Nanometer strengthening method of surface of long thin piston rod of hydraulic oil cylinder

A technology of hydraulic oil cylinder and piston rod, which is applied in the field of nano-strengthening the surface of the slender piston rod of hydraulic oil cylinder, can solve problems such as technical limitations, and achieve the effects of improving work efficiency, high efficiency, and easy guarantee of travel tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

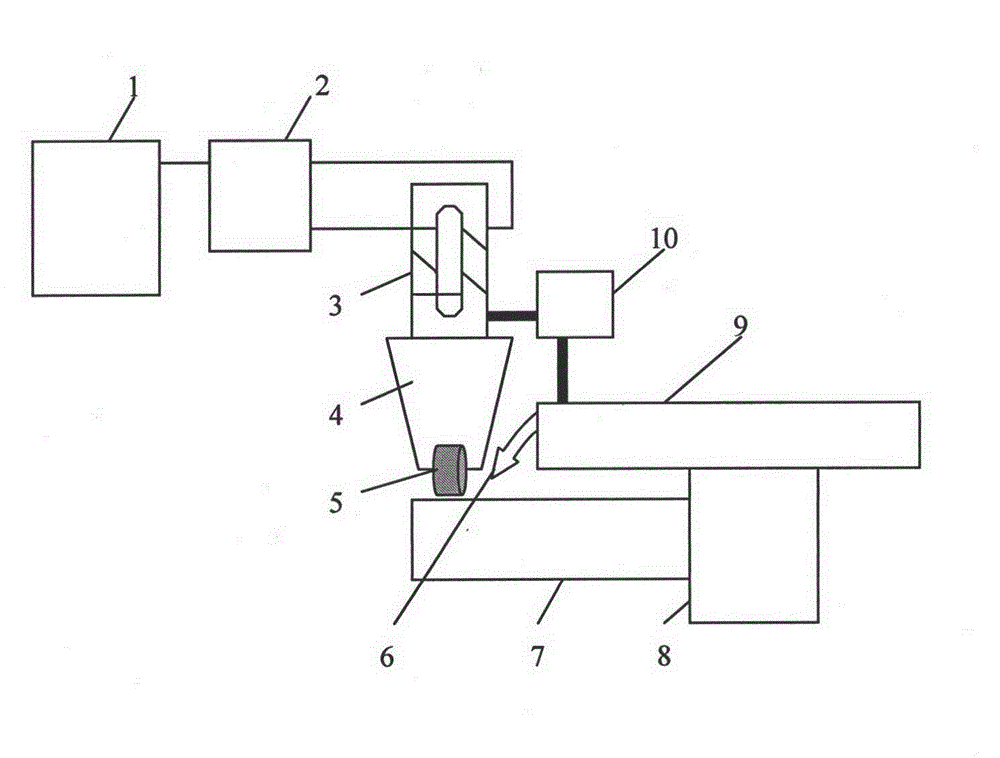

[0023] Such as figure 1 As shown, the ultrasonic nano-strengthening system is mainly composed of an ultrasonic module and a machine tool module connected in sequence. Among them, the ultrasonic module is composed of a controller 1, an ultrasonic generator 2, a transducer 3, a horn 4, and a ball 5. The machine tool module is composed of fuel injection pipe 6 , slender piston rod 7 , fixture 8 , horizontal lathe 9 and tool rest 10 . The parameters of the ultrasonic wave in the process of nanostrengthening are adjusted by the controller 1 and monitored in real time; the ultrasonic generator 2 is used to generate an alternating voltage at a frequency of 30KHz; the transducer 3 converts the 30KHz alternating voltage into ultrasonic vibration; The vibration amplitude is amplified; the ball 5 is driven to vibrate at high frequency, and the ball 5 interacts w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com