Progressive rope gripper and progressive overspeed protection safety device for dragging type lifting device

A technology for lifting equipment and overspeed protection, which is applied in the direction of elevators, transportation and packaging, etc. It can solve problems such as unstable braking distance, damage to transmission parts and main stressed structural parts, and no buffer, so as to avoid the construction cage from falling, The effect of good safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

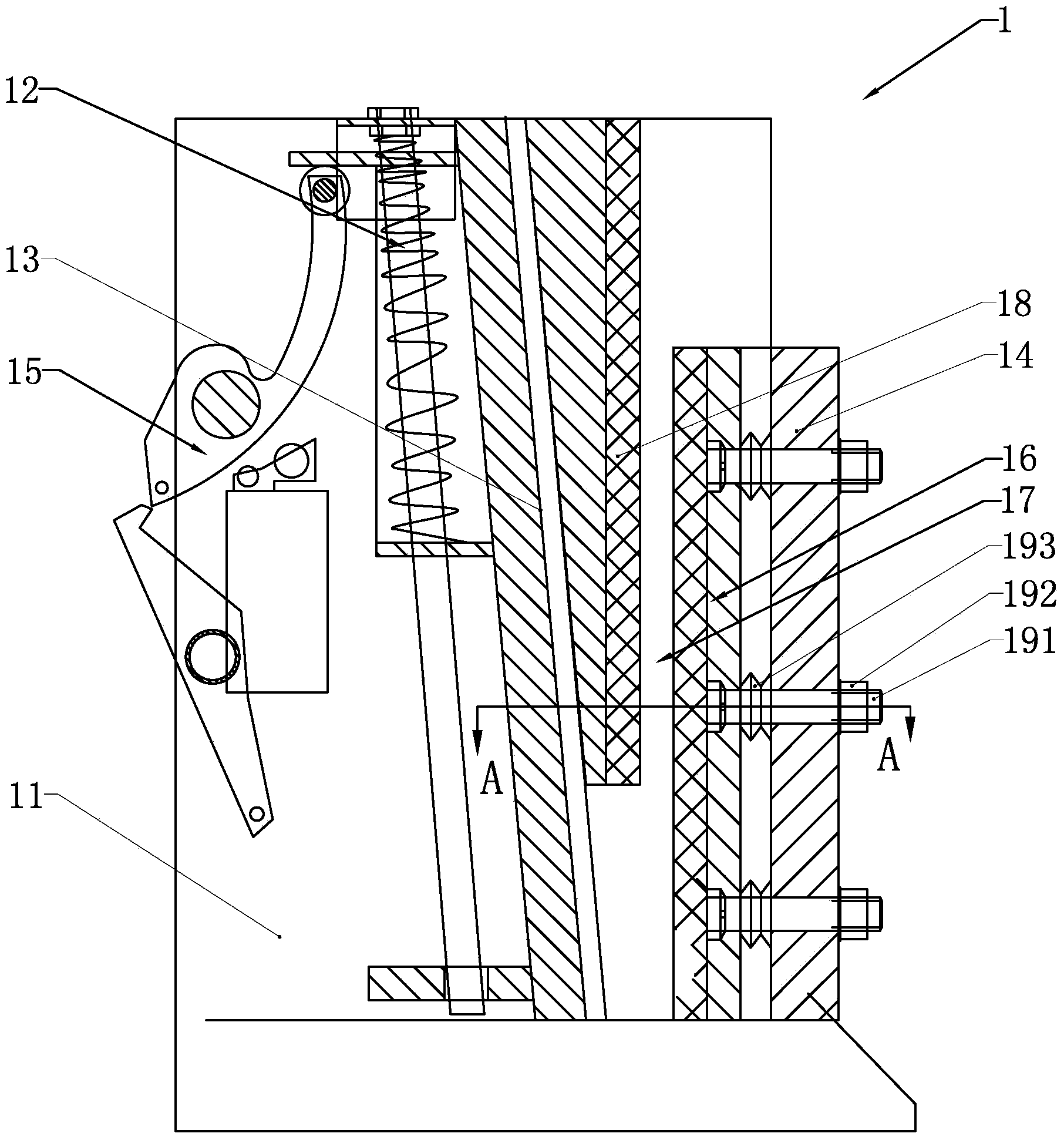

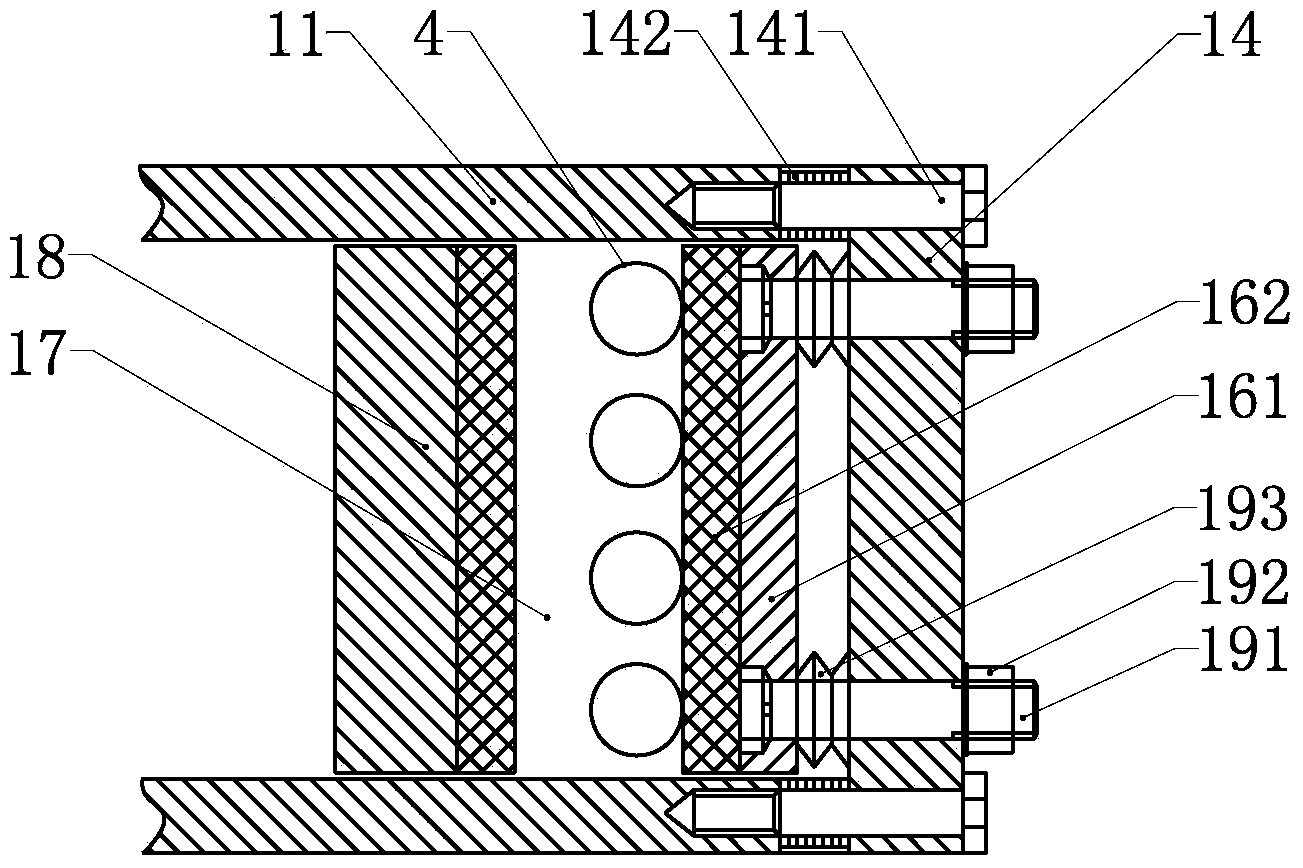

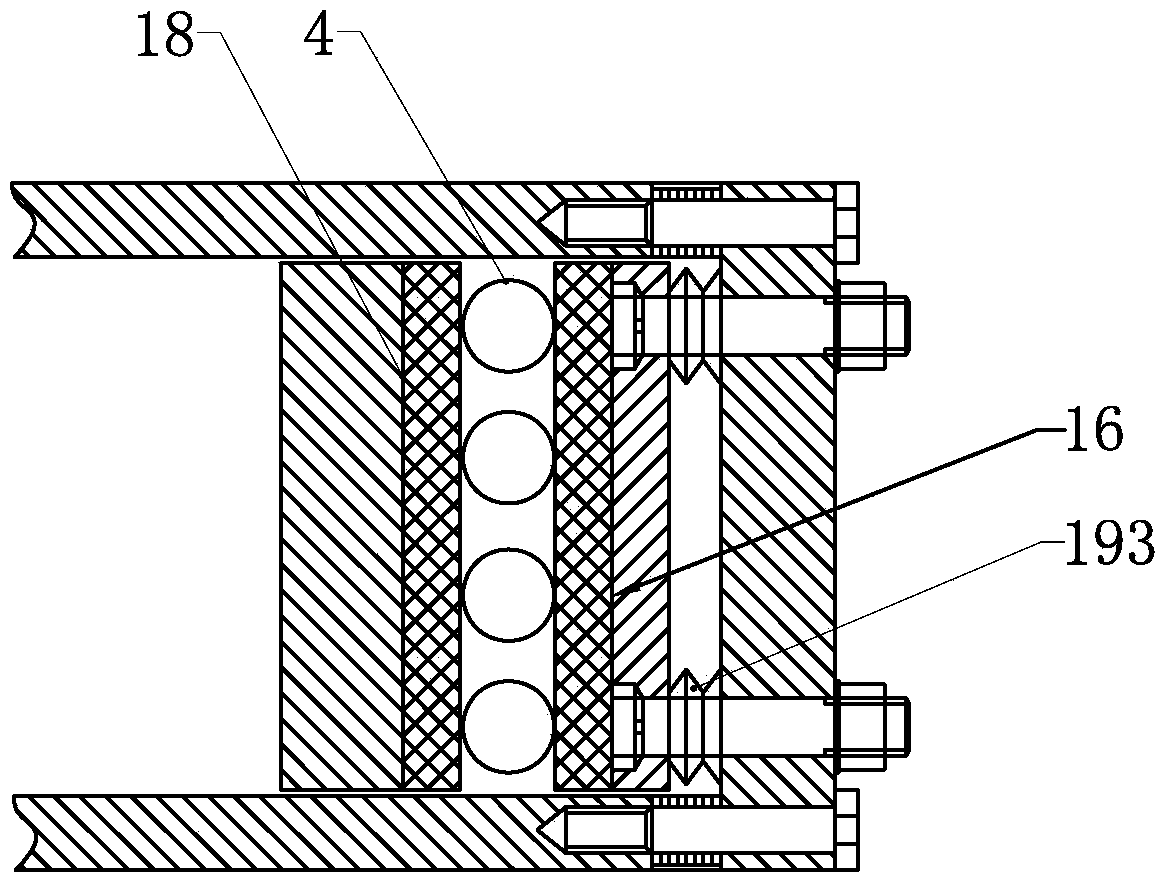

[0026] Such as Figure 1 to Figure 3 As shown, the progressive rope clamp 1 of the present invention has a frame body 11 on which two energy storage spring mechanisms 12, a fixed plate 14, a decoupling mechanism 15, a custom moving plate 16 and a wedge-shaped movable brake plate 18. Wherein: the fixing plate 14 is connected to the frame body 11 through a plurality of connecting screws 141 , and the connecting screws 141 between the fixing plate 14 and the frame body 11 are sleeved with a plurality of adjusting washers 142 . The fixed brake plate 16 is composed of a mounting steel plate 161 and a brake friction plate 162 , and the brake friction plate 162 is fixed on the inner end surface of the mounting steel plate 161 . The installation steel plate 161 is arranged on the inner side of the fixing plate 14 through an elastic sliding assembly. The elastic sliding assembly consists of ten guide rods 191 , ten locking elements 192 and ten groups of elastic elements 193 . Ten gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com