Pull-up ladder stand

A technology for climbing ladders and locking mechanisms, applied in ladders, buildings, building structures, etc., can solve the problems of small hoistway size, people falling into the bottom pit and other problems, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

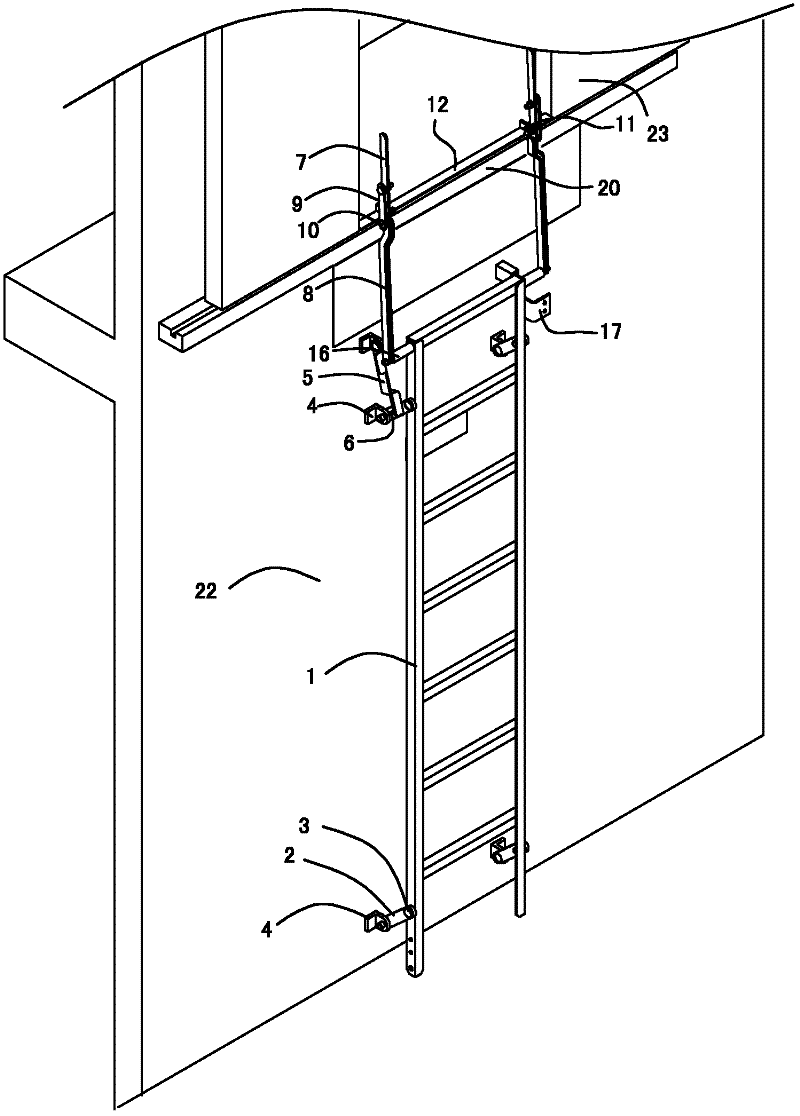

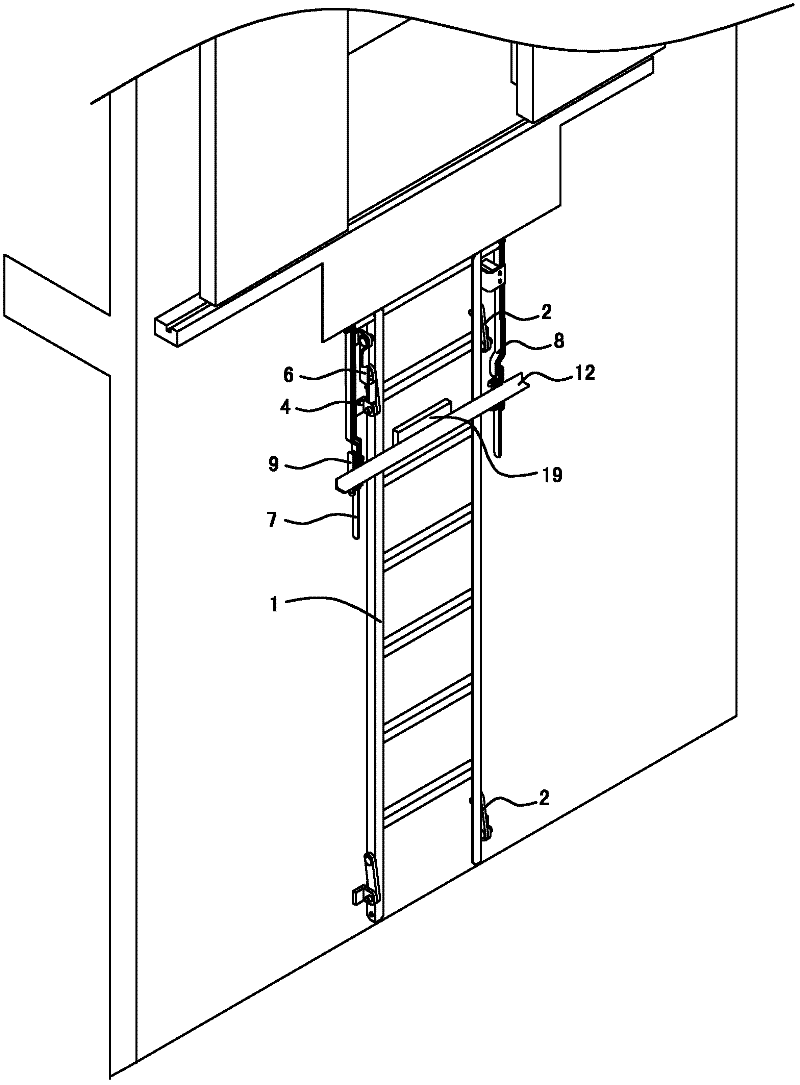

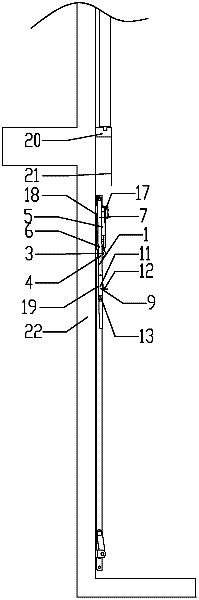

[0041] Such as Figure 1 to Figure 4 As shown, the pulling ladder of the present invention includes: a ladder body 1, at least one pair of connecting mechanisms and at least one first locking mechanism 5 respectively arranged on both sides of the ladder body 1, one end of the connecting mechanism and The ladder body 1 is rotatably connected, the other end of the connecting mechanism is rotatably connected to the well wall 22, one end of the first locking mechanism 5 is connected and fixed to the well wall 22, and the other end of the first locking mechanism 5 is connected to the well wall 22. The above-mentioned connecting mechanism is clamped or is in a free state.

[0042] Through the cooperation of the connecting mechanism and the first locking mechanism 5, the pull-type ladder can have two states of opening and retracting. state), it can stick to the hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com