Rotating around optical axis alignment error analysis method

A technology of alignment error and optical axis rotation, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of complex structure and device, difficult to realize, and difficult to adjust, so as to simplify the detection device and improve the alignment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

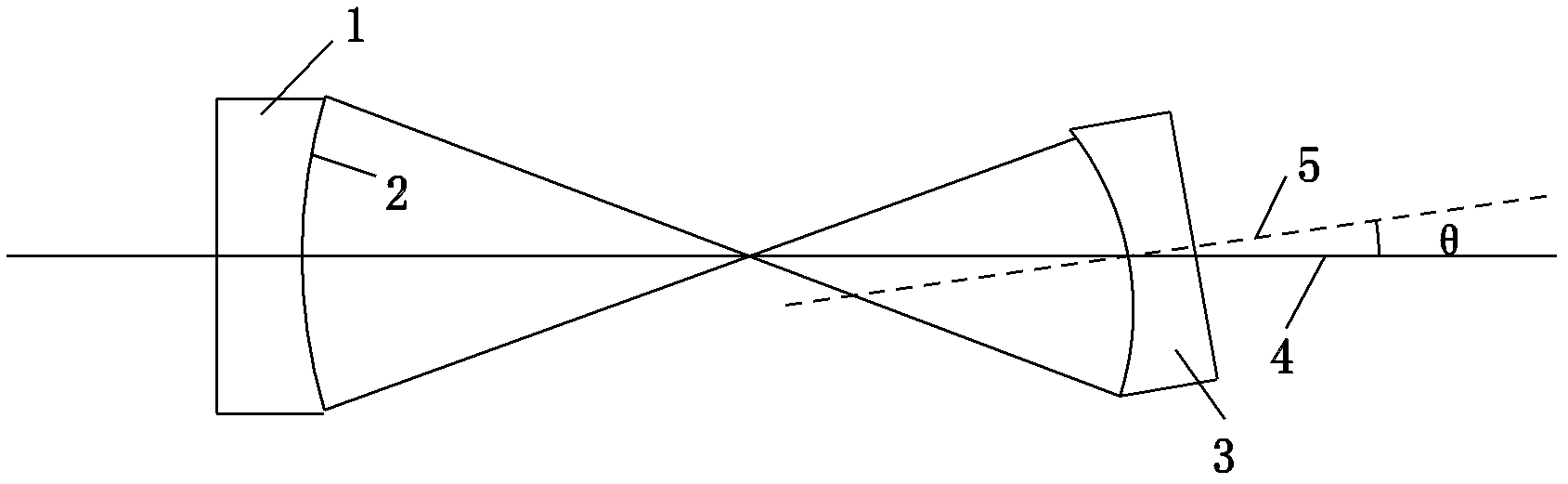

[0036] The specific implementation method is combined with the attached Figure 2-4 to illustrate.

[0037] The procedure for the analysis of alignment errors when rotating around the optical axis in absolute detection:

[0038] 1) Adjust the detection device of the optical element under test so that the optical element under test and the reference surface are in a confocal position, that is, the centers of curvature of the two coincide. At this time, M times (M can be taken as 50) repeated measurements are carried out on the optical element under test; according to the PV and RMS values of the measured data, PV refers to the difference between the maximum value and the minimum value in the surface shape data, and RMS refers to the surface shape data. The root mean square value of the data, the gross error elimination principle, the Leite criterion, the gross error in the M measurement data is eliminated, and the average result of all the measurement data (M1 times) after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com