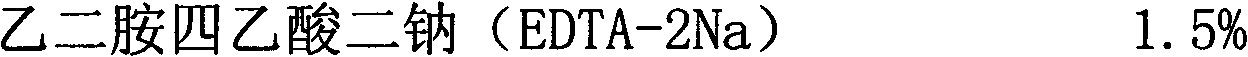

[0049] A calcium-magnesium compound fertilizer is made from raw materials comprising the following percentages by weight:

[0050]

[0051] The preparation method of above-mentioned calcium-magnesium compound fertilizer, it comprises the following steps:

[0052] (1) Calcium chloride, anhydrous magnesium sulfate, citric acid, sodium citrate, disodium edetate are weighed in proportion;

[0053] (2) Grinding the raw material in step (1) into small particles with a grinder, and crossing 40 mesh sieves;

[0054] (3) After grinding, add calcium chloride, anhydrous magnesium sulfate, and disodium ethylenediaminetetraacetate into the blender according to the set ratio for stirring, control the temperature at 120 degrees Fahrenheit, stir for 15 minutes, and then dissolve until the proportion of distilled water;

[0055] (4) Add citric acid and sodium citrate to the mixture obtained in step (3), then pour it into a W double-cone mixer and stir for 12 minutes. During the stirring p...

Embodiment 3

[0060] A calcium-magnesium compound fertilizer is made from raw materials comprising the following percentages by weight:

[0061]

[0062] The preparation method of above-mentioned calcium-magnesium compound fertilizer, it comprises the following steps:

[0063] (1) Calcium chloride, anhydrous magnesium sulfate, citric acid, sodium citrate, disodium edetate are weighed in proportion;

[0064] (2) Grinding the raw material in step (1) into small particles with a grinder, and crossing 40 mesh sieves;

[0065] (3) After grinding, add calcium chloride, anhydrous magnesium sulfate, and disodium ethylenediamine tetraacetate into the mixer according to the set ratio for stirring. The temperature is controlled at 135 degrees Fahrenheit, stirring for 15 minutes, and then dissolved until the proportion of distilled water;

[0066](4) Add citric acid and sodium citrate to the mixture obtained in step (3), then pour it into a W double-cone mixer and stir for 12 minutes. During the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap