Method for improving purification of aliphatic acids in petroleum geology sample

A technology for geological samples and fatty acids, applied in chemical instruments and methods, preparation of carboxylates, preparation of organic compounds, etc., can solve problems such as utilization of geochemical information affecting authenticity, discarding of transition phases, loss, etc., to improve accuracy effectiveness and authenticity, optimizing technical solutions, and avoiding loss rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

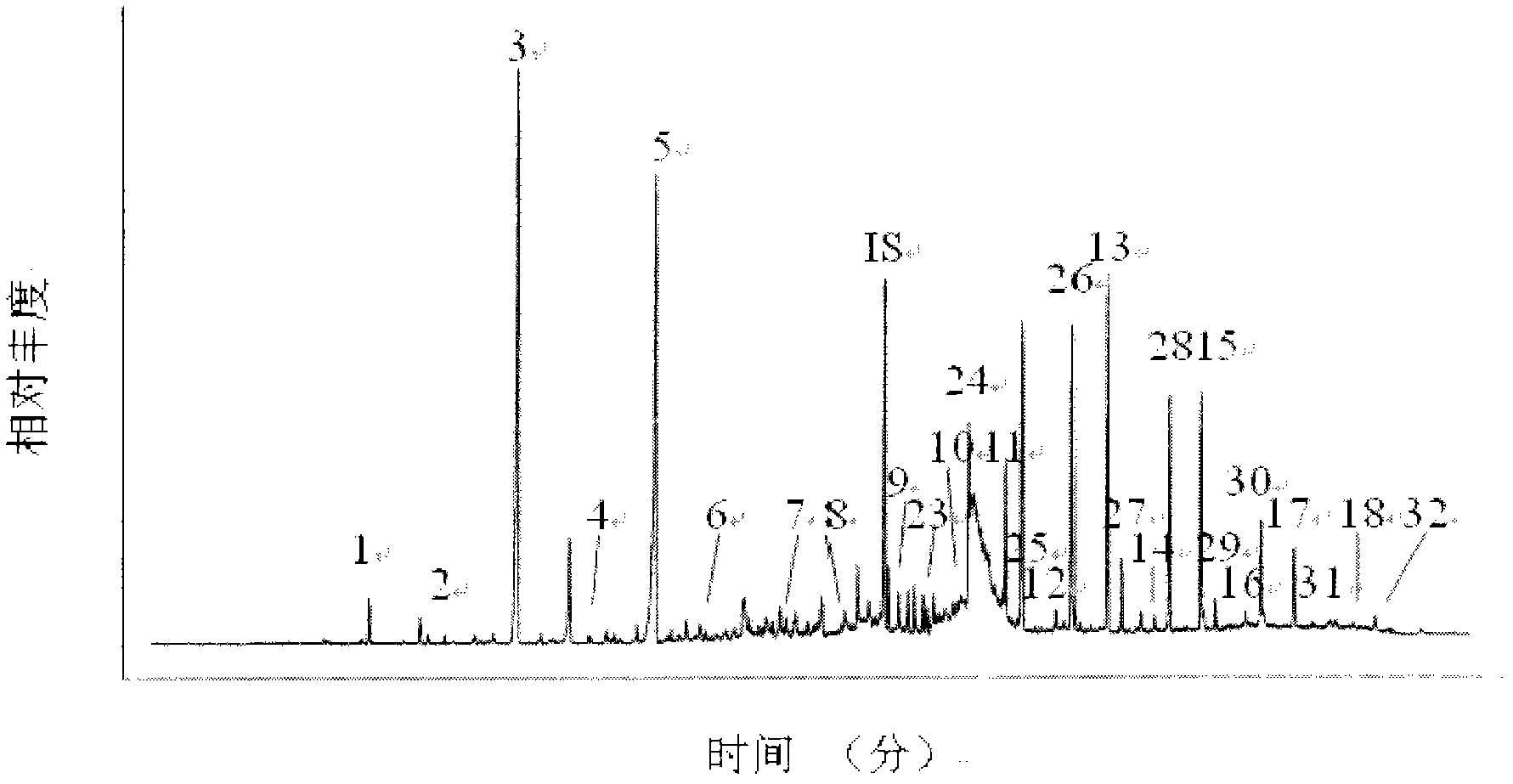

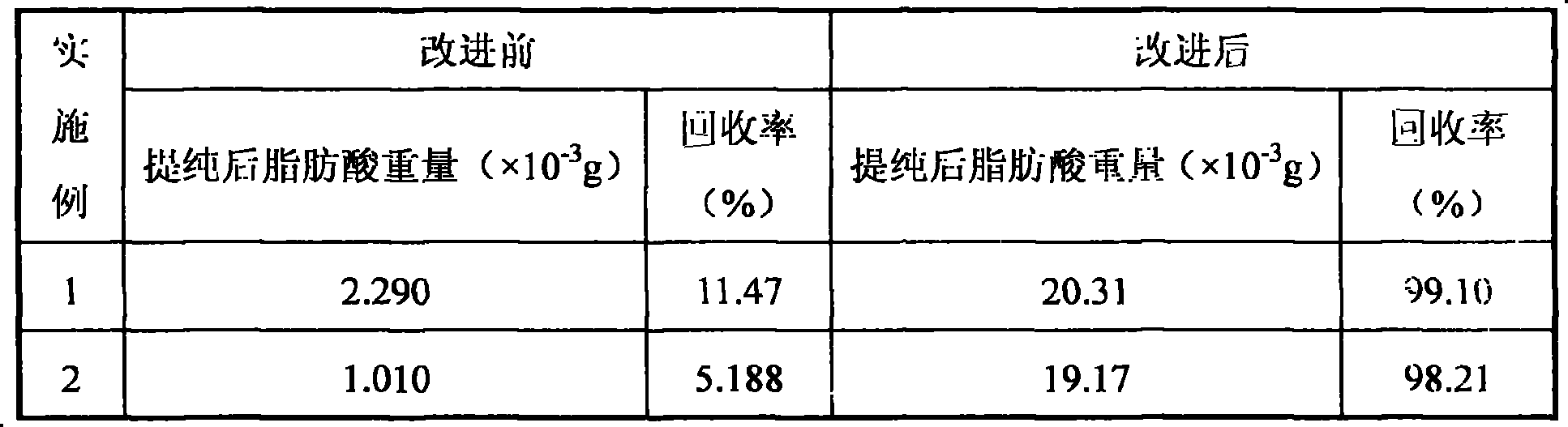

Embodiment 1

[0047] The improved method of purifying fatty acid in the petroleum geological sample of embodiment 1 comprises the following steps:

[0048] (1) Crushing the petroleum geological sample to 100-200 mesh to obtain geological sample powder.

[0049] (2) Add 20ml of organic solvent—chloroform to 10g of geological sample powder, and perform ultrasonic extraction at room temperature at a frequency of 20kHz for 20min, three times in total. After the extracts were combined, they were concentrated in a water bath at 70-80°C to obtain 10ml of total geological lipids.

[0050] (3) Add an alcohol-alkali solution of 1 times its volume to the total geological lipid, heat at 70°C, stir, condense and reflux for 4-5 hours to obtain 20ml of saponified solution.

[0051] (4) Add an equal volume of organic solvent—chloroform to the saponification solution, and carry out liquid-liquid extraction in a 125ml pear-shaped separating funnel, and each time there are aqueous phase, transition phase and...

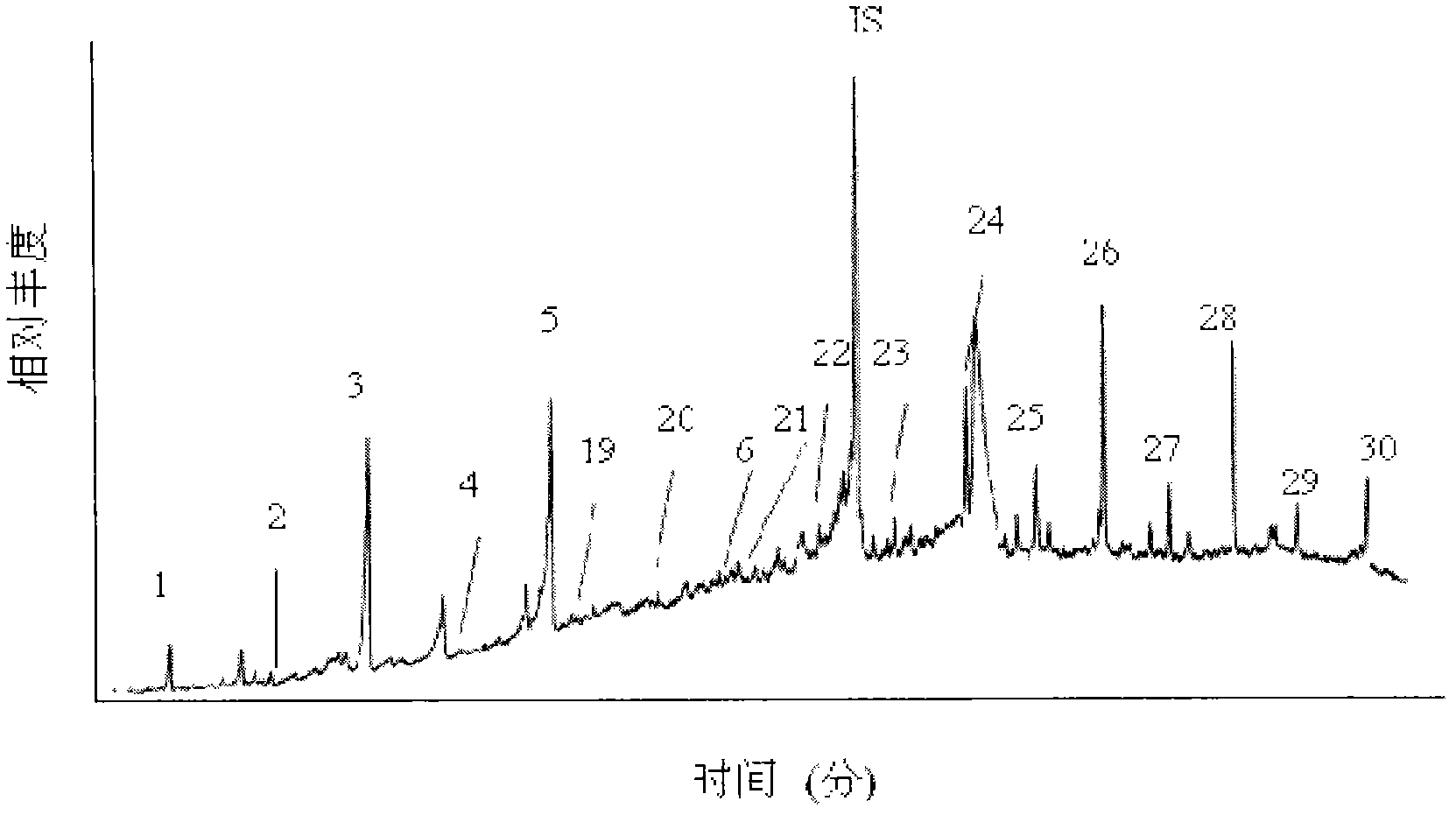

Embodiment 2

[0055] The improved method of purifying fatty acid in the petroleum geological sample of embodiment 2 comprises the following steps:

[0056] (1) Crushing the petroleum geological sample to 100-200 mesh to obtain geological sample powder.

[0057] (2) Add 50ml of organic solvent—chloroform to 10g of geological sample powder, carry out Soxhlet extraction for 72 hours in a water bath at 70-80°C, and concentrate in a water bath at 70°C to obtain 10ml of total geological lipids.

[0058] (3) Add an alcohol-alkali solution twice its volume to the total geological lipid, heat at 80°C, stir, condense and reflux for 4-5 hours to obtain 30ml of saponified liquid.

[0059] (4) Add an equal volume of organic solvent—n-hexane in the saponification solution, and carry out liquid-liquid extraction in a pear-shaped separating funnel of 125ml. Aqueous phase, transition phase and organic phase appear in each system; extract until no longer until the transition phase occurs.

[0060] (5) Sepa...

Embodiment 3

[0063] The improved method of purifying fatty acid in the petroleum geological sample of embodiment 3 comprises the following steps:

[0064] (1) Crushing the petroleum geological sample to 100-200 mesh to obtain geological sample powder.

[0065] (2) Add 50ml of organic solvent—dichloromethane to 10g of geological sample powder, carry out Soxhlet extraction for 72 hours in a water bath at 40-50°C, and concentrate in a water bath at 40°C to obtain 10ml of total geological lipids things.

[0066] (3) Add an alcohol-alkali solution twice its volume to the total geological lipid, heat at 75°C, stir, condense and reflux for 4-5 hours to obtain 30ml of saponified liquid.

[0067] (4) Add an equal volume of organic solvent—methylene chloride in the saponification liquid, carry out liquid-liquid extraction in a pear-shaped separating funnel of 125ml, and water phase, transition phase and organic phase all appear in each system; until the transition phase occurs.

[0068] (5) Separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com