After-loading bridge-wire protective sleeve

A technology of protective sleeve and bridge wire, which is applied in the field of post-loading bridge wire protective sleeve, which can solve the problem of easy damage of bridge wire and achieve the effect of convenient drug application operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

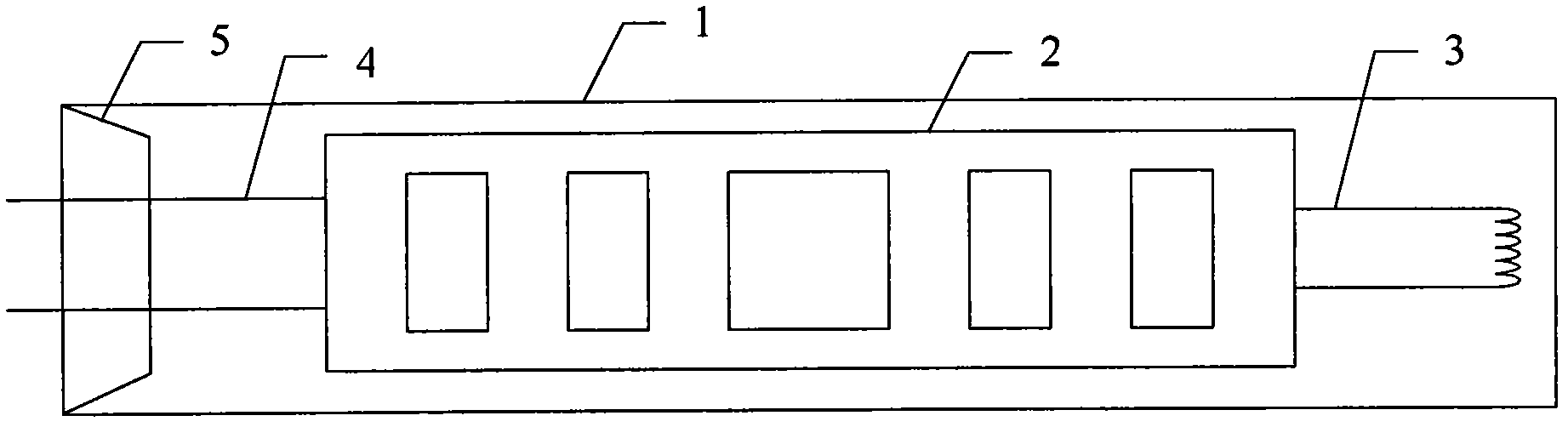

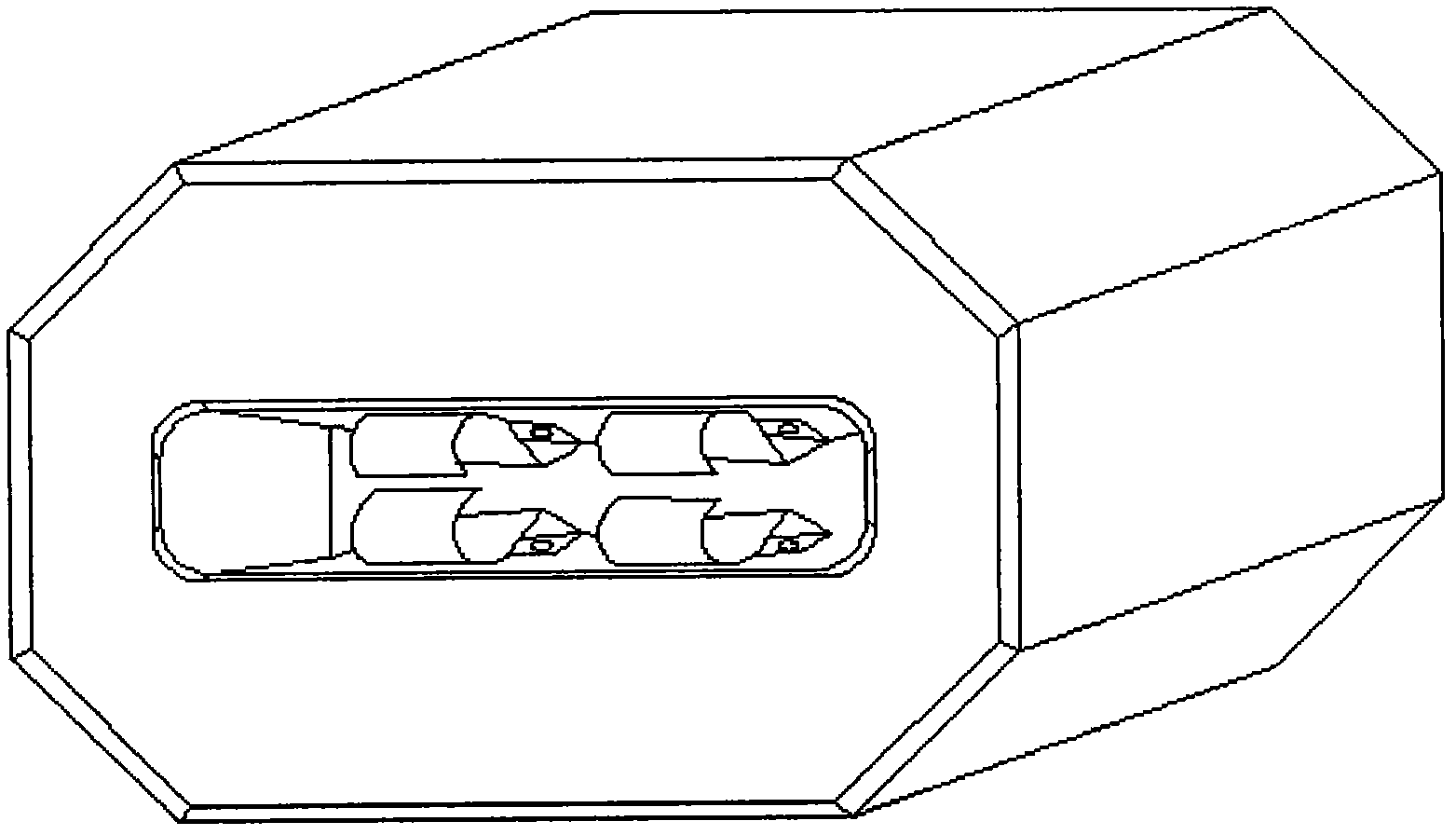

[0017] Such as figure 2 Shown is a perspective view of the front of the protective cover of the present invention.

[0018] The protective cover includes a shell and a metal sheet.

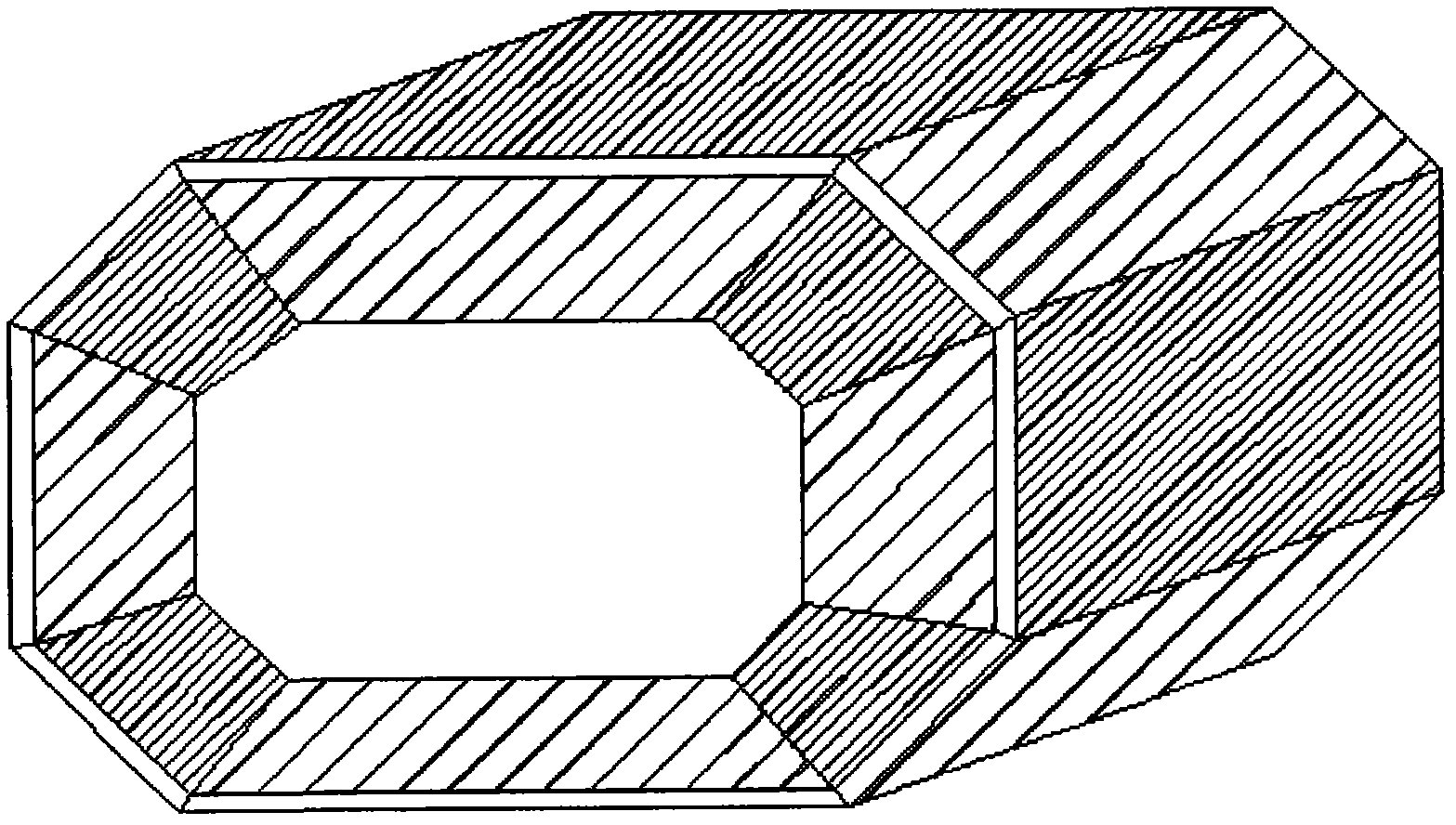

[0019] Such as image 3 Shown is a perspective view of the back of the protective cover of the present invention.

[0020] Both ends of the shell are open, one end is open to cover the circuit board, and the other end is open for the bridge wire to apply medicine.

[0021] Such as Figure 4 Shown is a cross-sectional view of the protective sleeve of the present invention.

[0022] There are two pairs of metal sheets, and the two metal sheets of each pair are respectively located at corresponding positions on the upper and lower inner surfaces of the casing.

[0023] Such as Figure 5 Shown is a schematic diagram of the corresponding relationship between the metal sheet and the circuit board contained in the protective case of the present invention.

[0024] One end of the metal sheet is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com