Directly-operated type two-position four-way solenoid valve

A two-position, four-way, solenoid valve technology, applied in the field of solenoid valves, can solve the problems that water, gas, and oil media cannot be used universally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

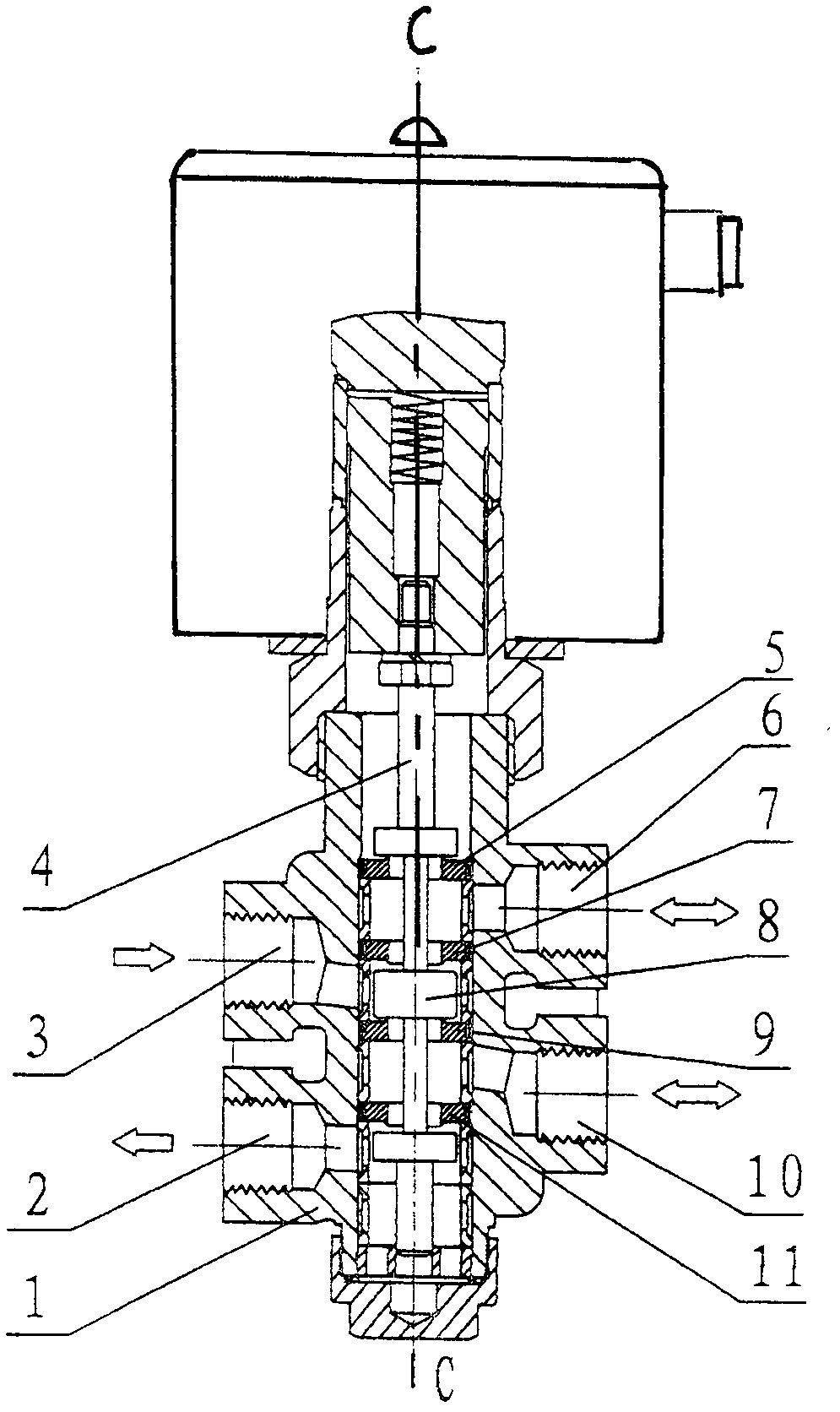

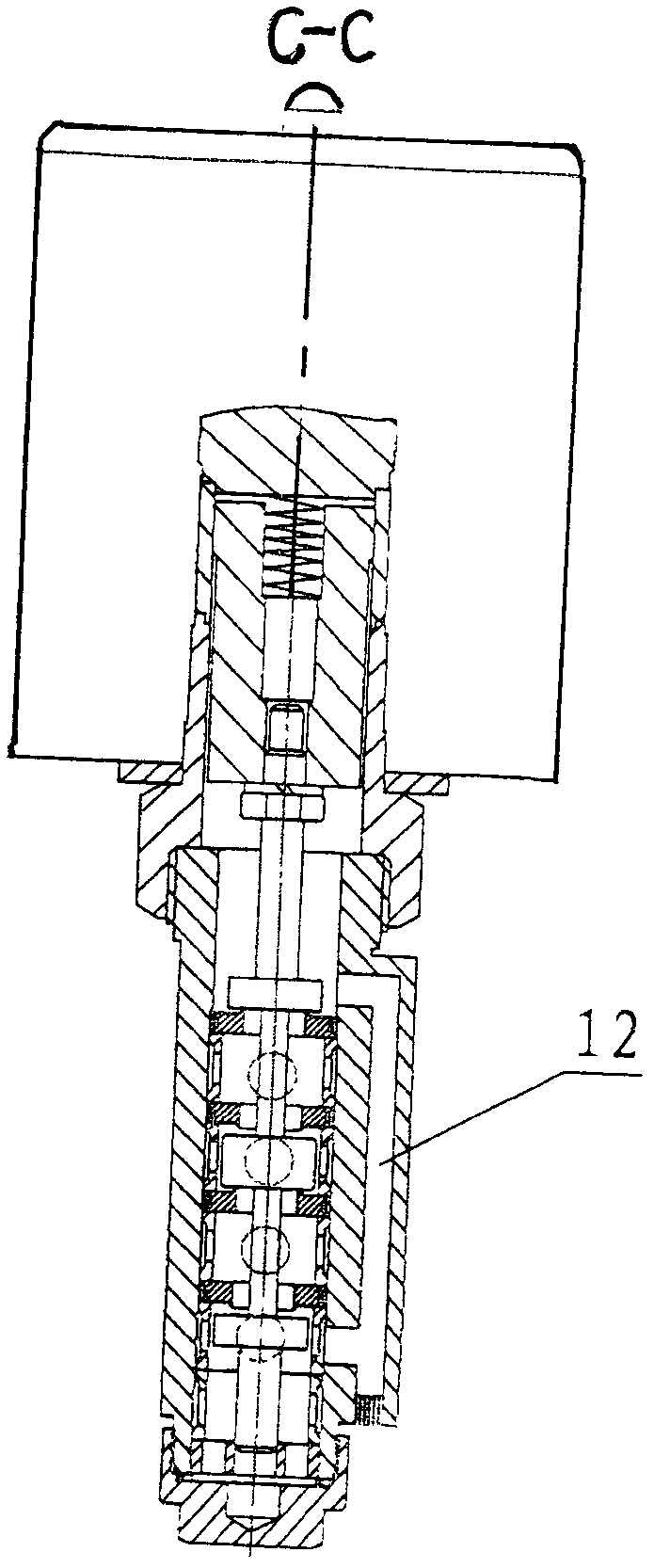

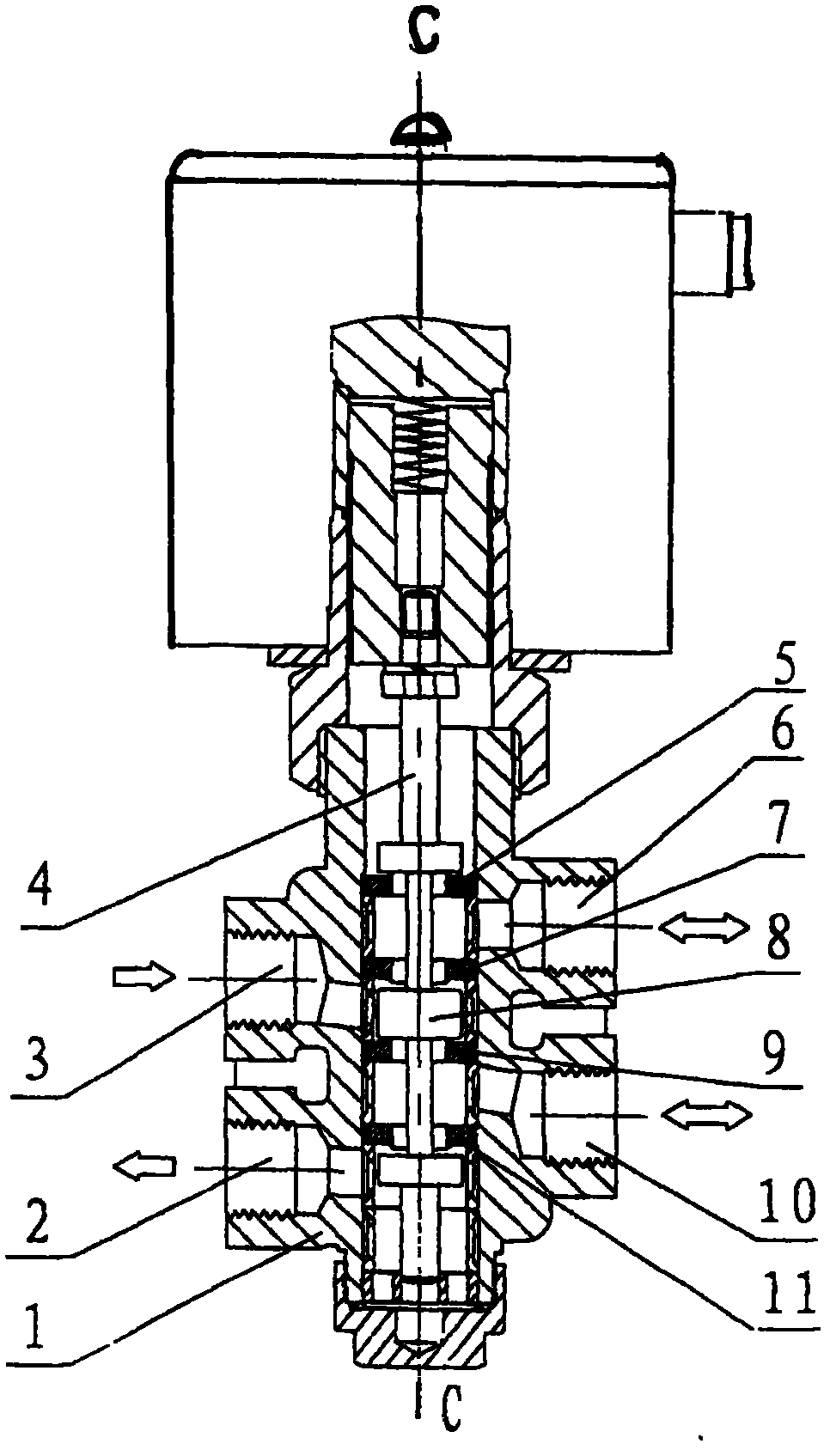

[0014] The direct-acting two-position four-way solenoid valve adopts a pressure-balanced sealing structure and includes a valve body 1, four valve seats 5, 7, 9, 11, and a valve stem assembly 4. The valve body 1 is provided with four medium circulation channels 12, which connect the uppermost port 6 and the lowermost port 2 (see figure 2 ), its port 2 is the medium drain port. The valve body is provided with four valve seats 11, 7, 5, 9 corresponding to the four ports 2, 3, 6, 10, and a valve plug assembly 8 mounted on the valve stem by four valve plugs and four valves Seats 5, 7, 9, and 11 form a sealing surface to form a valve body-connected sealing structure. Port 6 and port 2 are connected through the medium passage 12, so that no matter which medium enters from port 3, 6, 10, the valve can be made The rod assembly 4 is a group of continuous transport systems that are not affected by the force of the medium, but are only affected by spring force, gravity and electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com