High pressure helium charging device for aerostat

An aerostat and high-pressure technology, applied in the field of high-pressure helium filling devices, can solve the problems of slow helium filling speed and large diameter of transmission hose, and achieve the effects of improving helium filling speed, good versatility and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

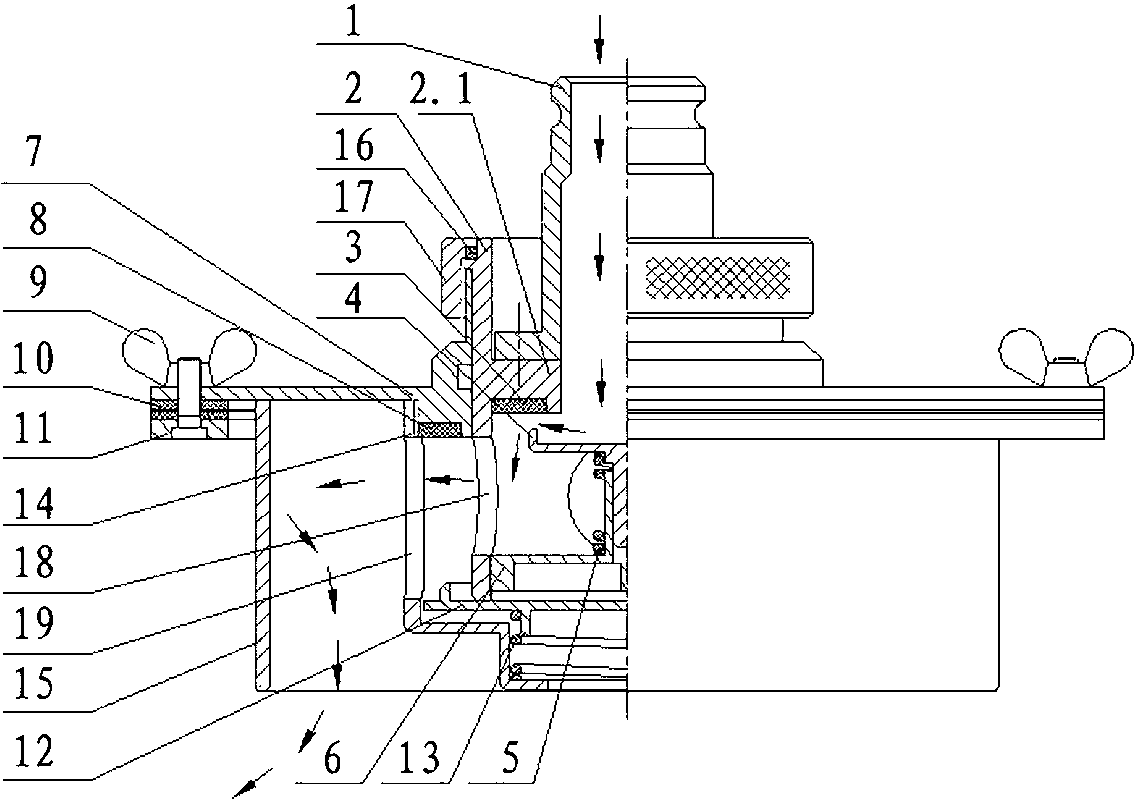

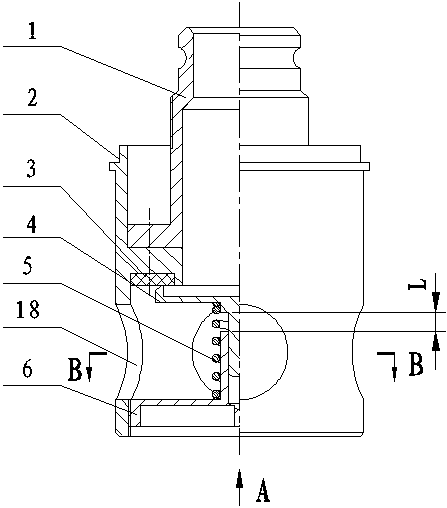

[0030] see figure 1 , The high-pressure helium filling device for the aerostat includes a decompression mechanism and an air-filling and diffusion mechanism.

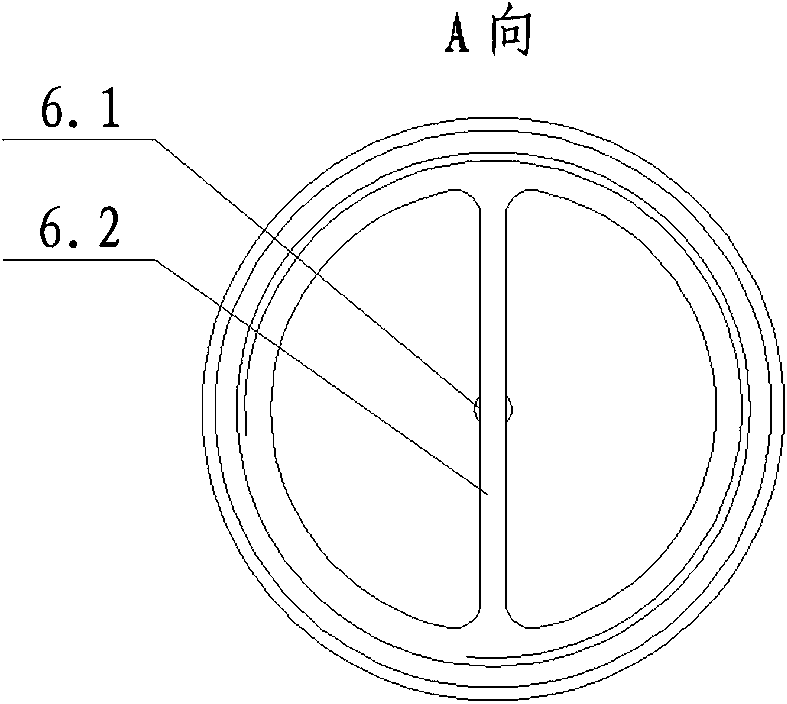

[0031] see figure 2 , image 3 and Figure 4 , the decompression mechanism includes a tubular sliding sleeve 2 with shoulders, a positioning ring 2.1 is arranged in the middle of the sliding sleeve 2 with shoulders, and an air inlet nozzle 1 is fixedly installed inside the sliding sleeve 2 with shoulders on the upper part of the positioning ring 2.1. 2.1 There are four primary diffuser holes 18 on the side wall of the lower sliding sleeve 2 with shoulders; the bottom surface of the positioning ring 2.1 is provided with a sealing ring groove, and a decompression sealing gasket 3 is installed in the sealing ring groove; the lower part of the primary diffuser hole 18 The belt shoulder sliding sleeve 2 is threadedly connected to the disk-shaped decompression spring bracket 6, and the middle part of the inner surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com