Production method of yellow rice wine rich in reduced glutathione, and produced yellow rice wine

A technology for glutathione and a production method, which is applied in the fields of comprehensive utilization of fermentation and fermentation and brewing, can solve the problems of unimproved energy conservation and environmental protection, increase of gout in the middle-aged and elderly, and no innovation in the process, and is suitable for large-scale promotion. Application, overall efficiency improvement, clever design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Waste yellow rice wine yeast was obtained by separating waste yellow rice wine grains, adding 5% yeast extract broth (YE) medium, liquid-state fermentation for 72 hours, extraction by hot water-concentration under reduced pressure-salt precipitation-ethanol extraction-concentration under reduced pressure-to obtain The sample liquid with good orange-yellow fluidity-concentrated and dried to obtain the reduced glutathione extract, wherein the hot water temperature is 70°C, the reduced pressure is 5KPa, NaCl is precipitated, and the drying temperature is 75°C; after HPLC (high pressure liquid phase Chromatography) detects that the reduced glutathione content in the obtained reduced glutathione extract is >95%, and the impurities are mainly sugar and protein.

Embodiment 2

[0029] Separation of waste rice wine yeast from waste rice wine grains, without liquid post-fermentation, directly through hot water extraction-decompression concentration-salt precipitation-partition chromatography-decompression concentration-to obtain an orange-yellow sample liquid with good fluidity- Concentrate and dry to obtain the reduced glutathione extract, in which macroporous adsorption resins (Tianjin Bohong, D3520, D4006, D4020) are used for partition chromatography, in which the hot water temperature is 100 °C, the reduced pressure is 0.5KPa, NaCl The temperature of precipitation and drying is 60°C; the content of reduced glutathione in the obtained reduced glutathione extract detected by HPLC (high pressure liquid chromatography) is >95%, and the impurities are mainly sugar and protein.

Embodiment 3

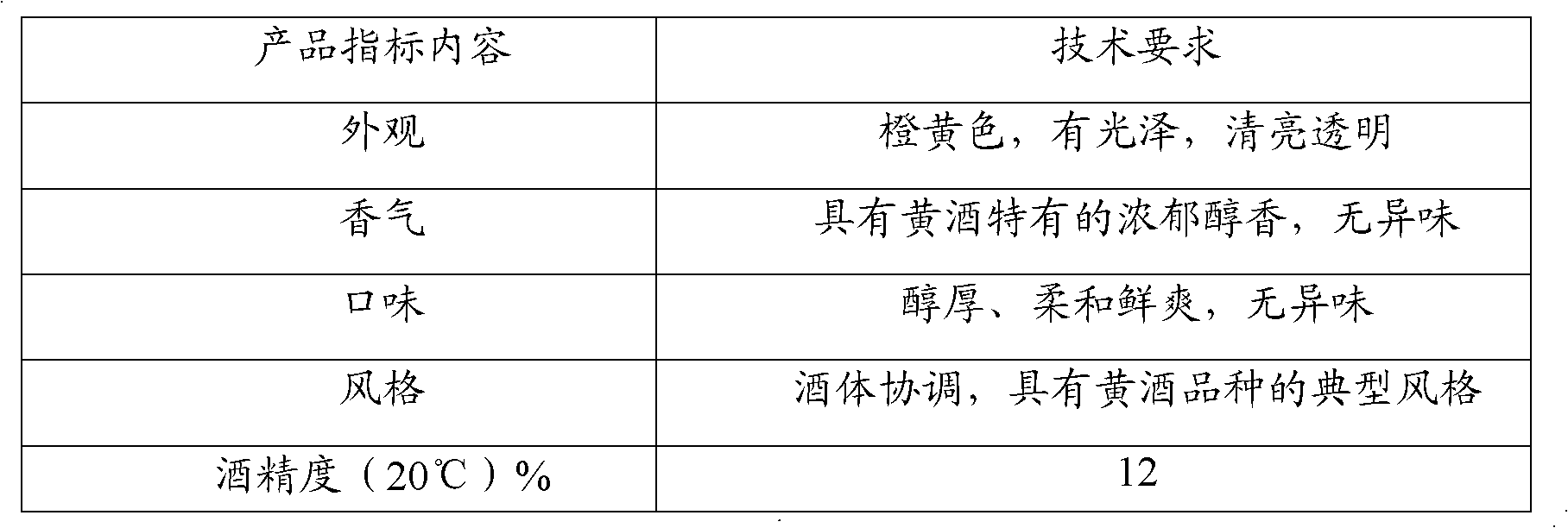

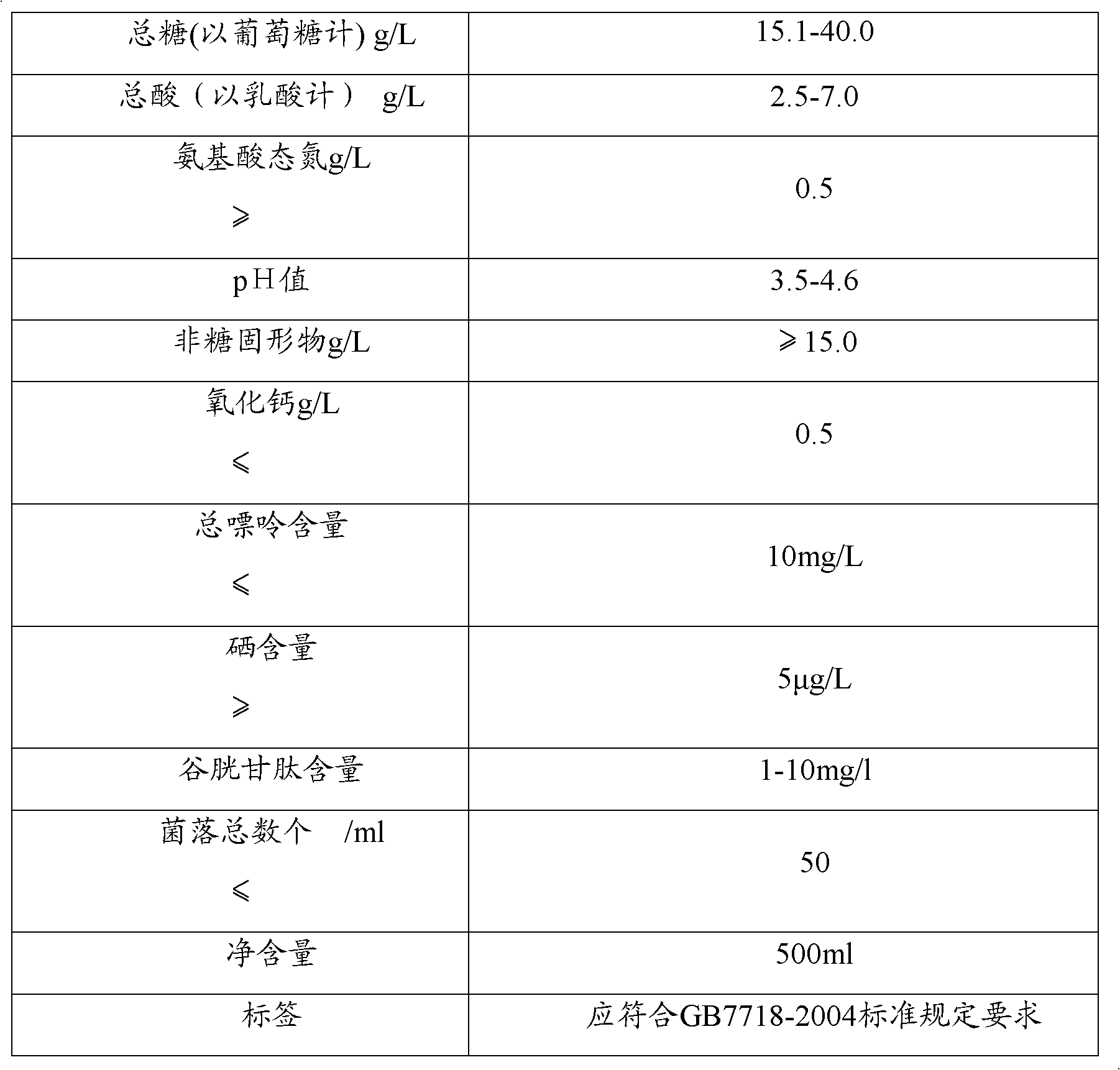

[0031] 500g rice, add koji (Nantong Baipu Yellow Wine Co., Ltd., the same below) 5%, water is mineral water rich in selenium (provided by Nantong Baipu Yellow Wine Co., Ltd., the same below), selenium content 10-50μg / L, pre-fermentation After 14 days, transfer to the post-fermentation stage, receive 1% of wine medicine (Nantong Baipu Yellow Wine Co., Ltd., the same below), after 7 days of fermentation, divide into two parts, and add the 0.01% reduced form prepared in Example 1 and Example 2 respectively The glutathione extract is fermented, decocted and aged to obtain the finished wine. The content of reduced glutathione is 1.2 mg / l and the selenium content is 5 μg / L as detected by HPLC, and the taste is refreshing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com